Heating thermal-insulating riser used for nodular cast iron, and preparation method thereof

A heat preservation riser and nodular cast iron technology, which is applied to casting molding equipment, casting molds, and casting mold components, can solve problems such as high raw material costs, insufficient heat generation, and inappropriate composition ratios, and achieve stable chemical properties and easy sources Acquisition, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method for preparing a heat-insulating riser for ductile iron, comprising the steps of:

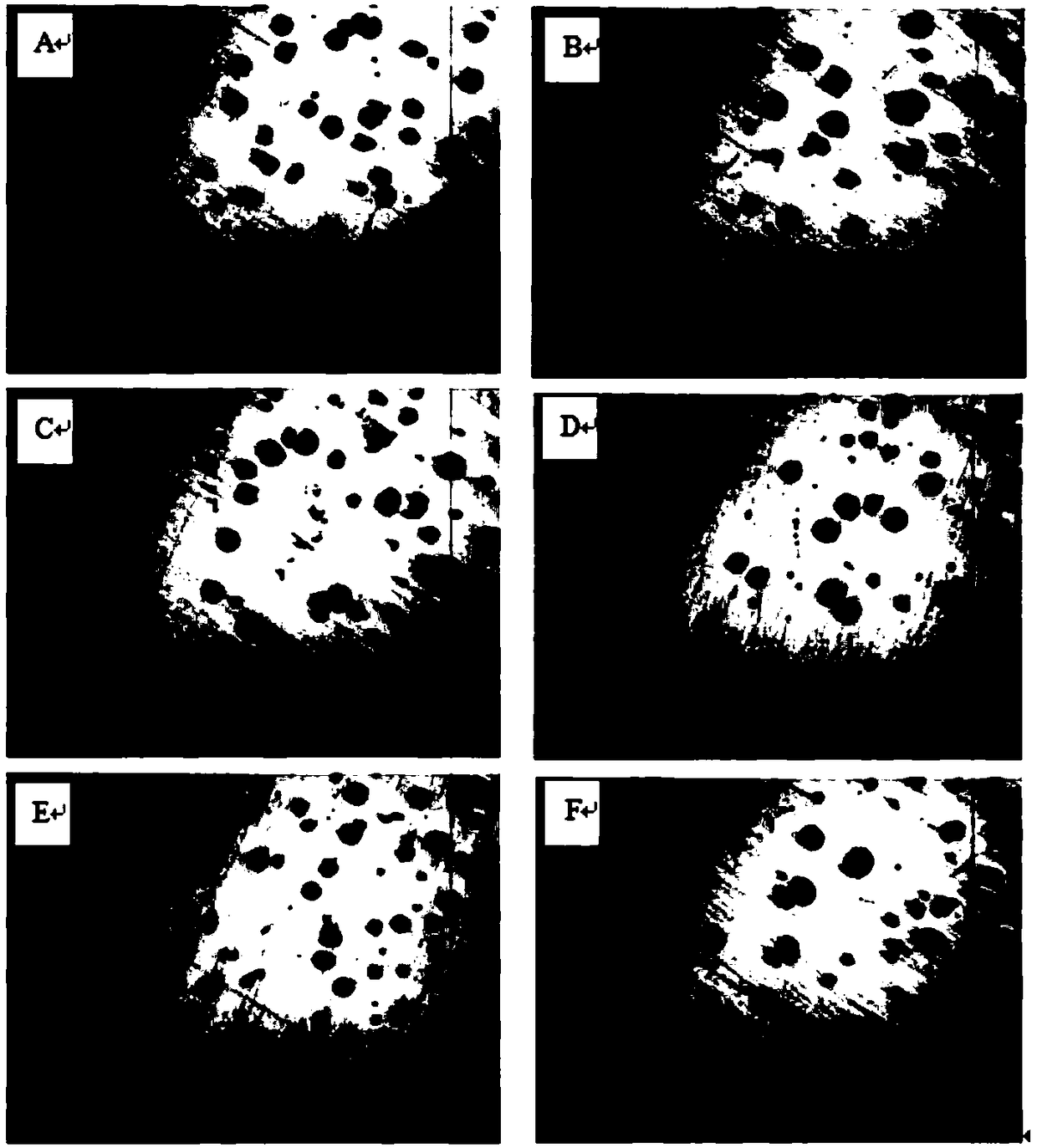

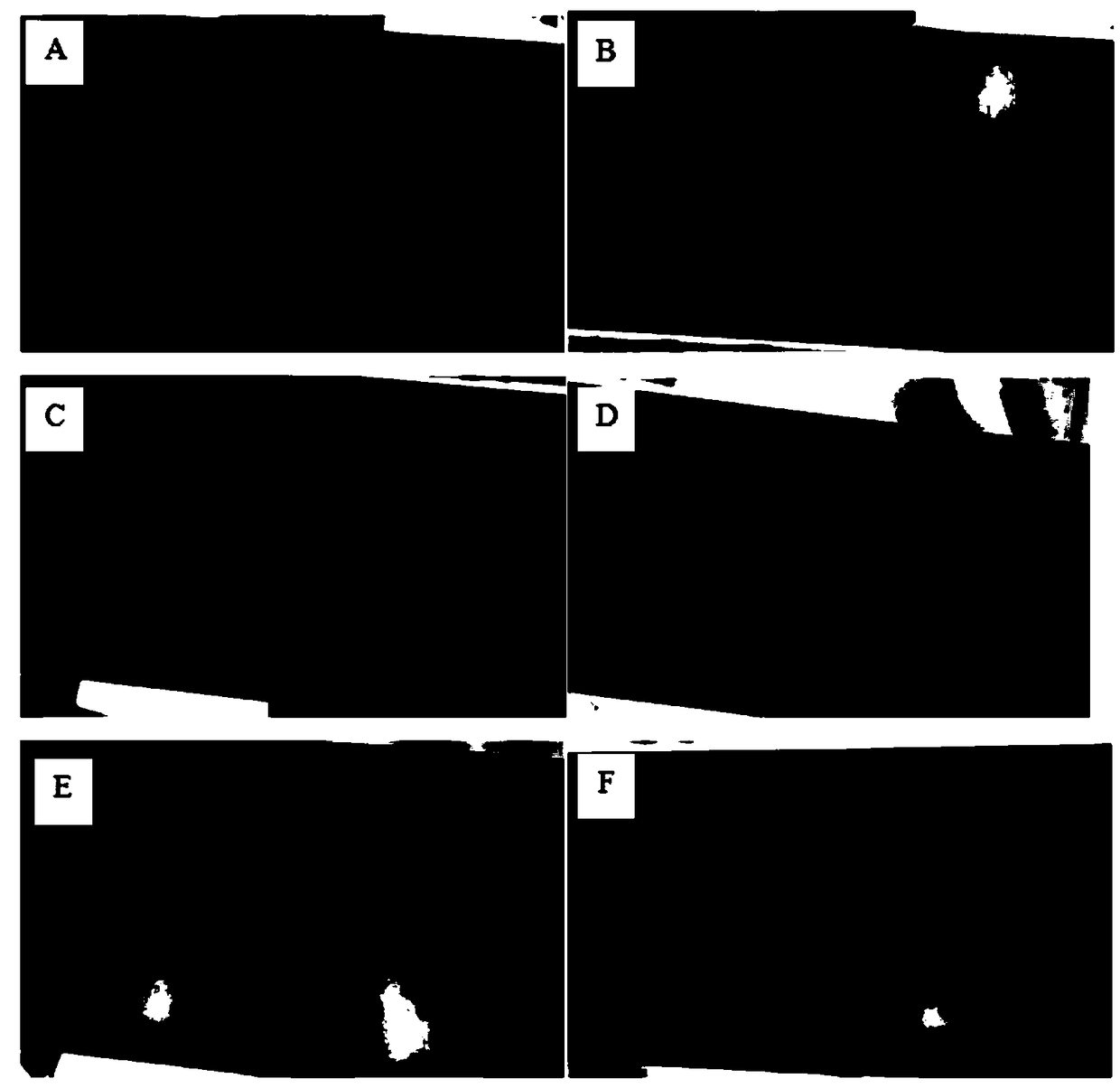

[0062] (1) each raw material is crushed and then dried, and then each raw material is weighed according to the proportion of component A, then mixed with component B evenly, bonded, placed in a mold to form, and the riser blank is obtained; said A, The specific content of component B is shown in Table 3, which are respectively recorded as groups A-F. The bottom plate is 180mm long, 140mm wide, and the symmetrical pin spacing is 122mm; the long side of the central elliptical cylinder is 77mm, and the short side is 52.5mm; the two petals are 142mm long and 74mm wide.

[0063] In step (1), the method of described mixing is:

[0064] 1) First, the water glass with a Baume degree of 50° is diluted to 50%, and the water glass is equally divided into two parts for later use;

[0065] 2) Mix the floating beads with a portion of water glass diluted in step (1), so that the surface of th...

Embodiment 2

[0078] A method for preparing a heating and heat preservation riser for ductile iron, the same as in Example 1, the difference is that in step (1), by mass percentage, the A component is composed of the following components: 20% aluminum powder, graphite powder 14.5%, iron oxide powder 6%, potassium salt 4%, manganese dioxide 0.5%, floating beads 45%, sodium fluoroaluminate 5%, silica sand 5%; the B component is water glass, the water glass The content is 17% of the total weight of component A. In step (2), carbon dioxide gas is introduced to self-harden the formed riser blank.

Embodiment 3

[0080] A method for preparing a heating and heat preservation riser for ductile iron, the same as in Example 1, the difference is that in step (1), by mass percentage, the A component is composed of the following components: 20% aluminum powder, graphite powder 14.5%, iron oxide powder 12%, potassium salt 8%, manganese dioxide 0.5%, floating beads 40%, sodium fluoroaluminate 3%, silica sand 2%; the B component is water glass, the water glass The content is 14% of the total weight of component A. The drying time in step (2) is 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com