Preparation method of molybdenum disulfide/titanium carbide composite material

A composite material, molybdenum disulfide technology, applied in the field of materials, can solve the problems of insignificant improvement in electrochemical performance, high reaction temperature, and few active sites, and achieve excellent electrochemical performance, mild reaction conditions, and repeatability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.6 grams of sodium molybdate, 1 gram of thiourea, 0.33 grams of titanium carbide, and 45 mL of deionized water into a stainless steel reactor with a volume of 75 ml, stir for 30 minutes, seal it, and fill it with 60%; Put it in a crucible boiler, heat it at 200°C for 24 hours, then wait for the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was successively washed 6 times with absolute ethanol, dilute hydrochloric acid and distilled water, filtered, and then vacuum-dried at 60°C for 12 hours to obtain a molybdenum disulfide / titanium carbide composite material with excellent electrochemical properties.

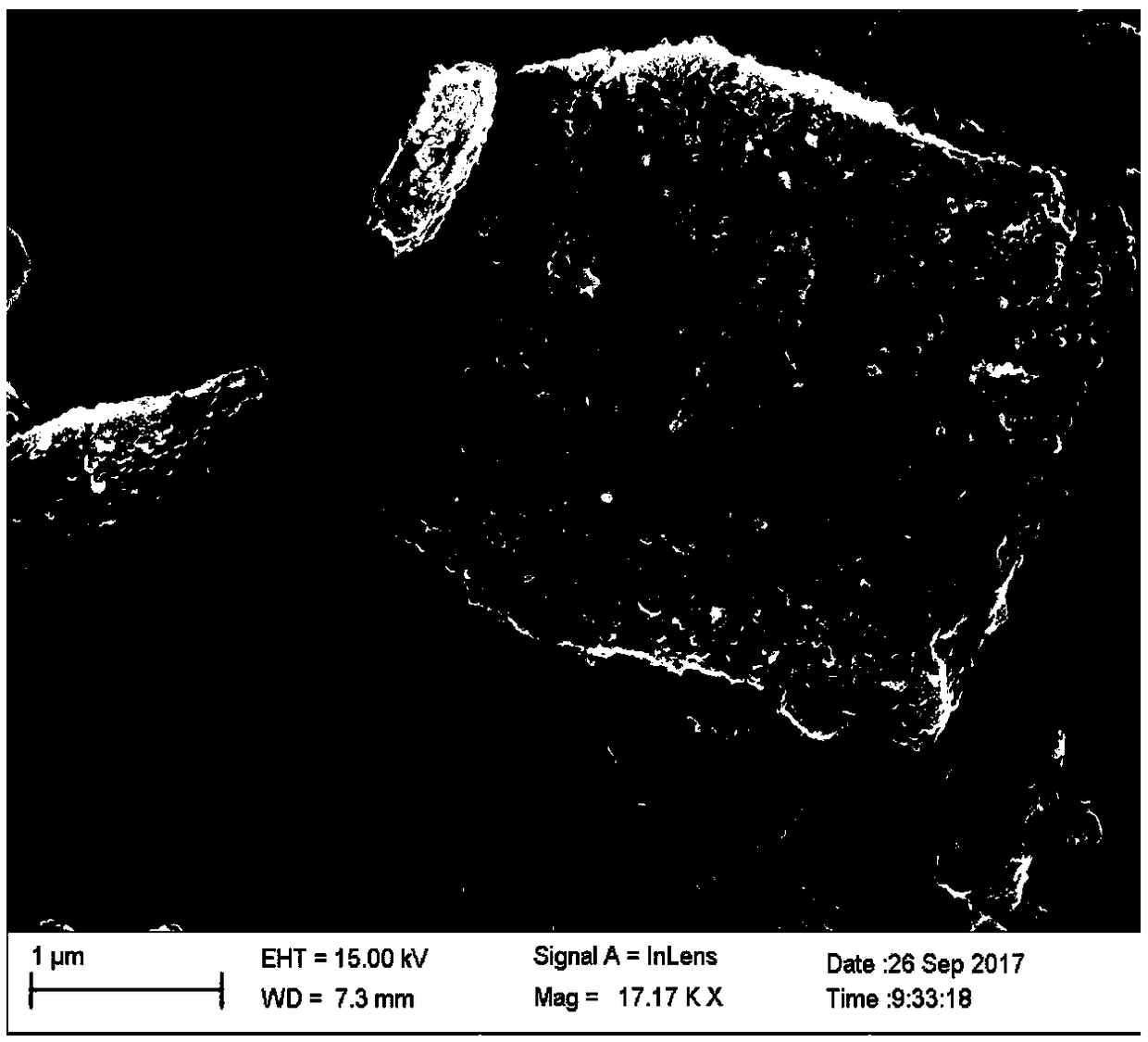

[0024] Such as figure 1 As shown, it can be clearly seen that the petal-shaped molybdenum disulfide and titanium carbide are composited together.

