rGO/Fe<3+>/g-C3N4 ternary composite photocatalyst and preparation method thereof

A photocatalyst and ternary composite technology, applied in the field of photocatalytic materials, can solve the problems of low utilization rate of sunlight, high recombination rate of photogenerated carriers, and small specific surface area, so as to improve the catalytic activity of visible light and broaden the range of photoresponse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 prepares rGO / Fe 3+ / g -C 3 N 4 Ternary Composite Photocatalyst

[0032] Preparation of rGO / Fe 3+ / g -C 3 N 4 Ternary composite photocatalyst, according to the following steps:

[0033] (1) Fe-C 3 N 4 Preparation of photocatalyst

[0034] Take a certain amount of iron nitrate nonahydrate and dissolve it in deionized water, add melamine, wherein the quality of the two is based on Fe and g-C 3 N 4 The mass ratio ranges from 0.1 to 3%, weighed, stirred for 0.5h, and dried in an oven at 80°C for 24h. Then use an agate mortar to grind the dried solid into powder and put it into a muffle furnace, control the calcination temperature to 550°C, and the calcination time to 2h, and grind the air-cooled solid to obtain Fe-C 3 N 4 catalyst of light. At the same time, the sample without Fe was used as a control.

[0035] (2) Protonated Fe-C 3 N 4 catalyst of light

[0036] The resulting Fe-C 3 N 4 Add the powder into 0.5mol / L hydrochloric acid solution,...

Embodiment 2

[0039] Implementation of 2 sample testing

[0040] Detect the sample prepared according to the method of Example 1:

