Titanium dioxide/polyaniline nano-composite structure and preparation method thereof

A titanium dioxide and nano-composite technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of no utilization rate of visible light and affect large-scale applications, etc., achieve low cost, stable product quality, and cheap raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

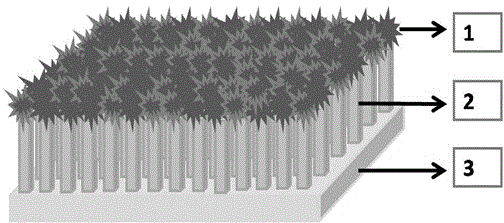

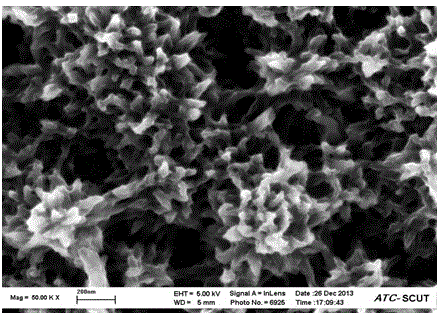

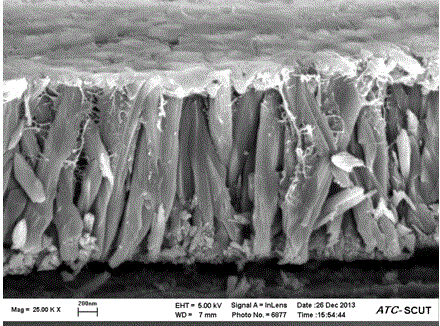

[0025] Example 1 ~8: The preparation steps of titanium dioxide polyaniline composite nanostructure are:

[0026] (1) Prepare reaction solution A with butyl titanate, concentrated hydrochloric acid, and distilled water in a certain volume ratio, and place reaction solution A in a 100mL sealed high-pressure reactor. Place the FTO conductive glass in acetone, absolute ethanol and distilled water for 30 minutes, and then dry it and place it in the above reaction solution A, with the FTO conductive side facing down, and control the reaction temperature and reaction time. After the reaction is completed, The product is taken out, washed 2 to 3 times with distilled water, and dried at room temperature to obtain the product titanium dioxide nanorod array.

[0027] (2) Prepare dilute hydrochloric acid solution B of aniline by mixing aniline monomer solution and 1mol / L dilute hydrochloric acid solution according to a certain volume ratio; place the titanium dioxide nanorod array pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com