Retarding water reducing agent used in high temperature construction environment

A slow-setting water-reducing agent and high-temperature construction technology, applied in the field of retarding water-reducing agents, can solve the problems of accelerating cement hydration speed, shortening cement setting time, hindering normal cement hydration, etc., achieving low addition, good economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

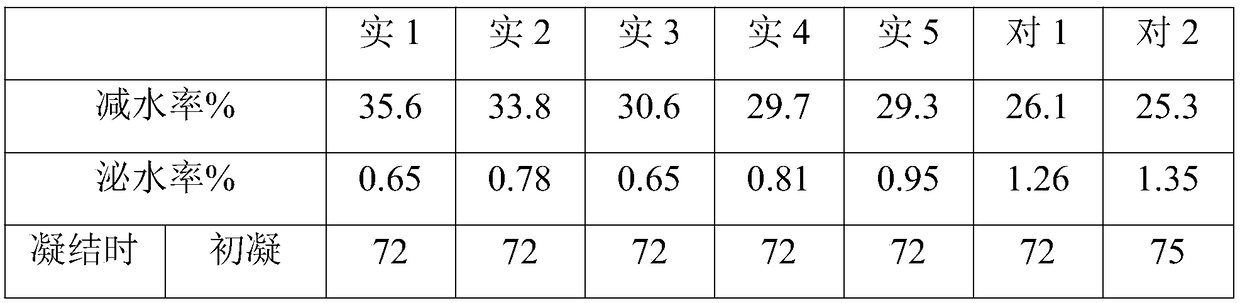

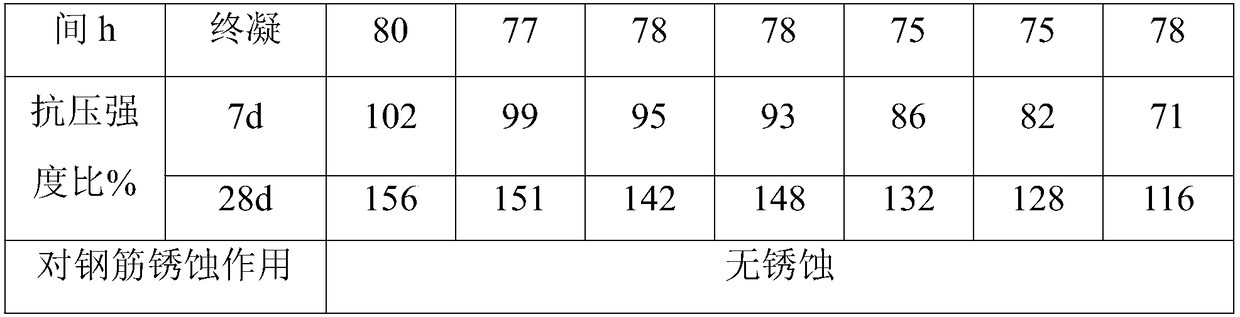

Examples

preparation example Construction

[0014] The present invention also provides a method for preparing the retarded water reducer used in high-temperature construction environments, comprising the following steps:

[0015] (1) Add sodium polyaspartate, p-aminobenzenesulfonic acid and isomeric tridecyl alcohol polyoxyethylene ether to polyaluminum chloride, heat to 115-125°C and mix for 0.5-1h, then place in 0- Put it in a sealed environment at 5°C for 1-2 hours, and make a fine powder through an ultrafine pulverizer to obtain modified polyaluminum chloride;

[0016] (2) Add kaolin, asbestos wool and modified polyaluminum chloride to the mixed solution of water and acetone, mix well, then add polycarboxylic acid mother liquor, sodium gluconate, methyl-β-cyclodextrin polyacrylamide Branch copolymer, ammonium citrate, anhydrous sodium sulfate and calcium chloride, mixed evenly to get retarded superplasticizer.

[0017] Under optimal conditions, the preparation method of the methyl-β-cyclodextrin polyacrylamide graf...

Embodiment 1

[0031] (1) Add 1g of sodium polyaspartate, 3g of p-aminobenzenesulfonic acid and 1g of isomeric tridecyl alcohol polyoxyethylene ether to 2g of polyaluminum chloride, heat to 120°C and mix for 1h, then place at 0°C Seal and stand in the environment for 1.5h, and make a fine powder with a particle size of 3-5 microns through an ultrafine pulverizer to obtain modified polyaluminum chloride;

[0032] (2) Add 8g kaolin, 2g asbestos wool and the above-mentioned modified polyaluminum chloride to the mixed solution of 40g water and 5g acetone, fully mix, then add 40g polyether polycarboxylic acid mother liquor (solid content is 55-75%) ), 6g of sodium gluconate, 4g of methyl-β-cyclodextrin polyacrylamide graft copolymer, 15g of ammonium citrate, 5g of anhydrous sodium sulfate and 3g of calcium chloride, mix well to get retarded superplasticizer .

[0033] Among them, the content of crystalline kaolinite in kaolin is higher than 80% by weight, quartz is lower than 0.5% by weight, Fe ...

Embodiment 2

[0036] (1) Add 0.5g sodium polyaspartate, 2g p-aminobenzenesulfonic acid and 0.5g isomeric tridecanol polyoxyethylene ether to 1g polyaluminum chloride, heat to 125°C and mix for 1h, then place Put it in a sealed environment at 0-5°C for 2 hours, and make a fine powder with a particle size of 3-5 microns through an ultrafine pulverizer to obtain modified polyaluminum chloride;

[0037] (2) Add 8g kaolin, 2g asbestos wool and modified polyaluminum chloride to the mixed solution of 55g water and 3g acetone, fully mix, then add 40g polyether polycarboxylate mother liquor (solid content is 55-75%) , 6g of sodium gluconate, 2g of methyl-β-cyclodextrin polyacrylamide graft copolymer, 12g of ammonium citrate, 8g of anhydrous sodium sulfate and 5g of calcium chloride, mixed evenly to obtain a retarded superplasticizer.

[0038] Among them, the content of crystalline kaolinite in kaolin is higher than 80% by weight, quartz is lower than 0.5% by weight, Fe 2 o 3 Less than 1.0% by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com