Preparation and application of modified straw fiber adsorption material

A technology for modifying straws and adsorbent materials, which is applied in the fields of adsorbed water/sewage treatment, other chemical processes, water/sludge/sewage treatment, etc. Low energy consumption, easy availability of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

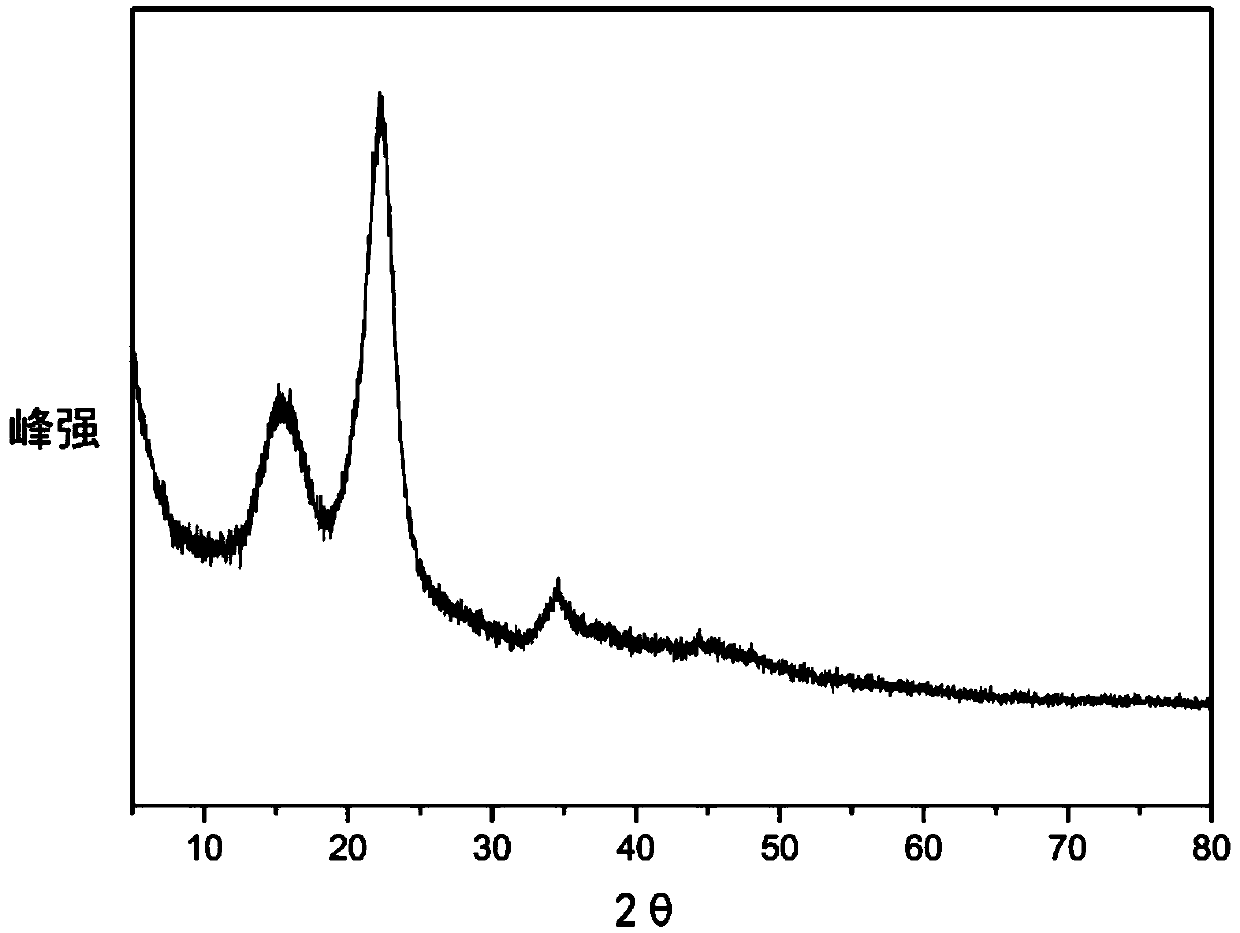

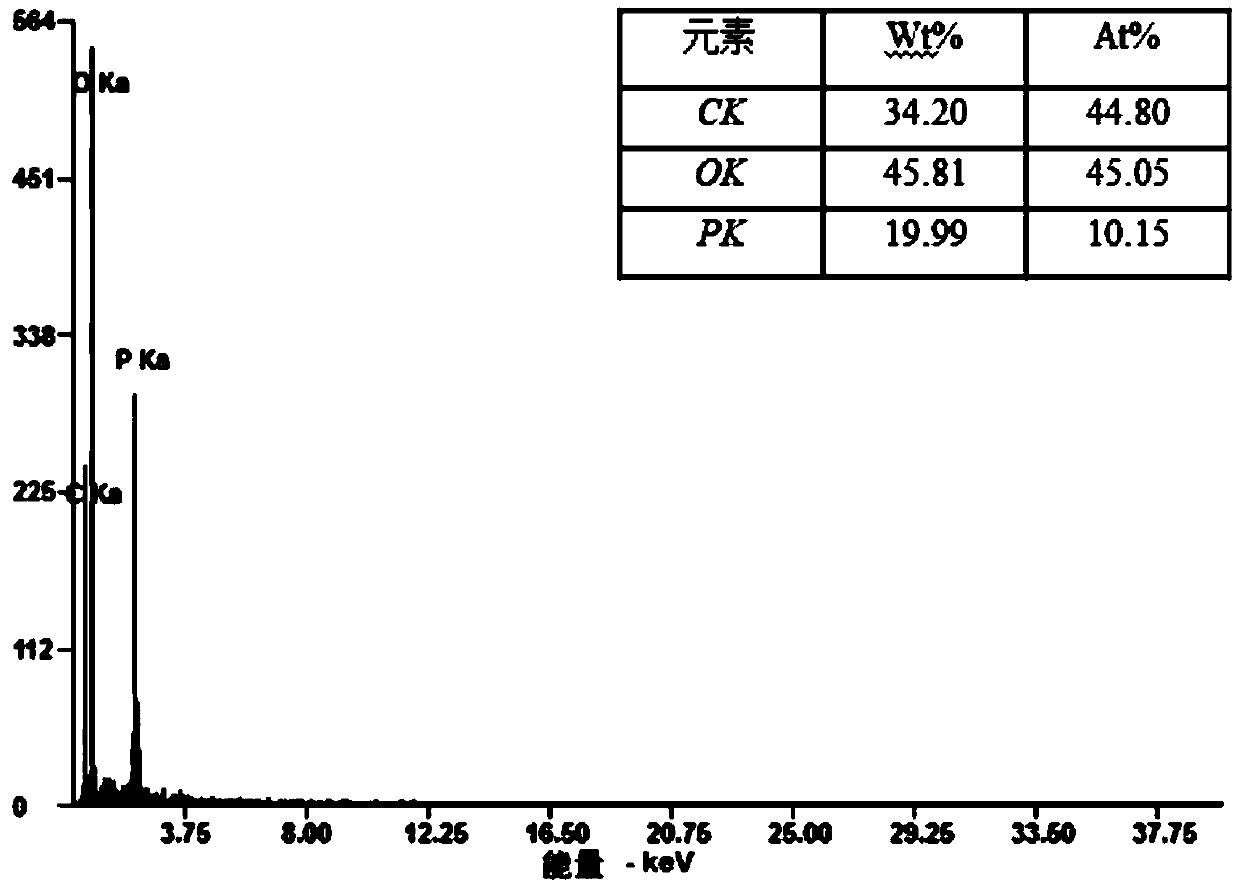

[0051] The preparation of a modified straw fiber adsorption material comprises the following steps:

[0052] 1) Wash, dry, pulverize, sieve and sieve corn stalks to obtain corn stalk powder with a particle size of 0.45mm, immerse it in 1mol / L sodium hydroxide solution at room temperature, soak for 24h, and then Continue to wash with deionized water during the suction filtration process of the vacuum filtration pump until the pH of the filtrate is neutral, and drain;

[0053] 2) Add an etherification agent of acrylonitrile solution with a mass fraction of 98% to the corn stalk sample after the above treatment until the corn stalk sample is completely submerged, wrap the beaker with tin foil, and perform etherification reaction at 30°C for 1 hour in a constant temperature water bath, and then Use a vacuum filter pump to filter out the acrylonitrile solution, then wash with deionized water to remove excess acrylonitrile solution;

[0054] 3) Add a diethylenetriamine / ethylene gly...

Embodiment 2~5

[0058] The operating steps are the same as in Example 1, and the raw materials and reaction conditions are set in Table 1 below, and those not mentioned in Table 1 are consistent with Example 1:

[0059]

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com