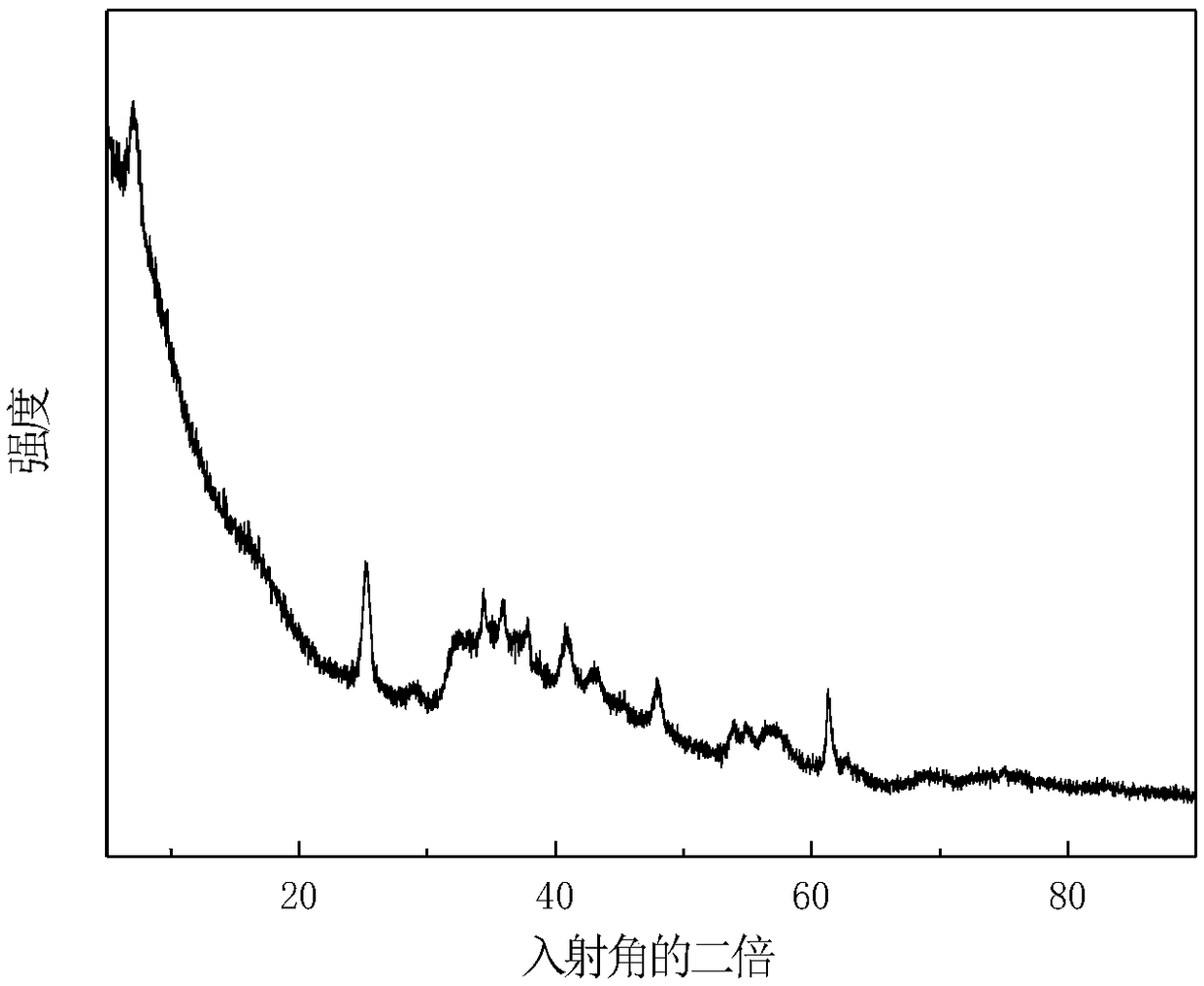

[0025] Such as figure 2 As shown, it can be seen that the composite of molybdenum disulfide and titanium carbide is relatively uniform.

[0026] Such as imag...

Embodiment 2

[0028] Add 0.6 gram of sodium molybdate, 1 gram of thioacetamide, 0.33 gram of titanium carbide, and 45 mL of deionized water into a stainless steel reactor with a volume of 75 ml, stir for 30 minutes, seal it, and fill it with 60%; Place it in a crucible boiler, heat it at 200°C for 16 hours, then wait for the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed three times successively with absolute ethanol, dilute hydrochloric acid and distilled water, filtered, and then vacuum-dried at 60°C for 12 hours to obtain a molybdenum disulfide / titanium carbide composite material with excellent electrochemical properties.

[0029] Such as Figure 4 As shown, it can be seen that the rate performance of the molybdenum disulfide / titanium carbide composite is relatively excellent.

Embodiment 3

[0031] Add 0.6 gram of ammonium molybdate, 1 gram of thiourea, 0.33 gram of titanium carbide, and 45 mL of deionized water into a stainless steel reaction kettle with a volume of 75 ml, stir for 10 minutes, seal, and the filling volume is 60%; In a crucible boiler, heat at 180° C. for 20 hours, then allow the reaction kettle to cool down to room temperature naturally, and take out the mixture. The above mixture was washed 5 times with absolute ethanol, dilute hydrochloric acid and distilled water successively, filtered, and then vacuum-dried at 60°C for 12 hours to obtain a molybdenum disulfide / titanium carbide composite material with excellent electrochemical properties.

[0032] Such as Figure 5 As shown, it can be seen that the rate performance of the molybdenum disulfide / titanium carbide composite is relatively excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com