Preparation method of electrostatic spinning lithium ion battery negative electrode plate

A technology for lithium-ion batteries and negative pole pieces, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as low production efficiency, achieve low production costs, increase transmission rate, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

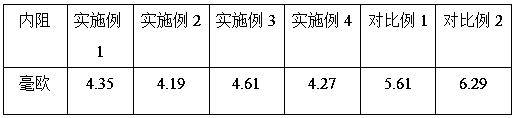

Examples

Embodiment 1

[0021] A method for preparing an electrospinning lithium-ion battery negative pole piece, comprising the steps of:

[0022] (1) lithium polyoxometalates Li 3 PMo 12 o 40 Dissolved in deionized water to form lithium polyoxometalate salt solution;

[0023] (2) graphite is added in lithium polyoxometalate solution, and surfactant sodium dodecylbenzenesulfonate is added to form a spinning solution; water-based adhesive LA13x is: acrylonitrile multi-polymer, respectively Any one of LA132, LA133 and LA135.

[0024] (3) Put the spinning solution into the electrospinning apparatus for spinning, the receiving plate is copper foil, the spinnerets are in multiple groups, and the distance between the spinneret and the receiving plate is 0.1-8cm (the best distance is 5cm) ;The voltage is 16-20KV (the best is 18Kv); the jet flow rate is 0.1-0.3mL / S (the best flow rate is 0.2mL / S), the filaments are densely and uniformly bonded to the copper foil, and then the bonding The copper foil wi...

Embodiment 2

[0028] Preparation method and test method are the same as embodiment 1, just change lithium polyoxometalate into Li 3 PW 12 o 40 .

Embodiment 3

[0030] Preparation method and test method are the same as embodiment 1, just change lithium polyoxometalate into Li 4 SiMo 12 o 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com