High-barrier biodegradable mulch film and preparation method thereof

A biodegradable, high-barrier technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, plant protection, etc., can solve problems such as the inability to meet the needs of crop growth, poor barrier properties of mulch products, and difficult processing, and achieve good biodegradation. properties, high melting point and strength, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 3

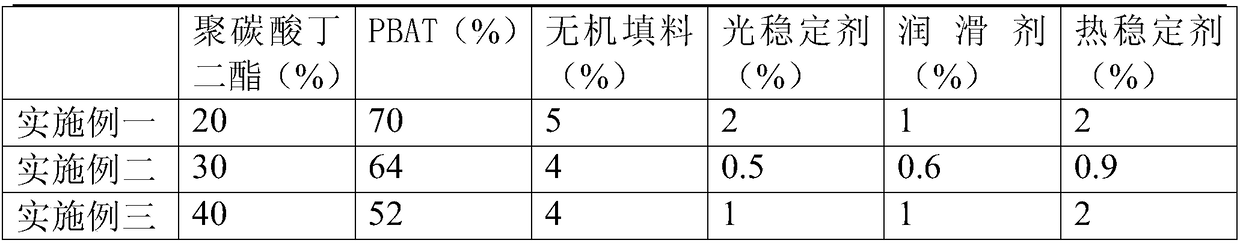

[0060] A high-barrier biodegradable mulch film is made of the following raw materials in the following weight percentages:

[0061]

[0062] Above-mentioned aliphatic polycarbonate is selected from a kind of in polybutylene carbonate, polypentamethylene carbonate, polyhexamethylene carbonate, polypropylene carbonate, poly(carbonic acid-terephthalic acid) butylene or its combination, and the molecular weight of aliphatic polycarbonate is 40,000-150,000. Embodiment one to embodiment three select polybutylene carbonate for use.

[0063] The above-mentioned inorganic filler is selected from titanium dioxide, talc powder, barium sulfate or a combination thereof, and the particle size of the inorganic filler is greater than 2000 mesh. The preferred inorganic filler in Embodiment 1 to Embodiment 3 is talc powder.

[0064] The above-mentioned light stabilizer is selected from hindered amine light stabilizers, one or a combination of ultraviolet absorbers; the above-mentioned ultra...

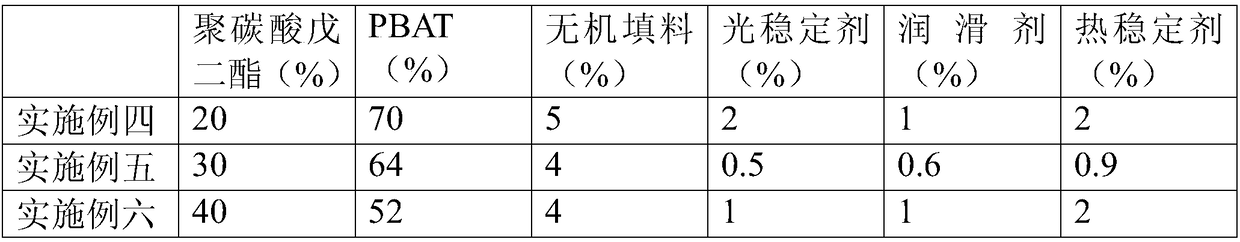

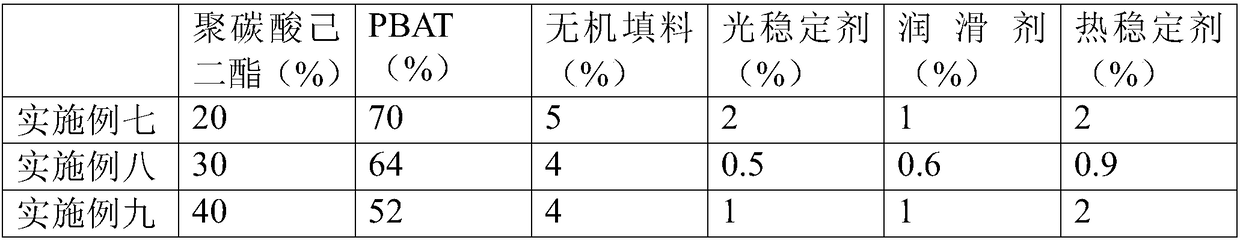

Embodiment 4 Embodiment 15

[0076]

[0077]

[0078]

[0079]

[0080] Compared with Example 1, Example 4 to Example 15 are only different in the high barrier biodegradable mulch film raw materials and their percentages, and the preparation methods and the selection of related auxiliary materials and auxiliary agents are consistent, so that Examples 4 to 10 are obtained. No. 5 high-barrier mulch products.

[0081] By testing the water vapor transmission rate of the mulching film products in the above twelve embodiments, it can be found that the water vapor transmission rate of the high-barrier biodegradable mulching film products in Examples 4 to 15 is significantly lower than the PBAT mulching film under the same thickness condition, At the same time, the water vapor transmission rate is significantly higher than that of PE plastic film, and its water vapor transmission rate is suitable for the growth needs of most economic crops, so that the economic crops are in a suitable humidity conditio...

Embodiment 16 Embodiment 18

[0083] A heat-retaining, moisturizing and high-transmittance biodegradable mulch film, comprising a main layer of a transparent mulch film and an anti-fog inner layer;

[0084] Wherein the transparent mulch main layer is made of the following components by weight percentage:

[0085]

[0086] The difference between Embodiment 16 and Embodiment 18 lies only in the proportion of fumed silica in the entire formula, and the proportion of fumed silica mainly affects the composite effect of the hydrophilic anti-fog coating and the main layer of the transparent mulching film.

[0087] The preparation of the main layer of the transparent mulch film includes the following steps: the raw materials are sequentially melt-blended, granulated and blown to obtain a main layer product of the biodegradable transparent mulch film;

[0088] a. After mixing the raw materials of the main layer of transparent mulching film evenly, put them into a twin-screw extruder for melt blending;

[0089] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com