Fermentation technology degrading tannin in moringa oleifera leaf powder by using fungi and moringa leaf feed prepared by technology

A fermentation process and technology of Moringa leaf powder, applied in the field of feed microorganisms, can solve problems such as limiting the addition and application of Moringa, and achieve the effects of reducing the content of tannin anti-nutritional factors, improving crude protein, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Isolation and identification of embodiment 1 polypolymycetes

[0023] Utilize degrading tannin microbial screening medium (800mL beef extract peptone agar medium, 100mL10% tannin aqueous solution, 100mL 0.04% bromophenol blue aqueous solution, pH 6.0, 121 ℃ of sterilization 20 minutes) carry out screening to Moringa oleifera root soil microorganism , to obtain a microorganism with the ability to degrade moringa tannins.

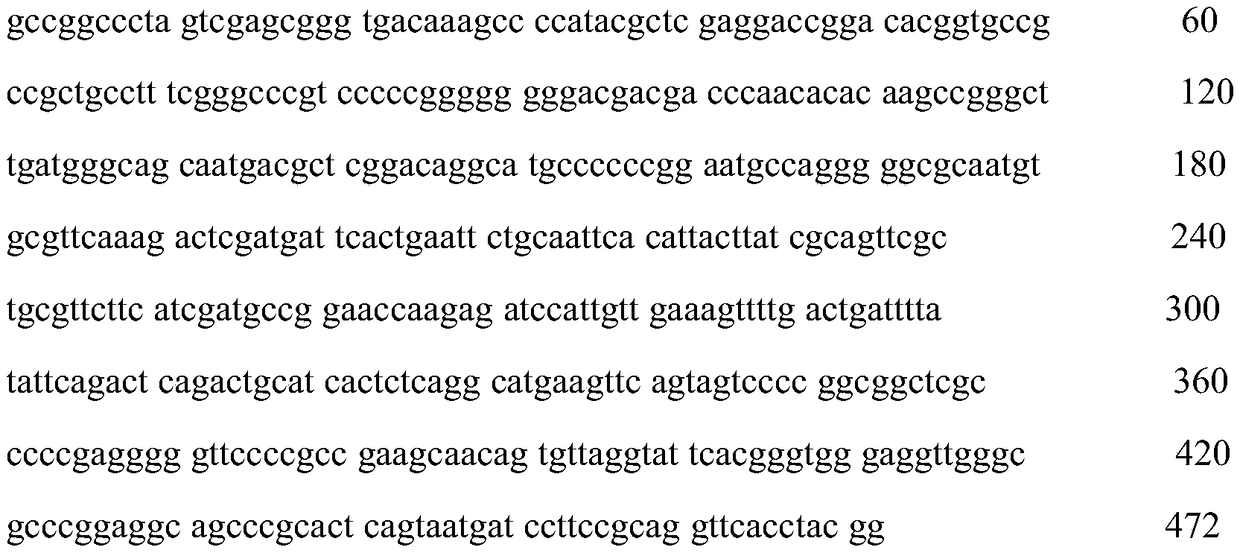

[0024] Use primers ITS1 (sequence: TCCGTAGGTGAACCTGCGG) and ITS4 (sequence: TCCTCCGCTTATTGATATGC) to perform PCR amplification on the screened tannin-degrading strain gene, and finally sequence the PCR-amplified product. The sequence determination was completed by Shanghai Handsome Biotechnology Co., Ltd. The sequencing results are as follows:

[0025]

[0026] The measured sequence was submitted to NCBI (National Center for Biotechnology Information), and the result showed that the sequence was 100% homologous to Aspergillus polypolyphaga. It sho...

Embodiment 2

[0027] The preparation of embodiment 2 fermented Moringa leaf feed

[0028] 1. preparation of spore suspension: first, aspergillus polydoctoris is cultivated on potato sucrose agar (PDA) slant medium (potato extract 1000mL, glucose 20g, agar 20g, pH 6.0, 121 ℃ of sterilization 20 minutes.) ( 30°C, 5 days), commercially available PDA medium can also be used. Then, after the spores grew out, the spores were washed down with 0.85% normal saline and diluted to 1×10 6 / ml of spore suspension.

[0029] 2. Moringa leaf mixture preparation: Moringa mixture is made up of 80% Moringa leaf powder and 20% starch, meanwhile, adds glucose (30g‰), NaNO 3 (3g‰), KH 2 PO 4 (1g‰),

[0030] MgSO 4 (0.5g‰), KCl (0.5g‰), FeSO 4 (0.01g‰).

[0031] 3. Moringa leaf feed solid fermentation process: the mass ratio of Moringa mixture to added water is 1:1; temperature: 30°C, spore suspension inoculation amount: 5%. Stir evenly, put in a triangular flask for fermentation, seal and ferment with s...

Embodiment 3

[0035] The preparation of embodiment 3 fermented Moringa leaf feed

[0036] 1. Preparation of spore suspension: first, Aspergillus polydoctoris was cultivated on PDA agar slant medium (potato extract 1000mL, glucose 20g, agar 20g, pH 6.0, 121 ℃ of sterilization 20 minutes.) (30 ℃, 5 sky). Then, after the spores grew out, the spores were washed down with 0.85% normal saline and diluted to 1×10 6 / ml of spore suspension.

[0037] 2. Moringa leaf mixture preparation: Moringa mixture is made up of 80% Moringa leaf powder and 20% starch, meanwhile, add glucose (30‰), NaNO 3 (3g‰), KH 2 PO 4 (1‰), MgSO 4 (0.5‰), KCl(0.5‰), FeSO 4 (0.01‰).

[0038] 3. Moringa leaf feed solid fermentation process: the weight ratio of Moringa leaf mixture to the volume of added water is 1:1; temperature: 30°C, spore suspension inoculum amount: 3%. Stir evenly, put in a triangular flask for fermentation, seal and ferment with sterilized newspaper for 6 days, and obtain fermented Moringa oleifera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com