A kind of thermoplastic polyester elastomer and its preparation and application

A thermoplastic polyester and elastomer technology, applied in the field of materials, can solve the problems of carbon emission, environmental pollution, environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a kind of preparation method of described thermoplastic polyester elastomer, described method comprises the steps:

[0065] 1) The first mixture, esterification catalyst, polycondensation catalyst and auxiliary agent are provided, wherein, the first mixture comprises the following components: component (a) furandicarboxylic acid and / or its esterified product, component (b) fat Family dibasic acid and / or its esterification product and component (c) glycol;

[0066] 2) In the reactor, mixing the first mixture and the esterification catalyst to obtain a second mixture;

[0067] 3) under stirring conditions, heating the second mixture to the first reaction temperature, and reacting for the first period of time to obtain the third mixture;

[0068] 4) mixing the third mixture, the polycondensation catalyst and the auxiliary agent to obtain a fourth mixture;

[0069] 5) heating the fourth mixture to a second reaction temperature and react...

Embodiment 1

[0089] Example 1 Thermoplastic polyester elastomer 1 (the molar content of 2,5-furandicarboxylic acid is 40%, R2 is C12 alkyl)

[0090]

[0091] Add 0.08mol of 2,5-furandicarboxylic acid, 0.12mol of dodecanedioic acid, 0.30mol of ethylene glycol, and 0.0004mol of anhydrous zinc acetate into a 1000mL reactor, vacuumize and replace with nitrogen three times, Start stirring, gradually raise the temperature to 180°C, and react for 4 hours. Add antimony trioxide, triphenyl phosphate and antioxidant to the system, raise the temperature to 230°C, and control the vacuum degree below 200Pa to react for 3 hours to obtain polyethylene 2,5-furandicarboxylate copolyester, which is a thermoplastic polymer. Ester Elastomer 1.

[0092] result

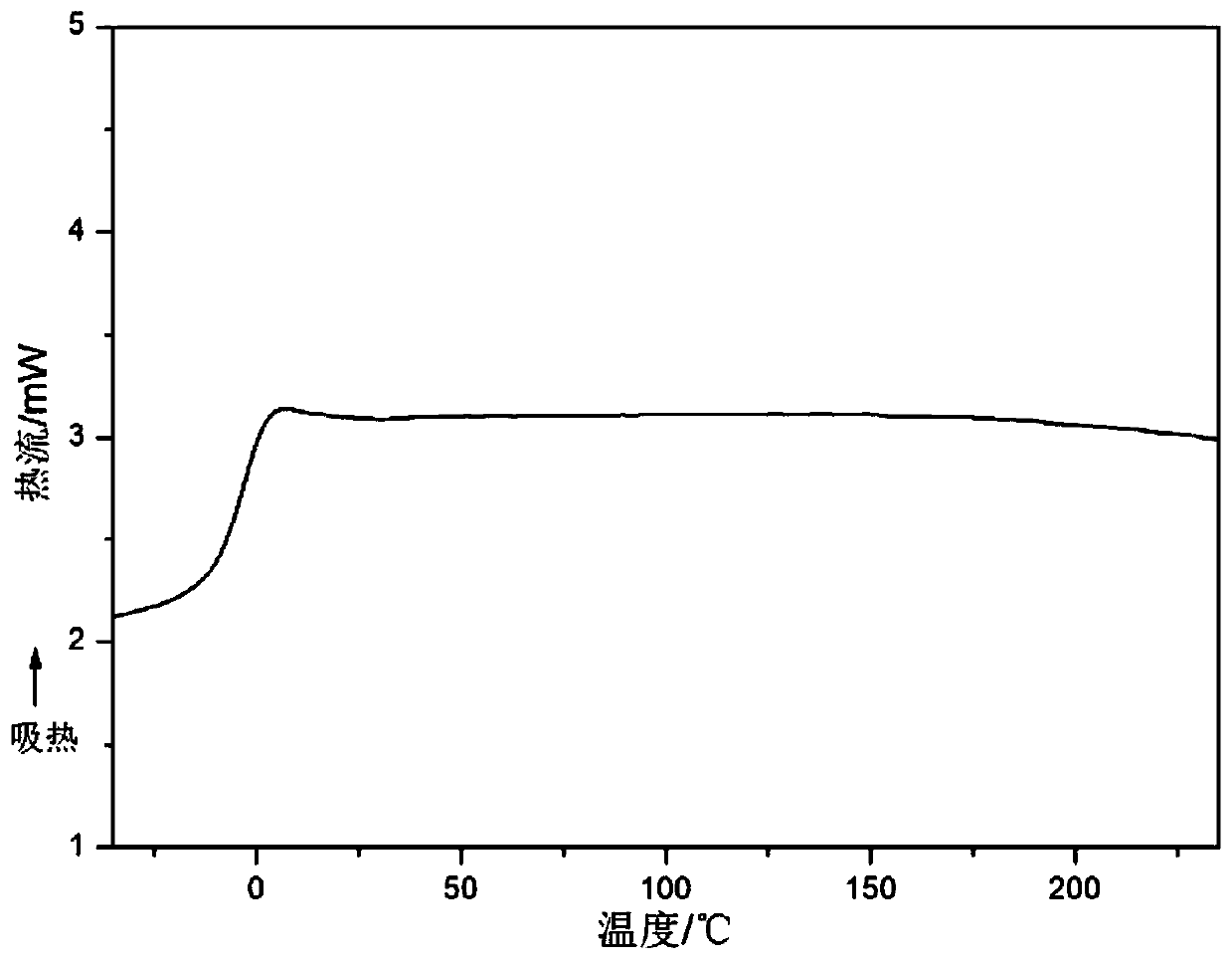

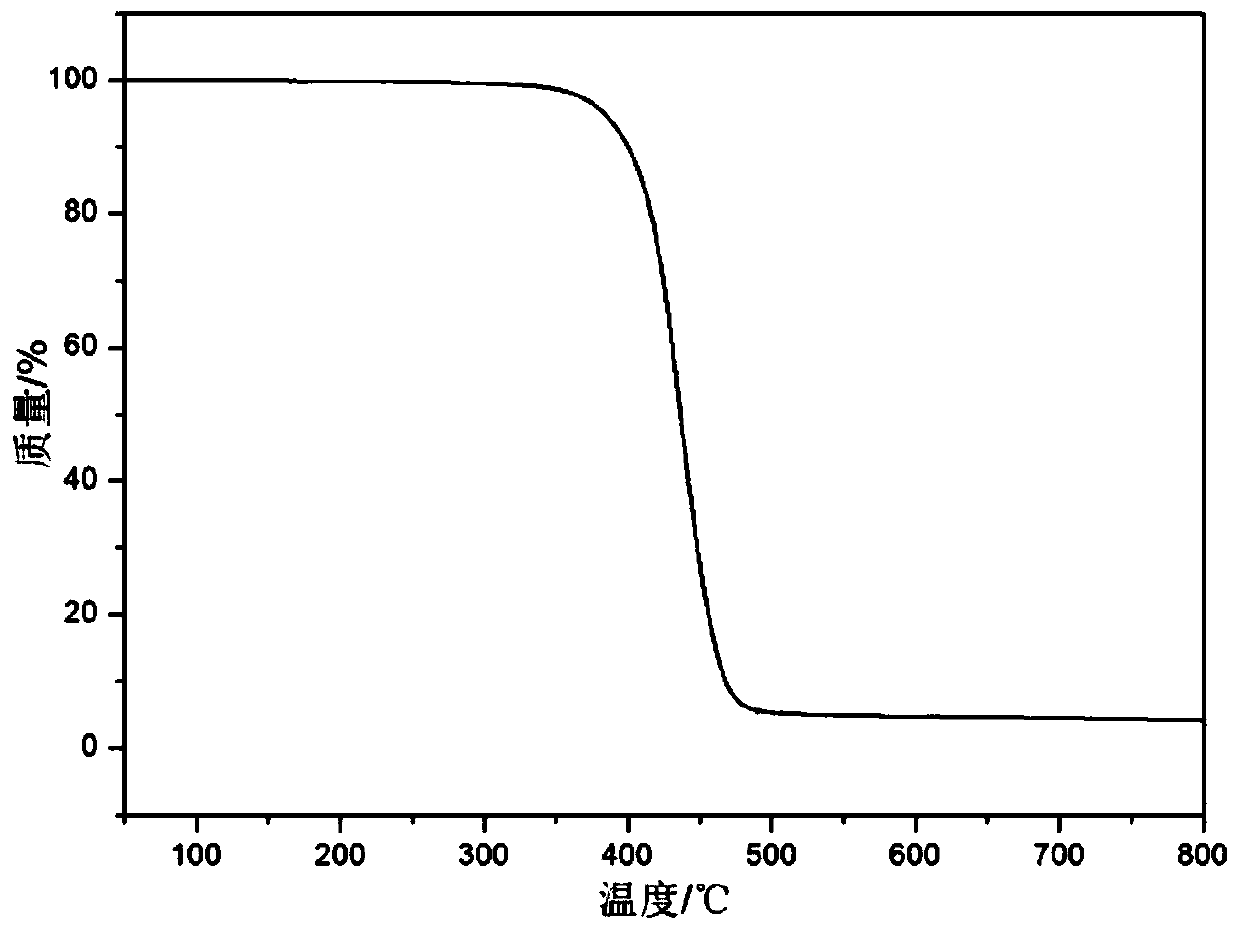

[0093] NMR, DSC, TGA, mechanical properties and other tests were carried out on the thermoplastic polyester elastomer 1 respectively.

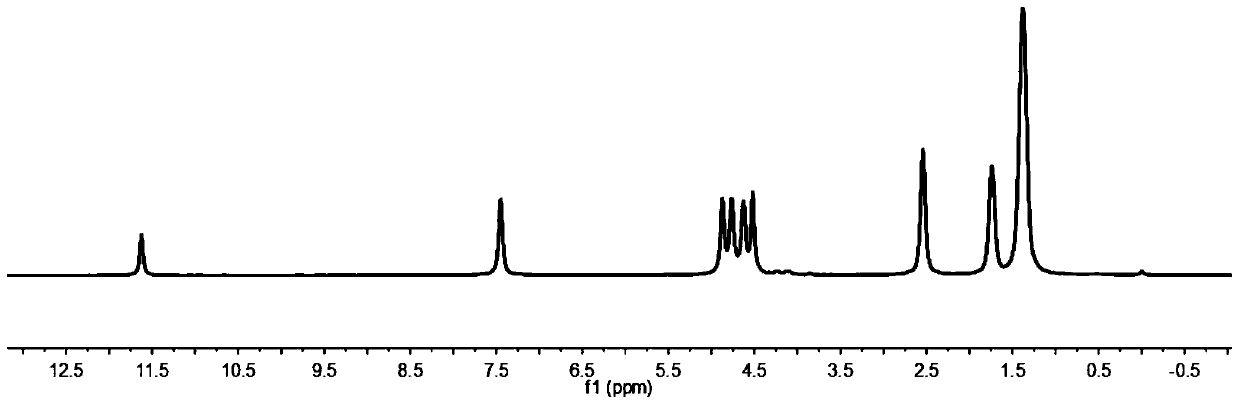

[0094] figure 1 for the thermoplastic polyester elastomer 1 1 H-NMR diagram.

[0095] From figure 1 It can...

Embodiment 2

[0107] Example 2 Thermoplastic polyester elastomer 2 (the molar content of 2,5-furandicarboxylic acid is 60%, R2 is C12 alkyl)

[0108] Same as Example 1, the difference is that the amount of 2,5-furandicarboxylic acid is 0.12 mol, and the amount of dodecanedioic acid is 0.08 mol.

[0109] After testing, the thermoplastic polyester elastomer 2 has a spline tensile strength of 20 MPa, a tensile modulus of 178 MPa, an elongation at break of 892%, a 500% elastic recovery rate of 87%, and an intrinsic viscosity of 1.2 dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com