A kind of fragrance anti-fingerprint film and preparation method thereof

An anti-fingerprint film and anti-fingerprint technology, which is applied in the field of materials, can solve the problems of the appearance of electronic products, the film has no anti-fingerprint, and easy to leave fingerprints, etc., to achieve the effect of improving the retention period, improving adhesion, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

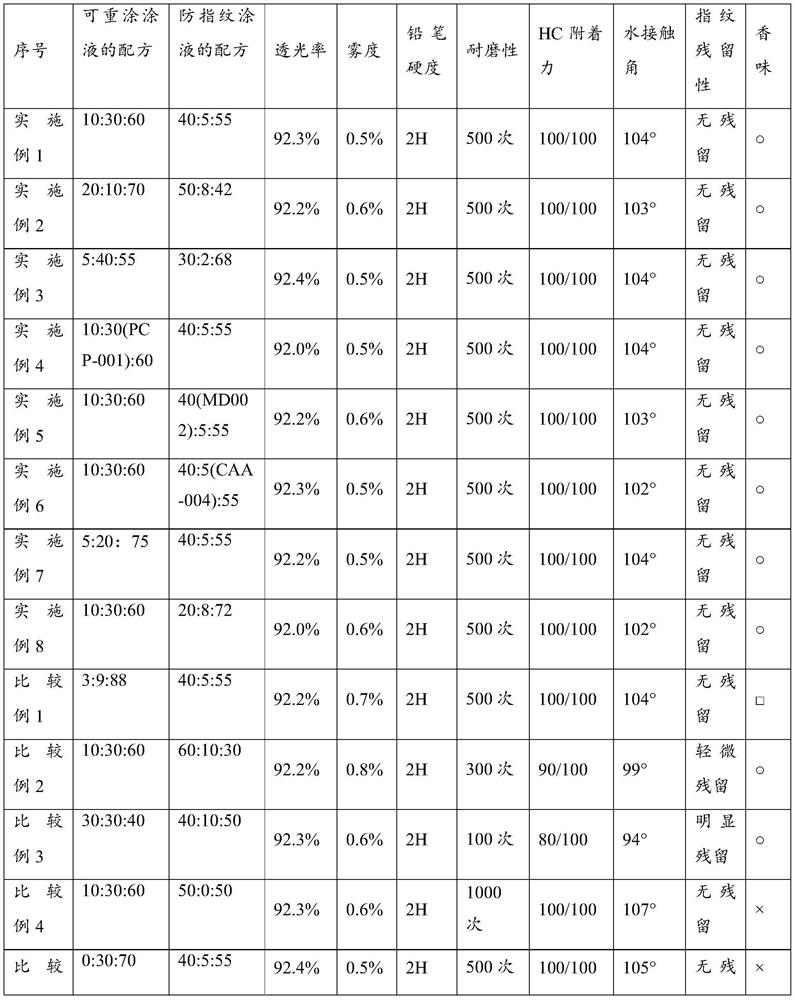

[0051] Recoatable coating liquid: dissolve 10 parts by weight of spices (rose fragrance, provided by Yilun Chemical) and 30 parts by weight of recoatable UV-curable resin MA003 (provided by Lida Chemical) into 60 parts by weight of butanone solvent In the middle, stir for 30 minutes to form a recoatable coating liquid;

[0052] Anti-fingerprint coating solution: dissolve 40 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical Industry) and 5 parts by weight of ADD-3275 curing agent (provided by Lida Chemical Industry) into 55 parts by weight of butanone and isopropyl In an alcohol (equal volume ratio) mixed solvent, stir for 30 minutes to form a pore-forming anti-fingerprint coating solution;

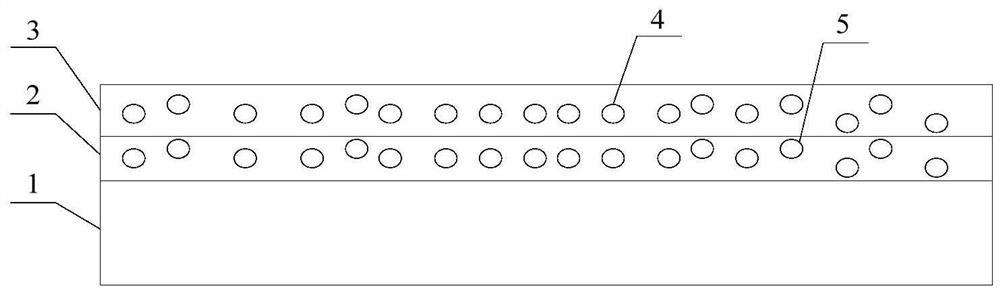

[0053] First, apply the recoatable coating liquid on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, and dry it in a circulating oven at 80°C for 2 minutes, and then pass a dose of about 400mJ / cm 2 UV irradiation to o...

Embodiment 2

[0055] Recoatable coating solution: dissolve 20 parts by weight of spices (rose fragrance, provided by Yilun Chemical) and 10 parts by weight of recoatable UV-curable resin MA003 (provided by Lida Chemical) into 70 parts by weight of butanone solvent In the middle, stir for 30 minutes to form a recoatable coating liquid;

[0056] Anti-fingerprint coating solution: dissolve 50 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical Industry) and 8 parts by weight of ADD-3275 curing agent (provided by Lida Chemical Industry) into 42 parts by weight of methyl ethyl ketone and isopropyl In an alcohol mixed solvent (equal volume ratio), stir for 30 minutes to form a pore-forming anti-fingerprint coating solution;

[0057] First, apply the recoatable coating liquid on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, and dry it in a circulating oven at 80°C for 2 minutes, and then pass a dose of about 400mJ / cm 2 UV lig...

Embodiment 3

[0059] Recoatable coating liquid: dissolve 5 parts by weight of spices (rose fragrance, provided by Yilun Chemical) and 40 parts by weight of recoatable UV-curable resin MA003 (provided by Lida Chemical) into 55 parts by weight of butanone solvent In the middle, stir for 30 minutes to form a recoatable coating liquid;

[0060] Anti-fingerprint coating solution: dissolve 30 parts by weight of anti-fingerprint UV-curable resin MA001 (provided by Lida Chemical Industry) and 2 parts by weight of ADD-3275 curing agent (provided by Lida Chemical Industry) into 68 parts by weight of butanone and isopropyl In an alcohol mixed solvent (equal volume ratio), stir for 30 minutes to form a pore-forming anti-fingerprint coating solution;

[0061] First, apply the recoatable coating liquid on a PET transparent substrate (Cologne U43R, South Korea) with a thickness of 100 μm, and dry it in a circulating oven at 80°C for 2 minutes, and then pass a dose of about 400mJ / cm 2 UV irradiation to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com