Preparation method of crosslinking modified straw fiber/PP (polypropylene) wood-plastic composite material and obtained product

A wood-plastic composite material and straw fiber technology, which is applied in the field of preparation of PP wood-plastic composite materials, can solve problems such as poor environmental protection and water pollution, and achieve the effects of good environmental protection, good application prospects, and excellent mechanical properties and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

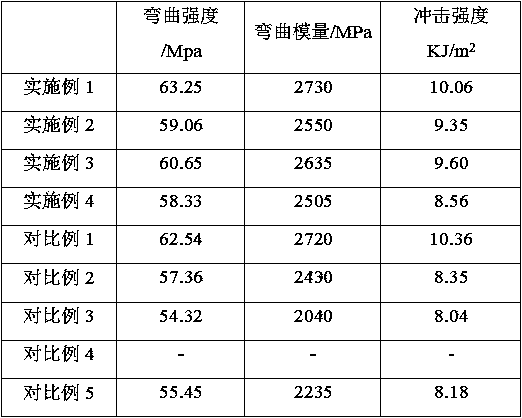

Examples

Embodiment 1

[0033] Prepare the wood-plastic composite material according to the following method, and the steps are as follows:

[0034] 1) Cross-linking modification of straw fiber

[0035] a. Dry the corn stalks in an air-blast drying oven at 80°C for 24 hours, peel off the corn stalks to obtain the husks, pulverize the stalks with an ultra-fine pulverizer, and pass through a 100-mesh standard sieve to obtain straw powder;

[0036] b. Dissolve 0.8g of chitosan in 40mL of acetic acid aqueous solution with a mass concentration of 2wt.%, and ultrasonically disperse until a uniform transparent jelly is formed;

[0037]c. Add 4g of KH560 dropwise into 400mL of 90wt% ethanol aqueous solution, and stir for 30min to obtain a hydrolyzate;

[0038] d. Add 20g of liquid paraffin, 1g of sodium dodecylbenzenesulfonate and 5g of straw powder to the jelly in step b, heat up to 60°C, and stir for 40min;

[0039] e. Add the KH560 hydrolyzate in step c to step d, adjust the pH to 7, and stir at 40°...

Embodiment 2

[0045] Prepare the wood-plastic composite material according to the following method, and the steps are as follows:

[0046] 1) Cross-linking modification of straw fiber

[0047] a. Dry the wheat straw in an air-blast drying oven at 80°C for 24 hours, pulverize the straw through an ultrafine grinder, and pass through a 100-mesh standard sieve to obtain straw powder;

[0048] b. Dissolve 0.5g of chitosan in 40mL of acetic acid aqueous solution with a mass concentration of 2wt.%, and ultrasonically disperse until a uniform transparent jelly is formed;

[0049] c. Add 2g of KH560 dropwise into 100mL of 80wt% ethanol aqueous solution and stir for 40min to obtain a hydrolyzate;

[0050] d. Add 10g of liquid paraffin, 0.5g of sodium dodecylbenzenesulfonate and 5g of straw powder to the jelly in step b, heat up to 65°C, and stir for 40min;

[0051] e. Add the KH560 hydrolyzate in step c to step d, adjust the pH to 8, and stir at 50°C for 2 hours to obtain a uniformly dispersed ...

Embodiment 3

[0057] Prepare the wood-plastic composite material according to the following method, and the steps are as follows:

[0058] 1) Cross-linking modification of straw fiber

[0059] a. Dry the rice straw in an air-blast drying oven at 80°C for 24 hours, pulverize the straw through an ultrafine grinder, and pass through a 100-mesh standard sieve to obtain straw powder;

[0060] b. Dissolve 0.5g of chitosan in 40mL of acetic acid aqueous solution with a mass concentration of 1wt.%, and ultrasonically disperse until a uniform transparent jelly is formed;

[0061] c. Add 3g of KH560 dropwise into 200mL of 85wt% ethanol aqueous solution, and stir for 30min to obtain a hydrolyzate;

[0062] d. Add 30g of liquid paraffin, 1g of sodium dodecylbenzenesulfonate and 5g of straw powder to the jelly in step b, heat up to 60°C, and stir for 40min;

[0063] e. Add the KH560 hydrolyzate in step c to step d, adjust the pH to 10, and stir at 40°C for 3 hours to obtain a uniformly dispersed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com