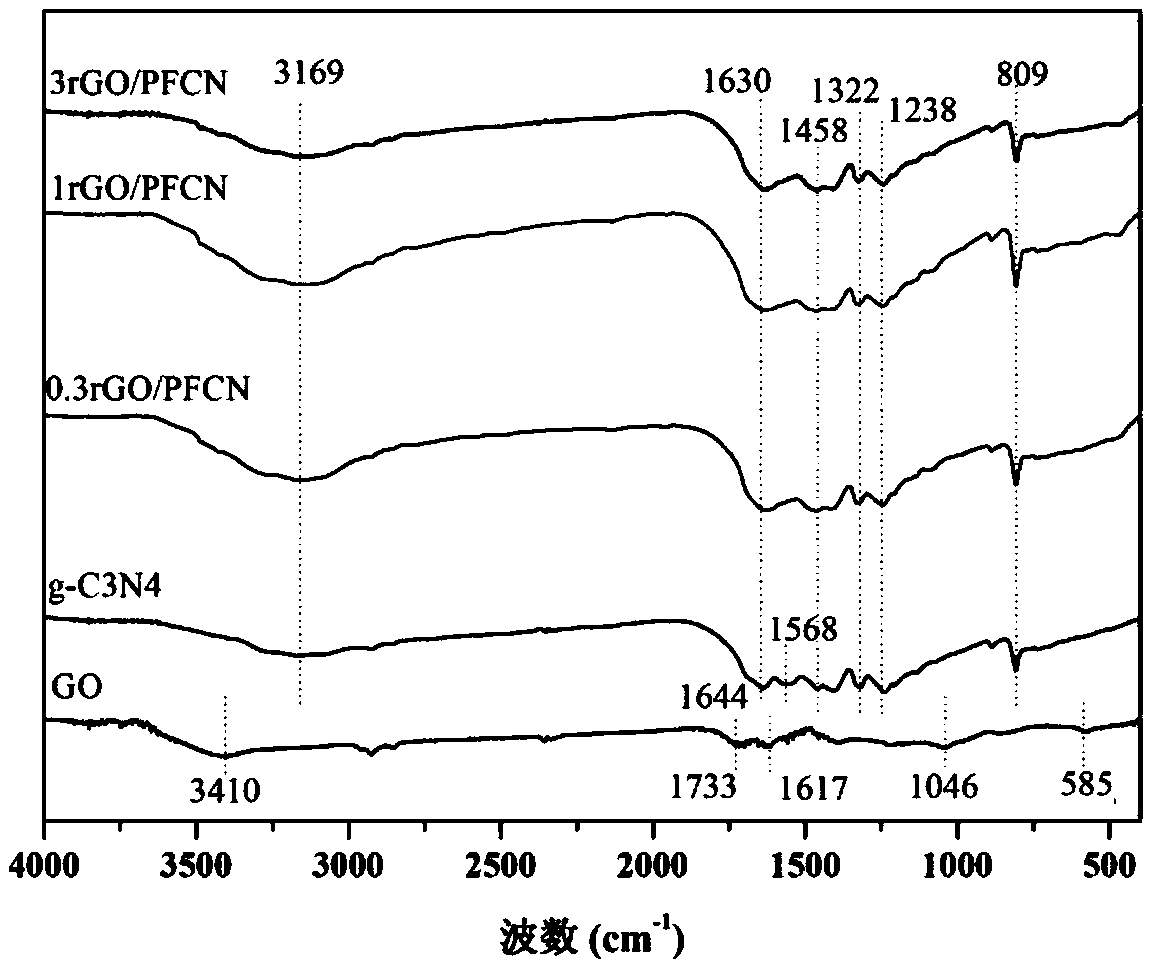

[0041] Microscopic characterization: Fourier transform infrared spectroscopy (FT-IR), scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS).

[0042] Optical properties: UV diffuse reflectance spectrum (UV-vis), observe the light absorption range and absorption intensity of different photocatalysts; photoluminescence spectrum (PL), the greater the fluorescence intensity, the higher the electron-hole recombination rate.

[0043] Evaluation of photocatalytic activity: Under the conditions of temperature 25°C, relative humidity 50%, and initial NO concentration of 1000ppb, a 250W metal halide lamp was selected as the light source for the photocatalytic degradation of NO reaction, and the photocatalytic degradation efficiency of different photocatalysts was tested to evaluate the photocatalytic activity. size of catalytic activity.

