Nanosphere-metal composite catalyst, preparation method thereof, application and preparation method of 5-hydroxyl-1-tetralone

A nano-microsphere and metal composite technology, applied in the preparation of 5-hydroxy-1-tetralone, nano-microsphere-metal composite catalyst and its preparation field, can solve the problem of difficult synthesis, poor selectivity, no mention and other problems, to achieve the effect of easy regeneration, reducing the loss of raw materials and energy, and regular and orderly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides the preparation method of nano microsphere-metal composite catalyst described in the above scheme, comprising the following steps:

[0030] SiO 2 The nanospheres were soaked in the palladium salt solution to obtain the soaked SiO 2 Palladium salt solution of nano-microspheres;

[0031] will be soaked with SiO 2 The palladium salt solution of the nanospheres was heated to dryness to obtain SiO 2 Nano microsphere-palladium salt complex;

[0032] The SiO 2 The nanometer microsphere-palladium salt complex is reduced by hydrogen to obtain the nanometer microsphere-metal composite catalyst.

[0033] In the present invention, SiO 2 The nanospheres were soaked in the palladium salt solution to obtain the soaked SiO 2 Palladium Salt Solution of Nanospheres. The present invention to the SiO 2 There is no special requirement for the source of the nanospheres, and they can be prepared using methods well known to those skilled in the art. In s...

Embodiment 1

[0054] SiO 2 Preparation of nanosphere seeds:

[0055] Weigh 0.1756g of arginine into a 250mL round bottom flask, add 170.05g of deionized water, stir to dissolve, add 10.4139g of tetraethyl silicate, raise the temperature to 70°C, keep the speed at 460rpm, and put a stopper on the top of the flask , stirred in an oil bath at 70°C for 24 hours. After the reaction, it was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner of 1000 mL, and heated in an oven at 100°C for 20 hours. Then transfer it to a crystallization dish and put it in an oven to dry at 100°C. After drying, put it into a muffle furnace and bake it at 600°C for 4 hours to obtain SiO 2 Nano-microsphere seeds, the product is in the form of translucent filaments.

[0056] 200nm SiO 2 Preparation of microspheres:

[0057] Weigh 41.4 g of deionized water into a 250 mL round bottom flask, add 0.1360 g of seed solution, 133.6 g of ethanol, and 0.2613 g of arginine, stir and dissolve at room te...

Embodiment 2

[0065] (1) 5%Pd / SiO 2 Preparation of 200nm microsphere catalyst:

[0066] Take by weighing the 200 nanometers of SiO that embodiment 1 prepares 2 2.0 grams of nanospheres, add 10 grams containing 167 mg of PdCl 2 solution, after soaking for 0.5h, the mixture was heated and stirred until dry, and the obtained SiO 2 The nanosphere-palladium salt complex was cooled to room temperature, and finally the dried SiO 2 The nanosphere-palladium salt complex was reduced by hydrogen at 350°C for 4 hours to prepare a nanosphere-metal composite catalyst with a Pd loading of 5% (5%Pd / SiO 2 200 nm microsphere catalyst).

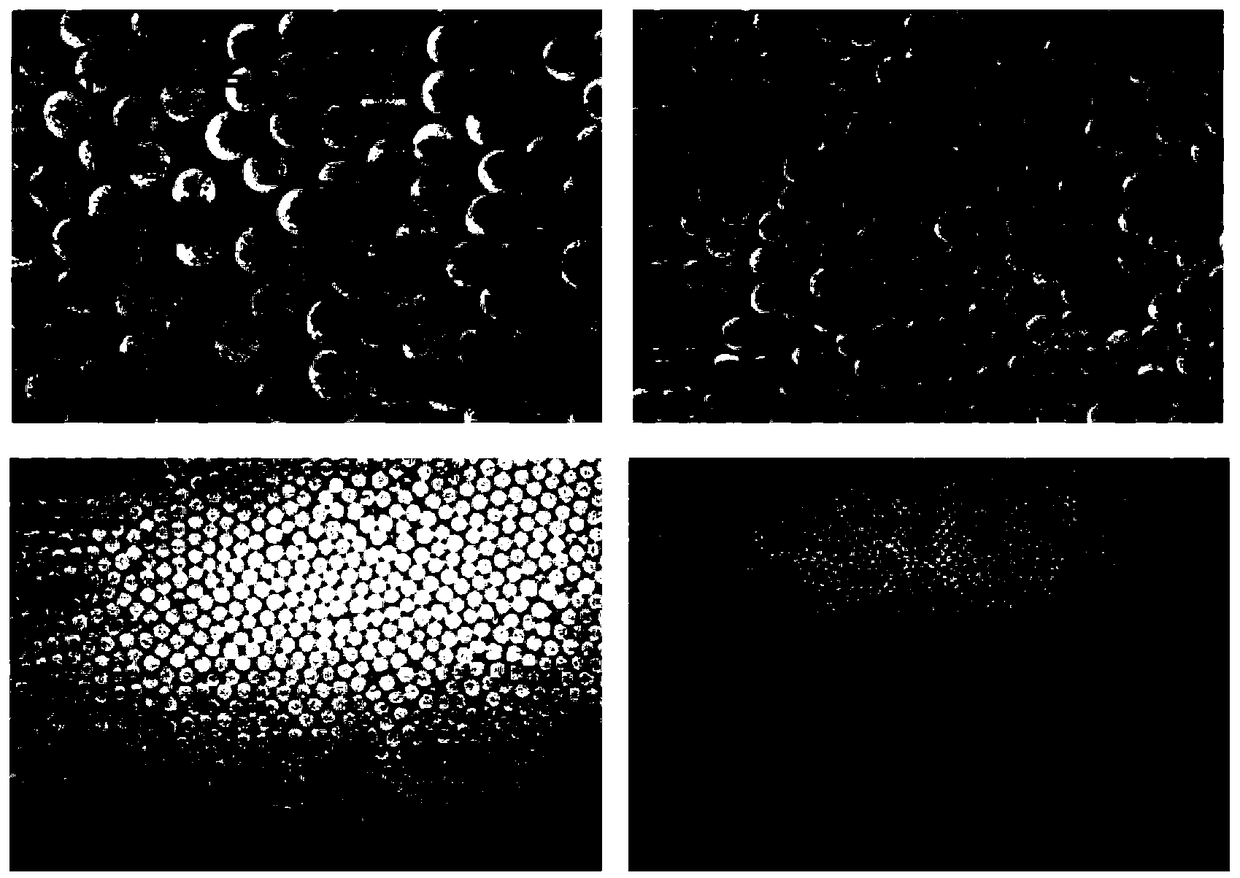

[0067] 200 nm SiO using SEM 2 Nanospheres were observed, and the results were as follows figure 1 shown, according to figure 1 It can be seen that the obtained SiO 2 The nano-microspheres have a uniform particle size and are in the form of white flakes.

[0068] The obtained 5%Pd / SiO 2 200 nanometer microsphere catalyst was observed, and the obtained results are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com