Tissue engineering cartilage framework as well as preparation method and application thereof

A tissue engineering and cartilage technology, applied in the fields of medicine and biomedical engineering, can solve the problems of insufficient mechanical strength of regenerated cartilage, damage to the structural integrity of cartilage acellular matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the tissue engineering cartilage scaffold provided by the invention comprises steps:

[0035] The first step is to perform laser drilling on the natural cartilage tissue to obtain microporous cartilage tissue. The output power in the drilling parameters is 3-20 watts, the pulse time is 10-30 milliseconds, and the spot diameter is 100-500 microns. The number of repetitions is 2-8 times; in the second step, the microporous cartilage tissue that has been drilled by the laser is subjected to decellularization.

[0036] In the above first step, the output power is preferably 8-12 watts, more preferably 10 watts.

[0037] In the first step above, the pulse time in the punching parameters is preferably 16-18 milliseconds, more preferably 17 milliseconds.

[0038] In the above first step, the spot diameter is preferably 250 microns.

[0039] In the first step above, it is preferable to repeat punching 3-5 times, more preferably 4 times.

[0040] In ...

Embodiment 1

[0065] Fabrication of laser-drilled decellularized tracheal scaffolds

[0066] 1. Obtaining Allogeneic Tracheal Tissue

[0067] New Zealand white rabbits were sacrificed with an air plug, and a 3-4 cm trachea was cut from the neck to expose the trachea and placed in phosphate buffered solution (PBS) at 4°C. Accompanying muscle and adipose tissue are carefully removed to obtain allogeneic tracheal tissue (still tubular, see figure 1 A) and placed in PBS at 4°C.

[0068] 2. Laser drilling the trachea and screening the optimal parameters

[0069] The trachea is supported by a support tube that is almost equal to the inner diameter of the trachea (or a little smaller), and then rotated at a certain rate, C0 2 A laser puncher (synrad-6500, WA98275)) emits a laser to punch a hole on the surface of the trachea ( figure 1 B). When the parameter is set to an output power below 5W, even if the pulse time and repetition times remain unchanged, the micropore depth may only reach 1 / 2 ...

Embodiment 2

[0089] In vivo / in vitro construction of tissue engineered tracheal cartilage grafts

[0090] 1. Isolation and Culture of Chondrocytes

[0091] The conventional method is to isolate chondrocytes from rabbit auricular cartilage and carry out in vitro expansion and culture to P2 generation.

