Preparation method and applications of carbon nano-tube-supported transition metal oxide material

A technology of carbon nanotubes and transition metals, applied in the field of material chemistry, can solve the problems of high cost and complicated process, and achieve the effect of low cost, simple preparation process and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

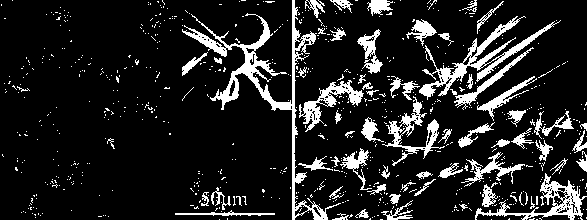

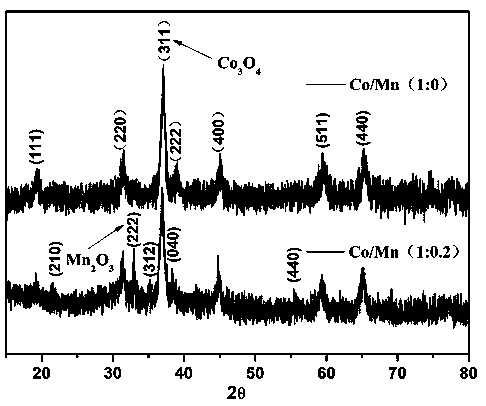

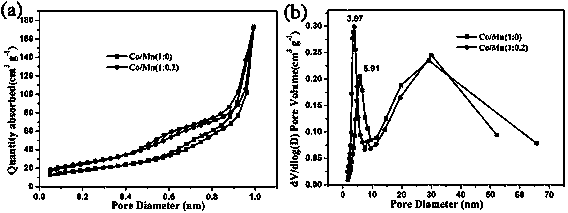

[0039] The preparation process of CNTs loaded transition metal oxide material containing Mn element doping is as follows:

[0040] (1) Anneal the CNTs. The annealing temperature of the carbon nanotubes is 500°C, the time is 30min, and the heating rate is 3°C / min. Then, dissolve, ultrasonic, and filter to form a film. The ultrasonic power of the carbon nanotubes is 225W, and the ultrasonic time is 30min ( Purpose: CNTs are evenly dispersed in the solution), and the suction filter carbon membrane is cut into a circular carbon membrane with a diameter of 12mm and a weight of about 1.2±0.05mg.

[0041] (2) Dissolve 1.74g of cobalt nitrate hexahydrate, 0.436g of nickel nitrate hexahydrate, 0.37g of ammonium fluoride, and 1.2g of urea in 80ml of deionized water, and form a pink solution under magnetic stirring;

[0042] (3) Add 0.151g of manganese chloride (at this time, the molar ratio of cobalt nitrate hexahydrate to manganese chloride is 1:0.2) into step 2), stir it with magnetic...

Embodiment 2

[0048] The preparation process of CNTs-loaded transition metal oxide materials containing different proportions of Mn doped is as follows:

[0049] (1) Anneal the CNTs. The annealing temperature of the carbon nanotubes is 500°C, the time is 30min, and the heating rate is 3°C / min. Then, dissolve, ultrasonic, and filter to form a film. The ultrasonic power of the carbon nanotubes is 225W, and the ultrasonic time is 30min ( Purpose: CNTs are evenly dispersed in the solution), and the suction filter carbon membrane is cut into a circular carbon membrane with a diameter of 12mm and a weight of about 1.2±0.05mg.

[0050] (2) Dissolve 1.74g of cobalt nitrate hexahydrate, 0.436g of nickel nitrate hexahydrate, 0.37g of ammonium fluoride, and 1.2g of urea in 80ml of deionized water, and form a pink solution under magnetic stirring.

[0051] (3) Add manganese chloride (at this time, the molar ratios of cobalt nitrate hexahydrate and manganese chloride are: 1:0.5, 1:0.1, 1:0.4 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com