Photocatalyst based on graphite phase carbon nitride g-C3N4, and preparation method and application thereof

A graphite-phase carbon nitride and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of high photogenerated electron-hole recombination rate, insufficient visible light absorption, and limited practical applications, etc. Problems, to achieve low cost, improve photocatalytic hydrogen production activity, and short operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Specific preparation method of HCNNS-300 photocatalyst

[0053] Using melamine as the precursor, roasting in the air, keeping it at 550°C for 4 hours, and then cooling down naturally, the bulk phase g-C 3 N 4 . Take a small amount of bulk g-C 3 N 4 In ethanol, the bulk phase g-C was passed through a cell disruptor 3 N 4 g-C stripped into few layers 3 N 4 Nanosheets, after drying, put them into an ultrasonic cleaner until they are dispersed in water, and then dry them to obtain g-C 3 N 4 Nanosheets. Will get g-C 3 N 4 Nanosheets in H 2 (10%) / N 2 (90%) roasting in a mixed gas, the temperature was raised to 300 °C at a heating rate of 5 °C / min, kept for 4 hours, and then the temperature was naturally lowered, that is, the HCNNS-300 photocatalyst was prepared.

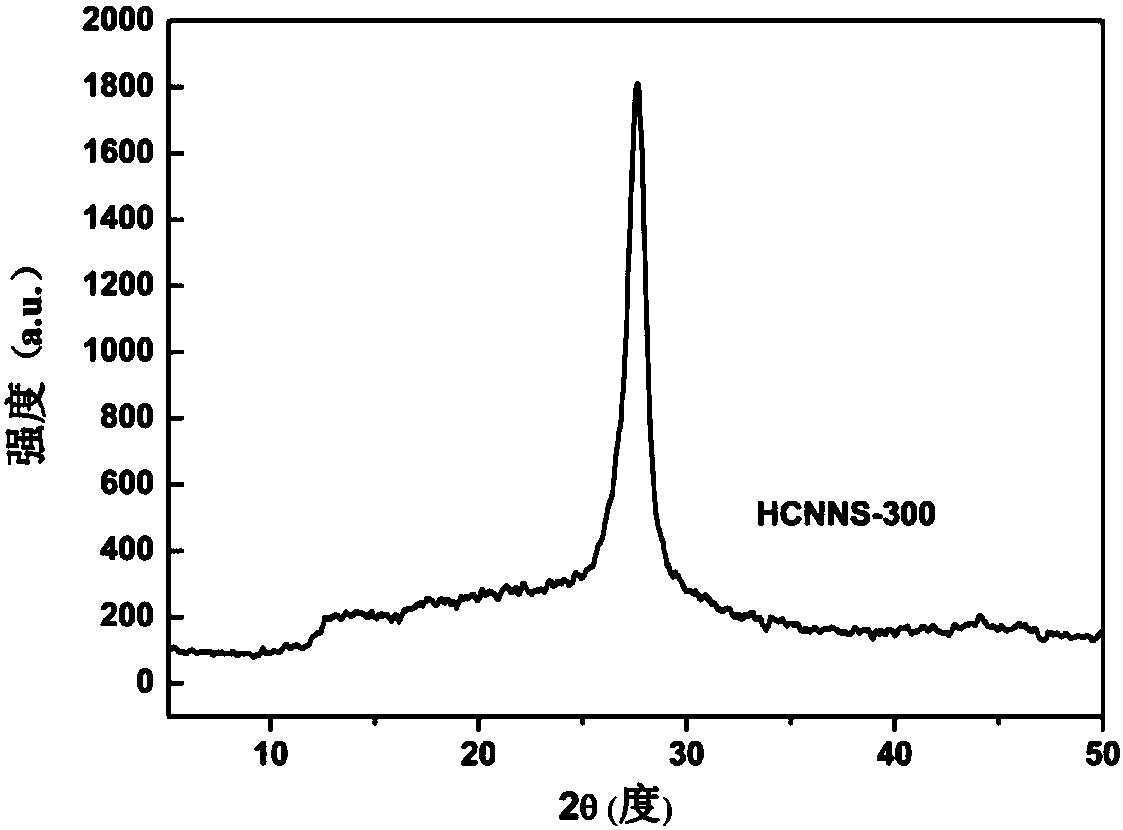

[0054] figure 1 It is the X-ray powder diffraction pattern of the photocatalyst prepared in Example 1. Depend on figure 1 It can be seen that the photocatalyst has only one characteristic diffractio...

