Composite negative electrode material for lithium batteries and preparation method thereof

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory high-current discharge performance, poor high-rate charge-discharge performance, specific capacity decay, etc., to achieve cycle performance and improve Conductivity, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

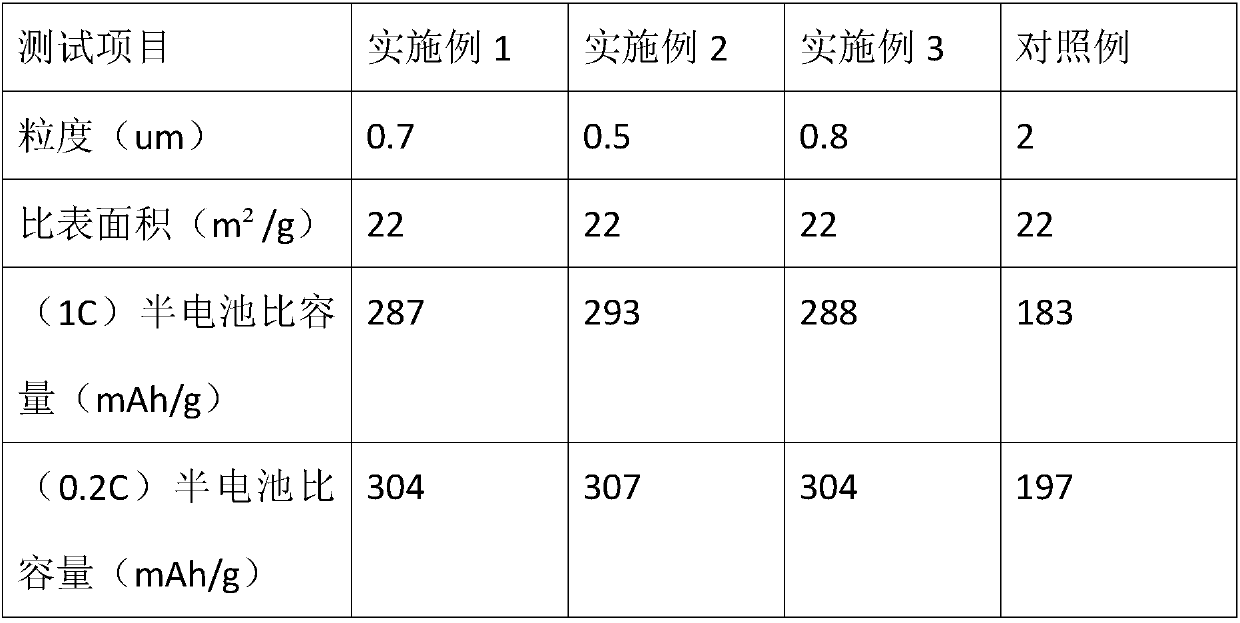

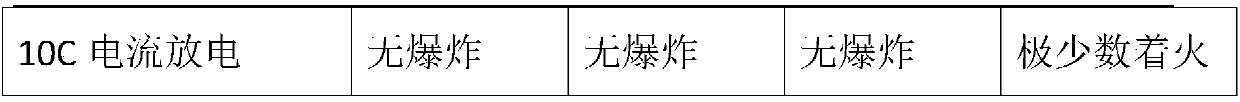

Examples

Embodiment 1

[0018] 1) Manganese carbonate, lithium titanate, and cobalt oxide are mixed uniformly according to the molar ratio of elements Mn:Li:Co=1.6:0.621:0.2, put into a stirring ball mill for mechanical activation, and pass through a 300-mesh sieve after drying;

[0019] 2) In terms of parts by mass, 20 parts of nano-silicon, 80 parts of amorphous carbon, and 200 parts of N-methylpyrrolidone were dispersed by ultrasonic wave for 20 minutes and stirred evenly, and the product sieved in step 1) was mixed with the nano-silicon solution Evenly, place it in a roller furnace for calcination under the protection of nitrogen for 4 hours, the calcination temperature is 600°C, and cool down naturally;

[0020] 3) Put the naturally cooled powder into a ball mill for ball milling. After the ball milling is completed, place it in a roller furnace again, and calcinate for 2 hours under the protection of nitrogen at a calcining temperature of 1000°C. Cool naturally, demagnetize and sieve to obtain t...

Embodiment 2

[0023] 1) Manganese carbonate, lithium titanate, and cobalt oxide are mixed uniformly according to the molar ratio of elements Mn:Li:Co=1.6:0.621:0.2, put into a stirring ball mill for mechanical activation, and pass through a 300-mesh sieve after drying;

[0024] 2) In terms of parts by mass, 30 parts of nano-silicon, 90 parts of amorphous carbon, and 210 parts of N-methylpyrrolidone were dispersed by ultrasonic wave for 20 minutes and stirred evenly, and the product sieved in step 1) was mixed with the nano-silicon solution Evenly, place it in a roller furnace for calcination under the protection of nitrogen for 5 hours, the calcination temperature is 650°C, and cool down naturally;

[0025] 3) The naturally cooled powder was put into a ball mill for ball milling. After the ball milling was completed, it was placed in a roller furnace again, and calcined for 3 hours under the protection of nitrogen. The calcining temperature was 1250° C., cooled naturally, and the negative el...

Embodiment 3

[0028] 1) Manganese carbonate, lithium titanate, and cobalt oxide are mixed uniformly according to the molar ratio of elements Mn:Li:Co=1.6:0.621:0.2, put into a stirring ball mill for mechanical activation, and pass through a 300-mesh sieve after drying;

[0029] 2) In terms of parts by mass, 40 parts of nano-silicon, 100 parts of amorphous carbon, and 220 parts of N-methylpyrrolidone were dispersed by ultrasonic wave for 20 minutes and stirred evenly, and the product sieved in step 1) was mixed with the nano-silicon solution Evenly, place it in a roller furnace for calcination for 6 hours under the protection of nitrogen, and the calcination temperature is 700 ° C, and the temperature is naturally lowered;

[0030] 3) Put the naturally cooled powder into a ball mill for ball milling. After the ball milling is completed, place it in a roller furnace again and calcinate for 4 hours under the protection of nitrogen. The calcining temperature is 1300°C. Cool naturally, demagnetiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com