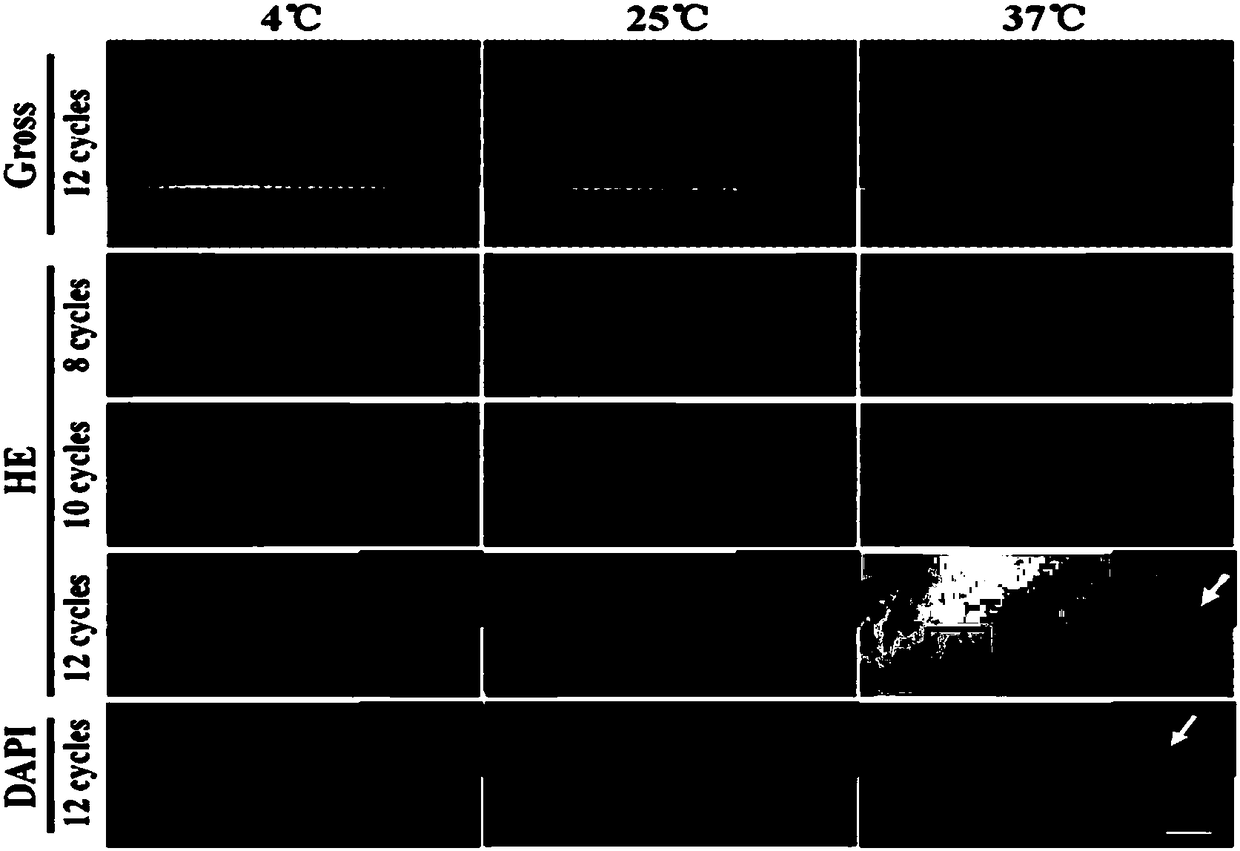

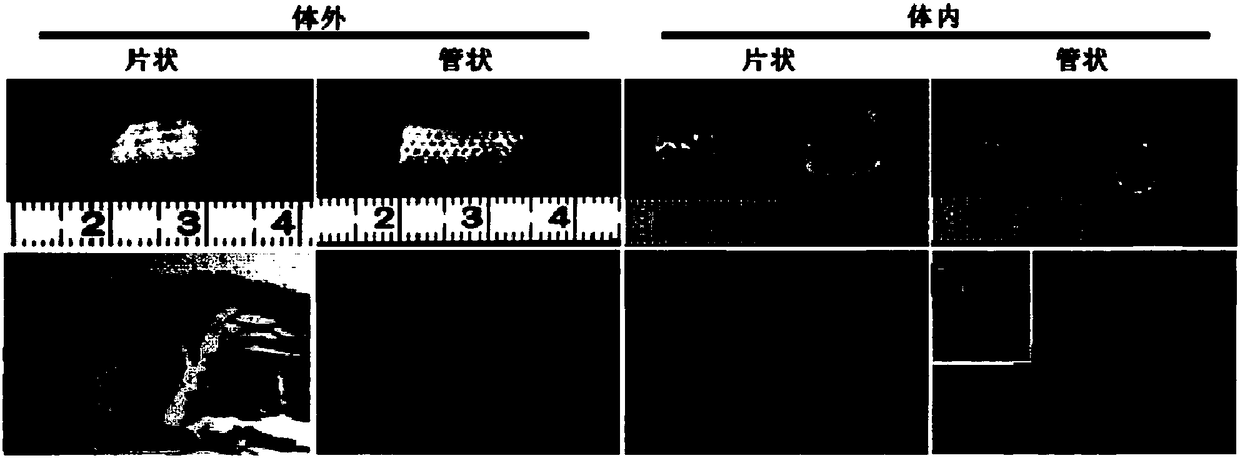

[0092] 2. In vivo and in vitro regeneration of tissue-engineered tracheal cartilage

[0093] Collect a sufficient amount of second-generation chondrocytes, carefully and evenly inoculate the cells on the outer surface of the acellular matrix scaffold (sheet and tube), culture at 37°C, 5% CO2, and saturated humidity conditions, and change the medium every 2 days. Two weeks later, some of the cell-material complexes were implanted into nude mice and cultured for 12 weeks; the rest of the cell-material complexes were cultured in vitro for up to 8 weeks. It was found that, no matter in vivo or in vitro, tissue engineered cartilage tissue with porcelain white and sufficient mechanical strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com