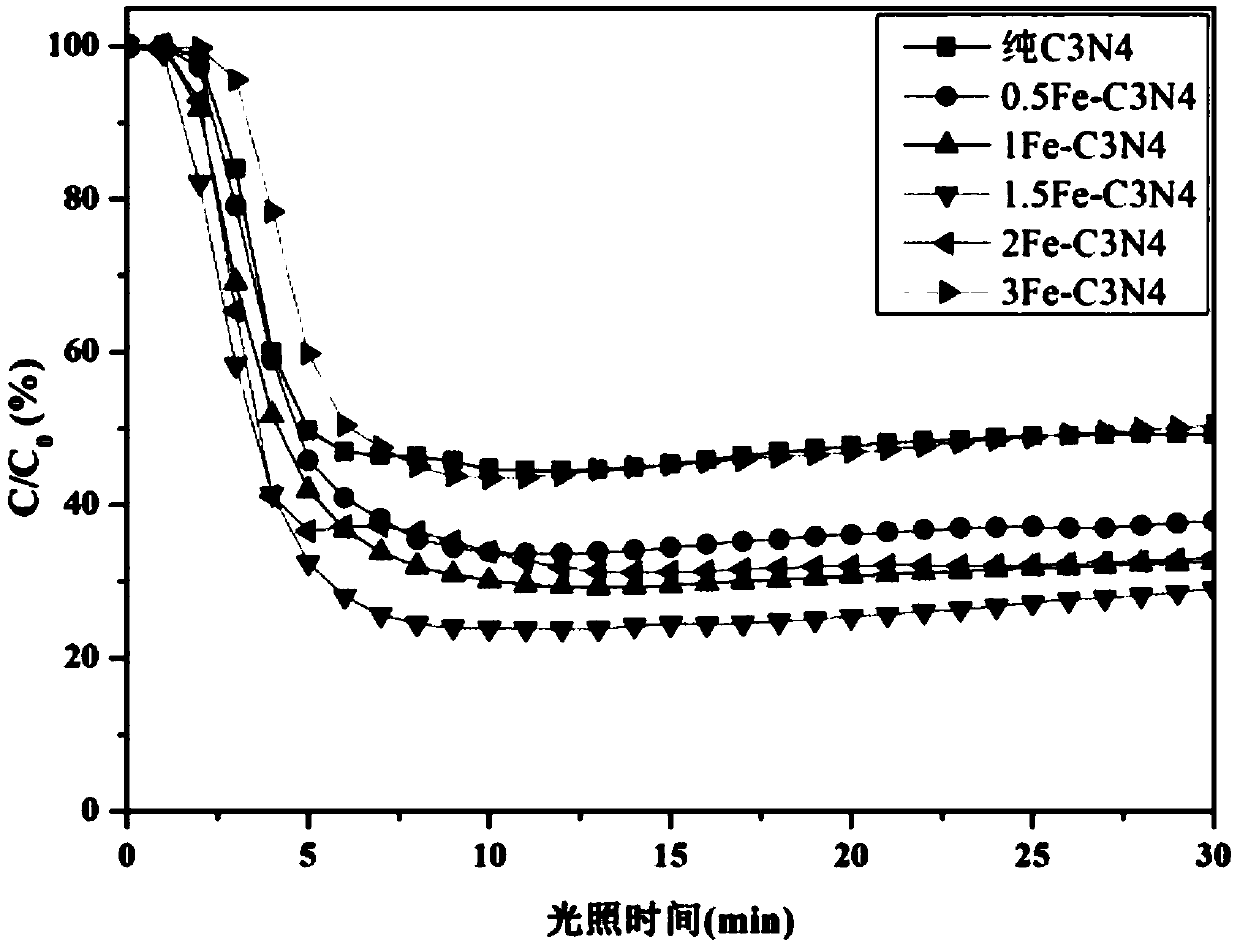

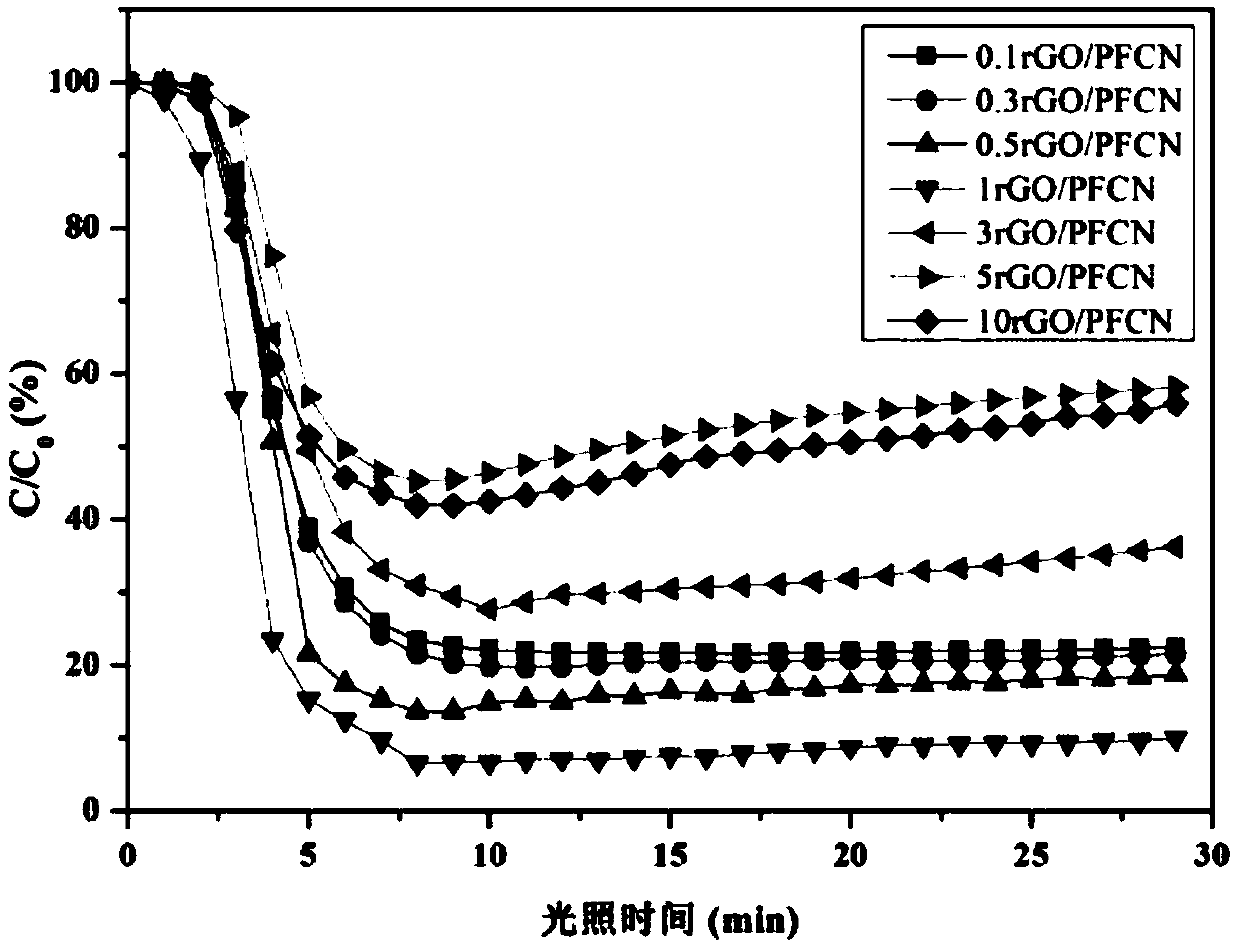

[0044] 1. Eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com