Anti-ultraviolet agent for textile fabric

A technology of anti-ultraviolet and textile fabrics, applied in the field of textile fabrics, can solve the problems of prone to burns, erythema or blisters, skin loss of resistance, etc., achieve long anti-ultraviolet time, high safety, good anti-ultraviolet effect, stability and timeliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

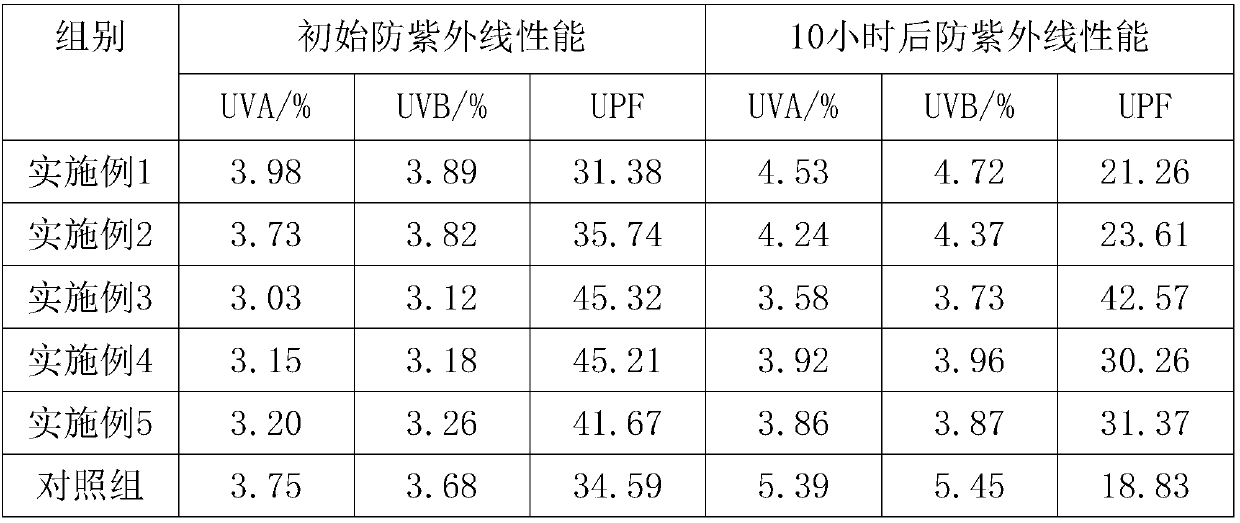

Examples

Embodiment 1

[0025] An anti-ultraviolet auxiliary agent for textile fabrics, made of the following raw materials in parts by weight: 45 parts of nano-silica, 5 parts of octyl methoxycinnamate, 8 parts of cinnamate, 5 parts of activated carbon, cationic poly 4 parts of acrylamide, 3 parts of dipropylene glycol methyl ether, 1 part of polyvinyl alcohol, 1 part of glycerol stearic acid, 0.5 parts of cyclomethicone, 0.3 parts of menthol, 0.2 parts of phenoxyethanol, deionized water 120 servings.

[0026] The preparation method of the anti-ultraviolet auxiliary agent for textile fabrics comprises the steps of:

[0027] (1) Grinding the activated carbon to a size of 60um, adding octyl methoxycinnamate, cinnamate, and cationic polyacrylamide, and treating it with microwaves with a frequency of 2450MHz and a power of 700W for 15min to obtain substance I;

[0028] (2) Mix dipropylene glycol methyl ether and polyvinyl alcohol, heat to 120°C, heat-preserve, stir and mix for 10 minutes, then add glyc...

Embodiment 2

[0032] An anti-ultraviolet auxiliary agent for textile fabrics, made of the following raw materials in parts by weight:

[0033] 75 parts of modified nano powder glue, 12 parts of octyl methoxy cinnamate, 15 parts of cinnamic acid salt, 10 parts of activated carbon, 9 parts of cationic polyacrylamide, 6 parts of dipropylene glycol methyl ether, 5 parts of polyvinyl alcohol, glycerin stearin 3 parts acid, 2 parts cyclomethicone, 2 parts menthol, 1 part phenoxyethanol, 150 parts deionized water.

[0034] The modified nano powder glue is made of nano silicon dioxide, titanium dioxide, zinc oxide, silicone oil and citric acid. The specific preparation method is: mixing nano silicon dioxide, titanium dioxide, zinc oxide, silicone oil and citric acid, adding Water ethanol and 95wt% concentrated sulfuric acid are stirred and mixed with a stirrer, the stirring speed is 1000r / min, and the stirring time is 10 minutes. After the stirring is completed, let it stand for 20 minutes, and the...

Embodiment 3

[0042] An anti-ultraviolet auxiliary agent for textile fabrics, which is made of the following raw materials in parts by weight: 60 parts of modified nano-powder glue, 9 parts of octyl methoxycinnamate, 12 parts of cinnamic acid salt, 8 parts of activated carbon, cation 7 parts of polyacrylamide, 5 parts of dipropylene glycol methyl ether, 3 parts of polyvinyl alcohol, 2 parts of glycerol stearic acid, 1.2 parts of cyclomethicone, 1 part of menthol, 0.6 parts of phenoxyethanol, deionized 140 parts of water.

[0043] The modified nano-powder glue is made of nano-silicon dioxide, titanium dioxide, zinc oxide, silicone oil and citric acid. The specific preparation method is: add absolute ethanol dropwise to the nano-silicon dioxide under stirring until it is completely dissolved. Mix titanium dioxide and zinc oxide, add deionized water dropwise until completely dissolved, then add ethanol solution of nano silicon dioxide, silicone oil and 95wt% concentrated sulfuric acid to titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com