Typha orientalis presl carbon-loaded sodium vanadium phosphate nano composite material as well as preparation method and application thereof

A nano-composite material, sodium vanadium phosphate technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of accelerating reaction kinetics, easy control, and high discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

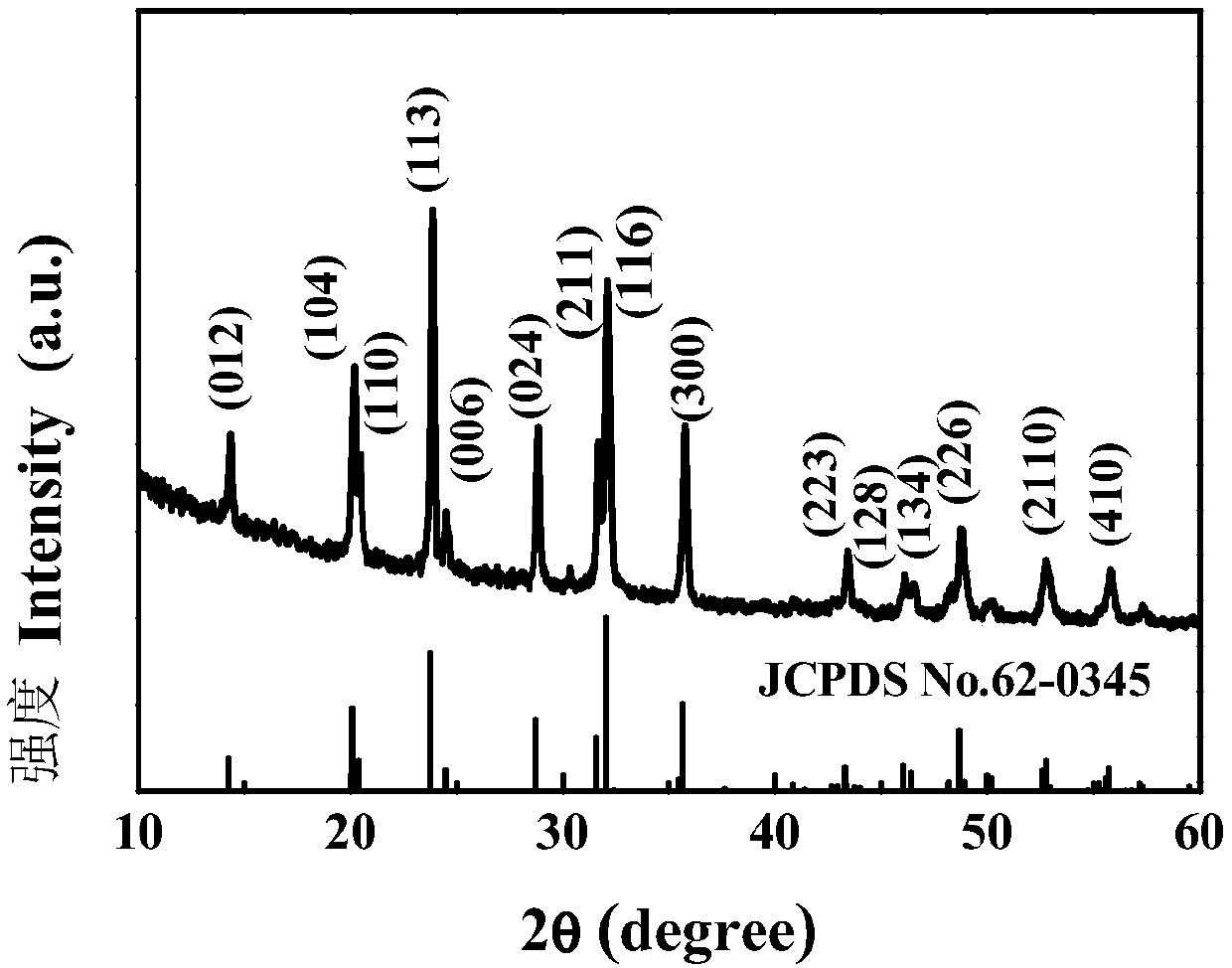

Embodiment 1

[0023] Put an appropriate amount of cattail in a porcelain boat, put it into a tube furnace for heat treatment under argon atmosphere to carbonize it, the reaction temperature is 600°C, the reaction time is 2 hours, and slowly cool to room temperature 25°C to obtain the loaded material cattail carbon. Dissolve 0.32g of vanadium trichloride in 10mL of deionized water, stir at room temperature 25°C to obtain a brown solution, then dissolve 0.36g of sodium dihydrogen phosphate and 0.36g of glucose in the above solution, and stir evenly to form a dark green solution. Then continue to stir for a period of time, and the resulting solution is ready for use; soak the prepared cattail carbon in the obtained dark green solution to make it fully infiltrated, then quickly freeze the resulting mixed solution under liquid nitrogen conditions, and then place it in a freeze dryer Dry in the middle for 24 hours to obtain the precursor; put the prepared precursor into a tube furnace for heat tre...

Embodiment 2

[0025] Put an appropriate amount of cattail in a porcelain boat, put it into a tube furnace for heat treatment under argon atmosphere to carbonize it, the reaction temperature is 600°C, the reaction time is 2 hours, and slowly cool to room temperature 25°C to obtain the loaded material cattail carbon. Dissolve 0.32g of vanadium trichloride in 10mL of deionized water, stir at room temperature 25°C to obtain a brown solution, then dissolve 0.36g of sodium dihydrogen phosphate and 0.36g of glucose in the above solution, and stir evenly to form a dark green solution. Then continue to stir for a period of time, and the resulting solution is ready for use; soak the prepared cattail carbon in the obtained dark green solution to make it fully infiltrated, then quickly freeze the resulting mixed solution under liquid nitrogen conditions, and then place it in a freeze dryer dry in the middle for 24 hours to obtain the precursor; put the prepared precursor into a tube furnace for heat tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reverse discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com