Lamellar silicon oxide and carbon and cobalt oxide composite material and preparation method thereof

A technology of silicon oxide and cobalt monoxide, which is applied in the field of preparation of silicon-based nanocomposite materials, can solve the problems of difficulty in realizing industrialized production, affecting the performance of electrode materials, unstable material structure, etc., and achieves low cost and short preparation period. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to a non-limiting embodiment of the present invention, a method for preparing a sheet-like silicon oxide and carbon-cobalt monoxide composite material is provided, the method comprising the following steps.

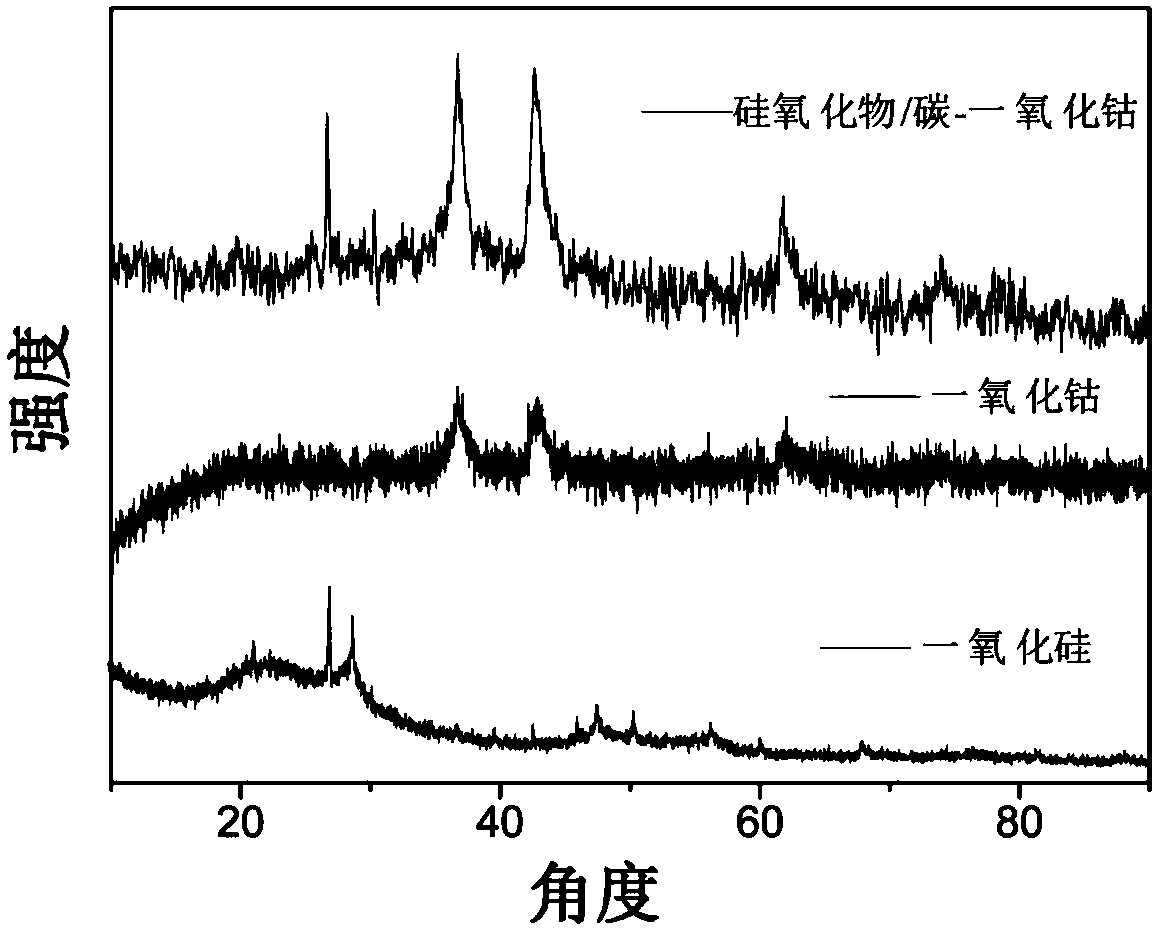

[0041] (1) Add silicon monoxide and graphite powder with a mass ratio of 0.1 to 0.5:1 into a ball mill jar, vacuum seal, place the ball mill jar in a high-energy ball mill, and mill for 15 to 28 hours to obtain a uniform and stable suspension. The suspension was dried in vacuo to obtain silicon oxide / carbon nanoparticles.

[0042] (2) Disperse the cobalt nitrate hexahydrate particles into the solvent to form a cobalt nitrate hexahydrate solution, disperse the silicon oxide / carbon nanoparticles prepared in step (1) into the cobalt nitrate hexahydrate solution, and stir magnetically at a constant temperature for 4-8 A suspension is formed within hours, wherein the mass ratio of cobalt nitrate hexahydrate particles to the solvent is 1:15-100, the solvent inc...

