A kind of n-cds@δ-mno 2 Preparation method and application of nanocomposite materials

A nanocomposite material, n-cds technology, applied in the field of preparation of N-CDs@δ-MnO2 nanocomposite materials, can solve the problems of low operation safety, complicated preparation process, long preparation time, etc., to achieve safety Good, simple and easy to operate, improve the effect of adsorption and degradation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of carbon quantum dots (N-CDs):

[0041] (1.1) Weigh 5.000g of ammonium citrate and 1.000g of sodium dihydrogen phosphate, dissolve them in 10ml of distilled water, and sonicate for 5-10min to dissolve them completely;

[0042] (1.2) Microwave heating for 2-3min to evaporate the water, cool to a safe temperature of 25-30°C, take out the solid, dissolve it with a mixed solution of ethanol and water, sonicate for 5-10min, centrifuge, sonicate again for 5-10min, centrifuge, repeat 3 times Remove large insoluble particles for the first time;

[0043] (1.3) Take out the supernatant, add 10g of 732 strong-acid styrene cation exchange resin, let stand for 5min, then filter with suction, and spin-evaporate the filtrate at 70°C until the solution is thick, pour it into a watch glass, and dry it at 80°C for 4h, Grinding to obtain the product N-CDs.

[0044] It is measured that the particle size of the prepared carbon quantum dots is between 3nm and 8nm.

[0045] f...

Embodiment 2

[0047] Synthesis of N-CDs@δ-MnO 2 Nanocomposites:

[0048] (2.1) Accurately weigh 0.15 g of the N-CDs prepared in Example 1, and dissolve them in 20 ml of distilled water with 0.45 g of potassium permanganate, and stir magnetically for 10 min;

[0049] (2.2) At the same time, take 1ml of concentrated hydrochloric acid and dissolve it in 20ml of water, add it dropwise to the potassium permanganate solution after dilution, and continue stirring for 20min;

[0050] (2.3) Put the solution obtained in step (2.2) into a microwave reactor, set the time to 10min, and the temperature to 100°C. After the reaction, cool to a safe temperature of 25-30°C, take it out, and suction filter to obtain yellow The brown solid was washed three times with ethanol and water, and dried at 60°C for 4 hours to obtain the product N-CDs@δ-MnO 2 nanocomposites.

[0051] For comparison, δ-MnO 2 It is also prepared by the same method as the above-mentioned composite material, the difference is that N-CD...

Embodiment 3

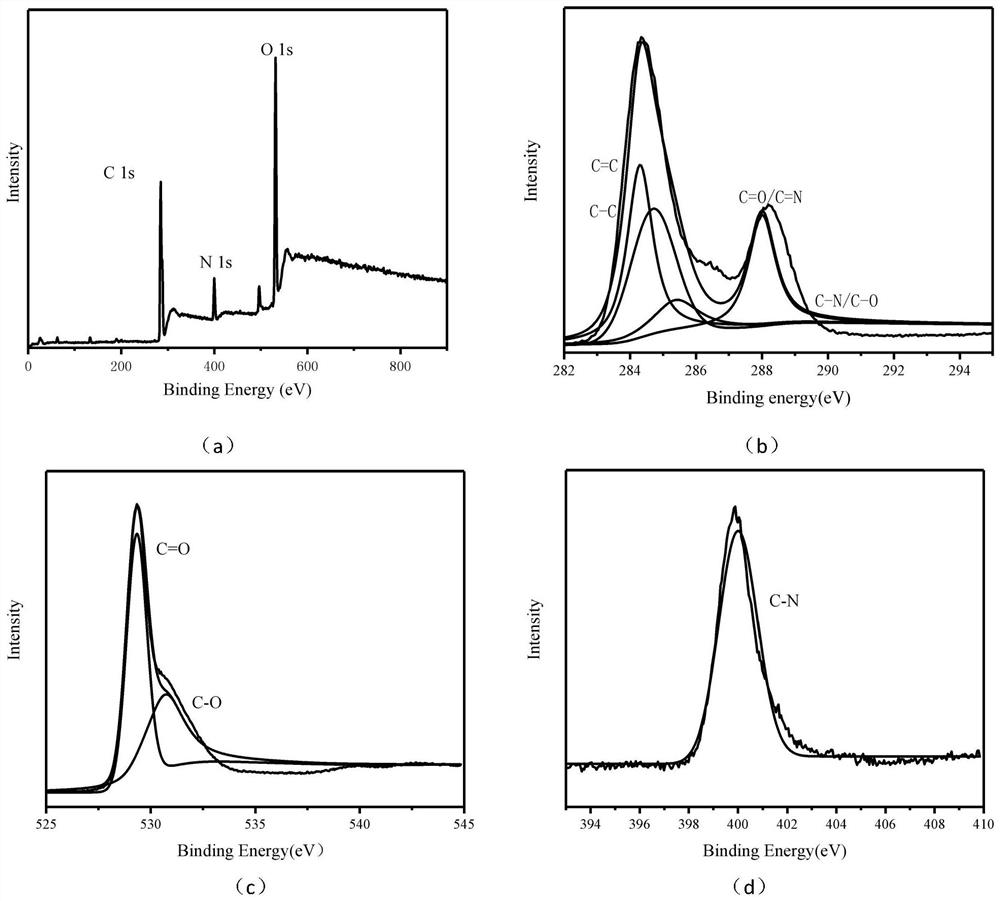

[0053] For the N-CDs and N-CDs@δ-MnO prepared in Examples 1 and 2 2 Nanocomposites and δ-MnO 2 Characterization and data analysis were performed.

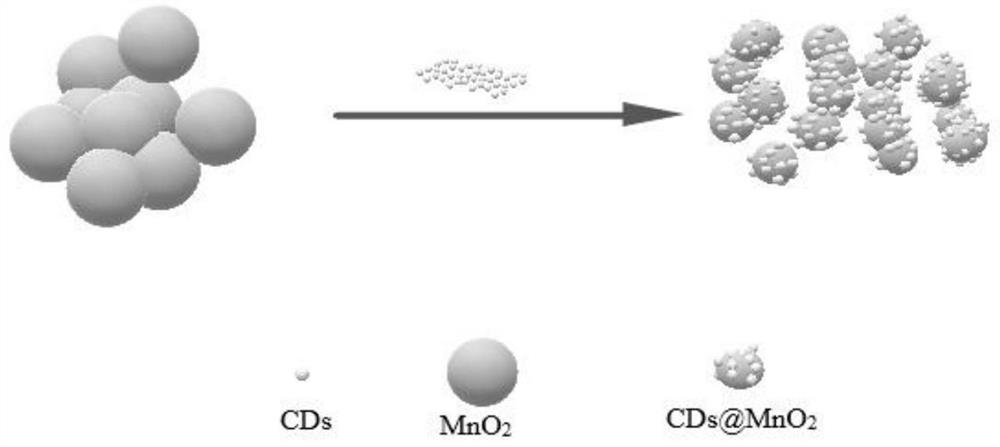

[0054] figure 2 For the prepared N-CDs@δ-MnO 2 Composite model diagram of nanocomposites. It can be seen that when N-CDs and δ-MnO 2 When composited, the composite N-CDs@δ-MnO 2 More dispersed, larger specific surface area.

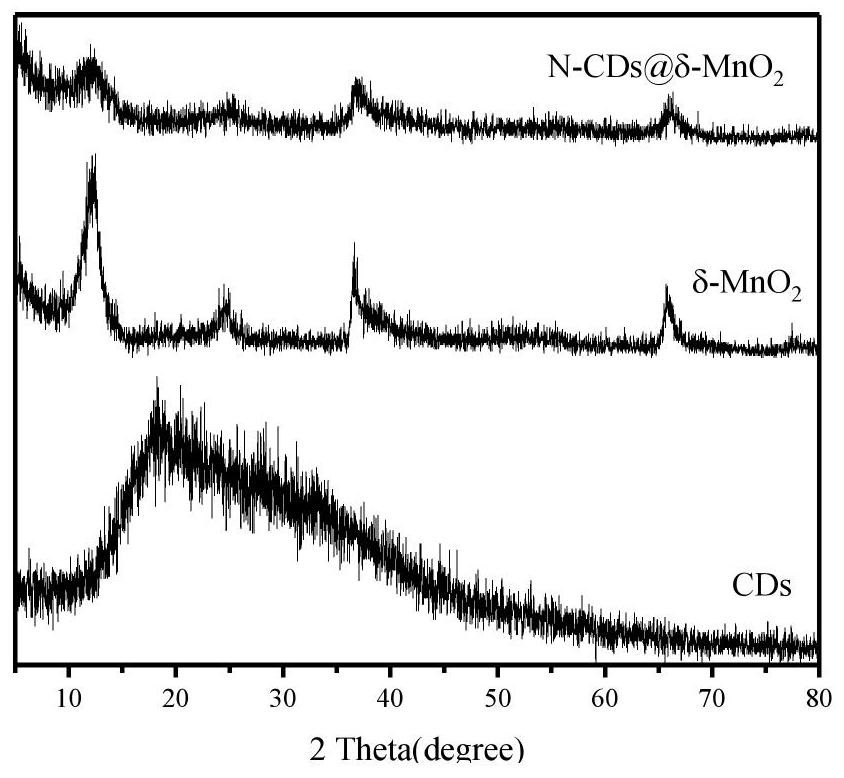

[0055] image 3 For the prepared N-CDs@δ-MnO 2 XRD patterns of nanocomposites. From the XRD spectrum of N-CDs in the figure, it can be seen that there is a broad diffraction peak around 2θ=20°, which is similar to the typical diffraction pattern of carbon dots, which means that N-CDs have an amorphous carbon structure, confirming that formation of carbon dots.

[0056] From the figure δ-MnO 2 It can be seen from the XRD spectrum that the four crystal plane diffraction peaks located at 2θ=12.340°, 2θ=24.799°, 2θ=37.371°, and 2θ=66.859° correspond to the diffraction peaks in the PDF#52-0556 card numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com