Embodiment 2

[0057] Specific preparation method of HCNNS-450 photocatalyst

[0058] Using melamine as the precursor, roasting in the air, keeping it at 550°C for 4 hours, and then cooling down naturally, the bulk phase g-C 3 N 4 . Take a small amount of bulk g-C 3 N 4 In ethanol, the bulk phase g-C was passed through a cell disruptor 3 N 4 g-C stripped into few layers 3 N 4 After the nanosheets are dried, put them into an ultrasonic cleaner until they are completely dispersed in water, and then dry them to obtain g-C 3 N 4 Nanosheets. Will get g-C 3 N 4 Nanosheets in H 2 (10%) / N 2 (90%) roasting in a mixed gas, raising the temperature to 450°C at a heating rate of 5°C / min, keeping it for 4 hours, and then cooling down naturally, that is, the HCNNS-450 photocatalyst was prepared.

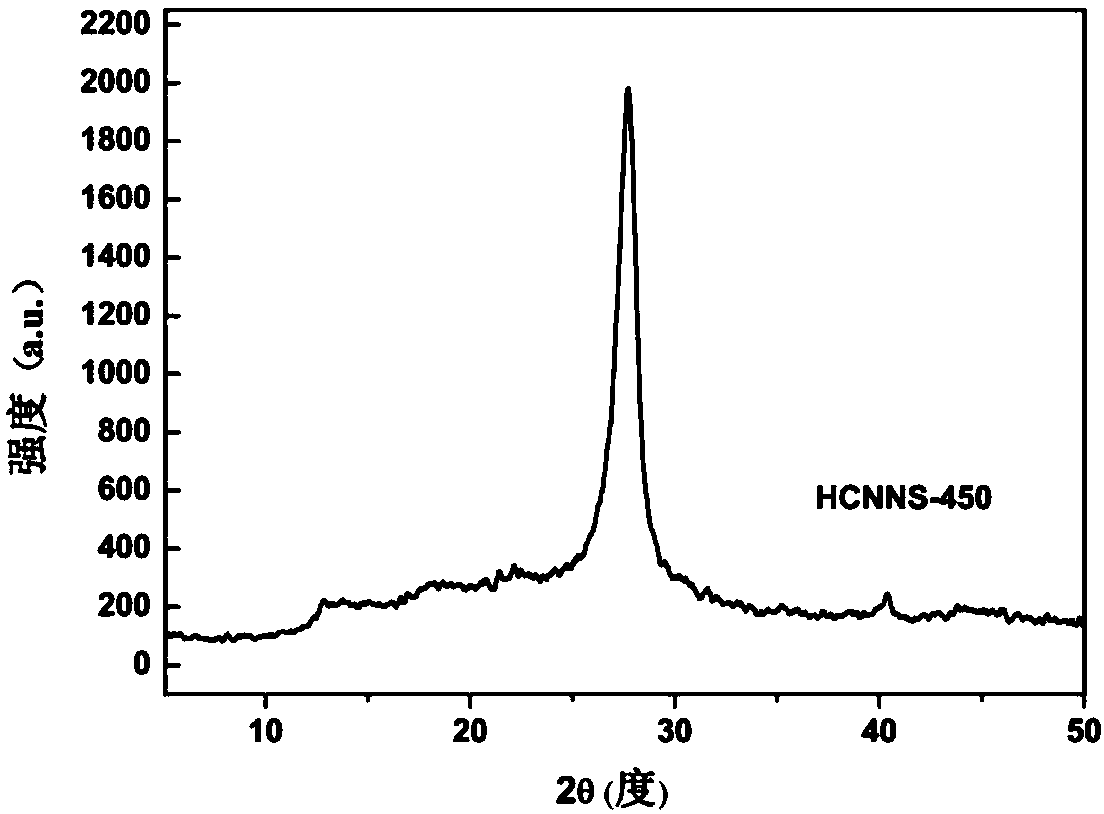

[0059] figure 2 It is the X-ray powder diffraction pattern of the photocatalyst prepared in Example 2. Depend on figure 2 It can be seen that the photocatalyst has only one characteristic diffr...

Embodiment 3

[0062] Hydrogen yield test of photocatalyst

[0063] Add 90 milliliters of deionized water, 10 milliliters of triethanolamine, 10 milligrams of the photocatalysts prepared in the above-mentioned examples 1 and 2, and add 33 microliters of chloroplatinic acid (Pt load is 1.56wt% ), cover the reaction kettle, evacuate with a vacuum pump while stirring until no bubbles are produced in the liquid, and irradiate with a 300W xenon lamp (UV cut 420 filter). Sampling once per hour, sampling six times, the sample gas chromatograph 9790II, record the peak area, calculate the hydrogen production and hydrogen production rate. See results Figure 5 .

[0064] The result shows: in the embodiment of the present invention, HCNNS-300 photocatalyst, HCNNS-450 photocatalyst and g-C 3 N 4 The hydrogen production rate of the nanosheets is 670.97 μmol g -1 h -1 , 1689.51 μmol g -1 h -1 , 255.66 μmol g -1 h -1 .

[0065] According to the above results, it is shown that the hydrogen produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com