Embodiment 1

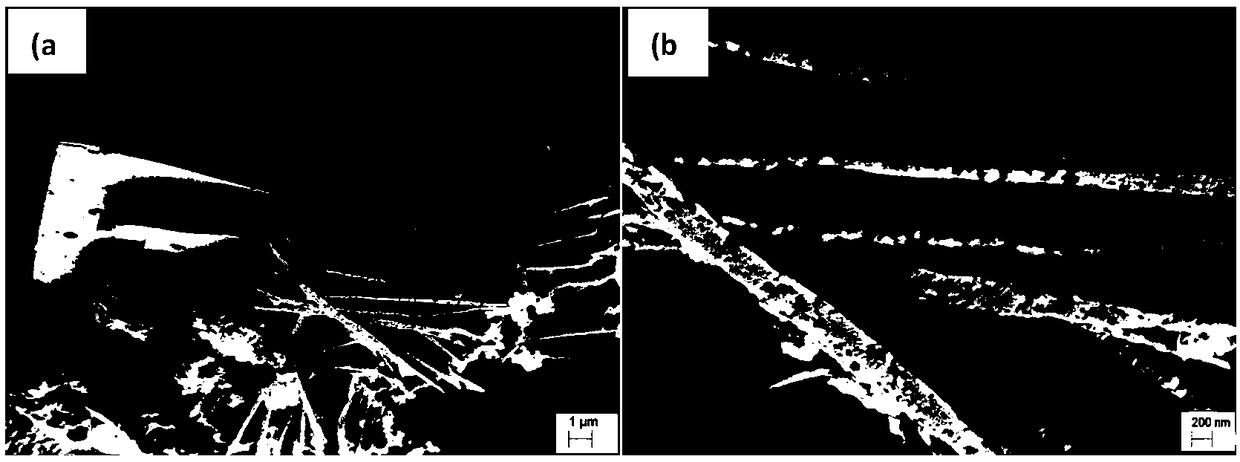

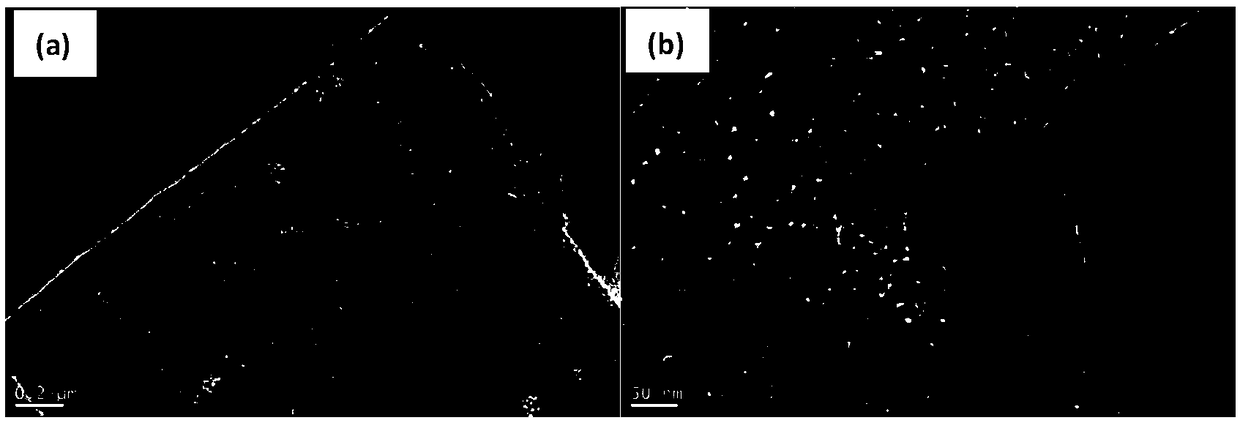

[0048] First, weighing silicon monoxide and graphite powder with a mass ratio of 0.1:1 is placed in an agate ball mill jar, wherein the mass ratio of the ball mill beads to the added substance is 20:1, and 20 milliliters of ethanol is added in the ball mill jar for Provide a liquid environment to make the ball mill more fully. Transfer the ball ink tank to a vacuum glove box for storage to provide vacuum conditions. After the sealing is completed, put it into the ball mill and mill it for 15 hours. Pour out the suspension obtained from the ball mill from the ball mill tank , placed in a petri dish, and the suspension was placed in a vacuum drying oven, and dried in vacuum at 60 degrees Celsius for 10 hours to obtain silicon oxide / carbon nanoparticles.

[0049] Next, disperse the prepared silicon oxide / carbon nanocomposite into the cobalt nitrate hexahydrate solution added with urea and cetyltrimethylammonium chloride, and then ultrasonically clean the mixture for 40 minutes, fo...

Embodiment 2

[0054] Except in step 1, ball milling time is 20 hours, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap