Canned meat and production technology thereof

A production process and canning technology, which is applied in the field of canned meat and its production process, can solve the problems of affecting the appetite of the eaters, the fragrance is not strong enough, and the taste is not good, so as to enhance the laxative effect, prevent and treat diabetes, and enhance the inhibition of diabetes. The effect of the effect of the blood sugar rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

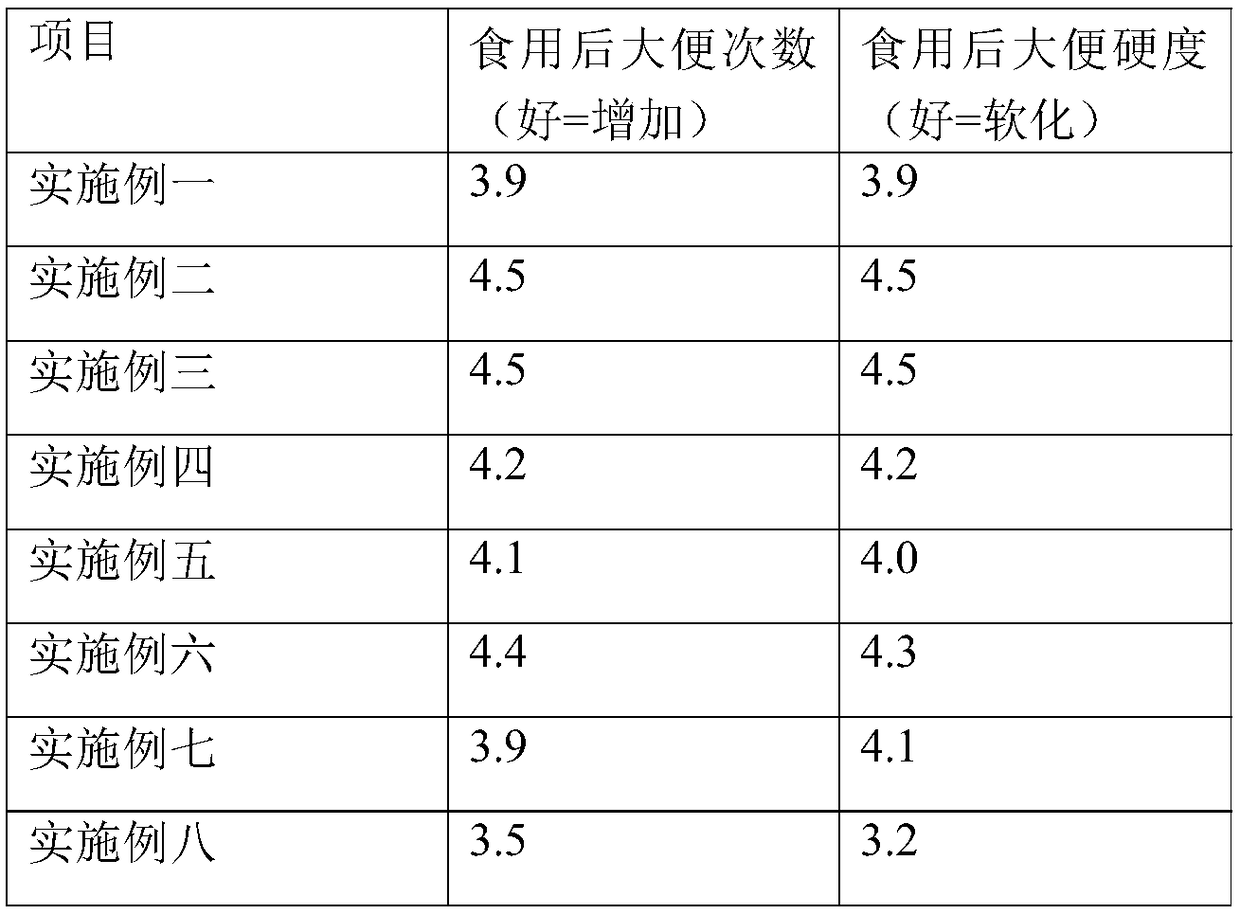

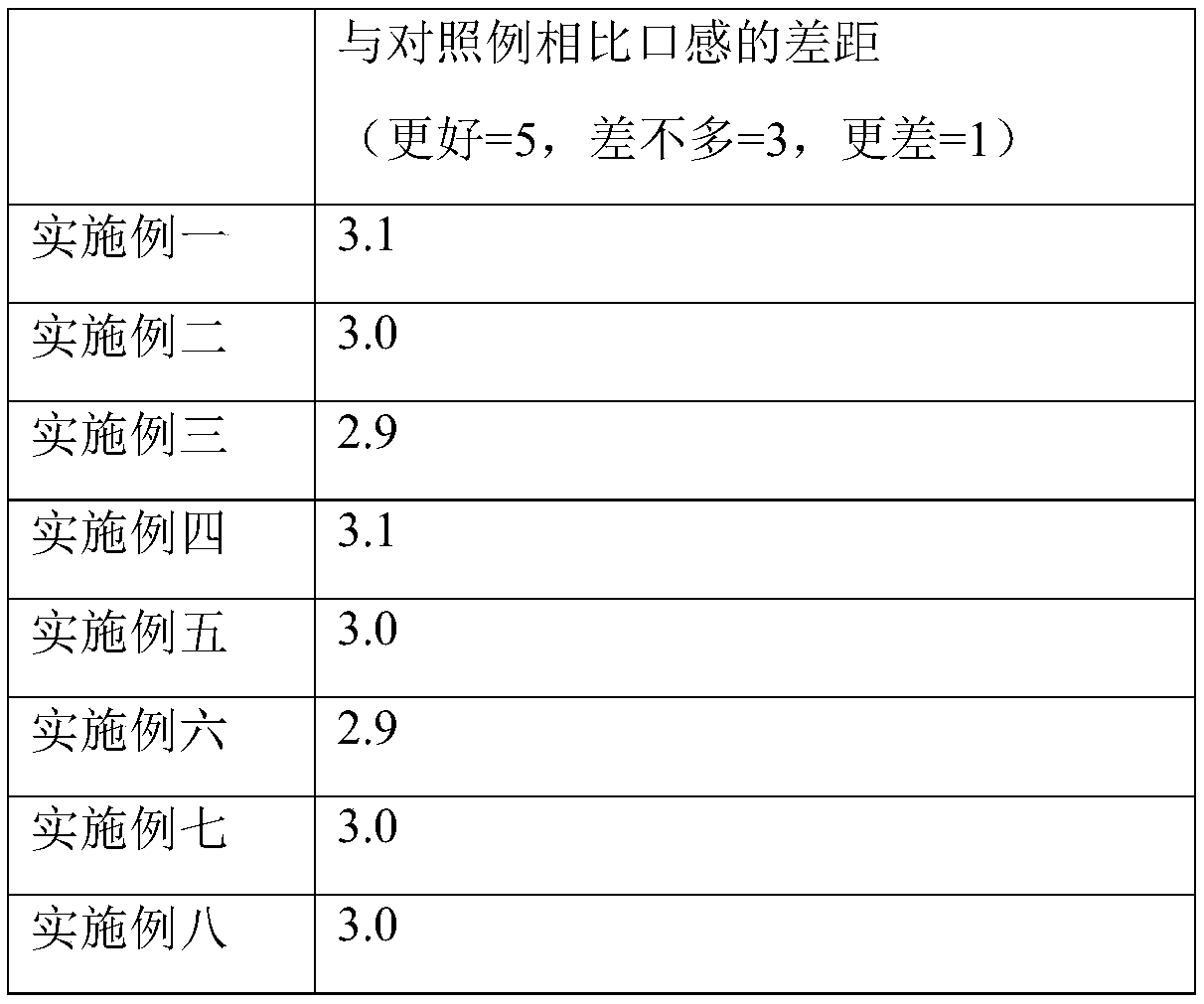

Examples

Embodiment 1

[0030] A canned meat, comprising the following raw materials in parts by weight: 60 parts of pork, 2 parts of cornstarch, 1 part of rice wine, 0.5 part of table salt, 0.5 part of L-arabinose, 0.7 part of xylan, and 0.01 part of compound phosphate , 0.2 parts of carrageenan, 0.02 parts of spices, 0.01 parts of ginger, 0.005 parts of D-isoascorbic acid, 0.5 parts of sodium alginate and 0.5 parts of plant extract.

[0031] The plant extract is the water extract of astragalus, tangerine peel, mulberry leaves and jujube. The production process of the plant extract is as follows: add 9 parts of astragalus, 3 parts of tangerine peel, 5 parts of mulberry leaves, and 2 parts of jujube into 80 parts by weight of pure water, and boil it for 2.5 hours after boiling. Finally, filter off the solid residue and take the filtrate to cool. In this embodiment, in the raw pork, the weight ratio of fat meat to lean meat is 1:9.

[0032] Wherein, the spice is a mixture of star anise, cinnamon, fe...

Embodiment 2

[0040] A canned meat, comprising the following raw materials in parts by weight: 60 parts of beef, 5 parts of cornstarch, 3 parts of rice wine, 1.5 parts of table salt, 0.5 part of L-arabinose, 1.3 parts of xylan, and 0.03 part of compound phosphate , 0.35 parts of konjac gum, 0.04 parts of spices, 0.015 parts of ginger, 0.01 parts of D-isoascorbic acid, 0.6 parts of sodium alginate and 1 part of plant extract.

[0041] The plant extract is the water extract of astragalus, tangerine peel, mulberry leaves and jujube. The production process of the plant extract is as follows: add 11 parts of astragalus, 6 parts of tangerine peel, 6 parts of mulberry leaves, and 2 parts of jujube into 80 parts by weight of pure water, boil it, and continue to boil it for 2.1 hours Finally, filter off the solid residue and take the filtrate to cool.

[0042] In this embodiment, in the raw beef, the weight ratio of fat meat to lean meat is 1:3. Wherein, the spice is a mixture of star anise, cinna...

Embodiment 3

[0049] A canned meat, comprising the following raw materials in parts by weight: 62 parts of pork, 5 parts of cornstarch, 2 parts of rice wine, 0.8 part of table salt, 0.7 part of L-arabinose, 1.3 parts of xylan, and 0.02 part of compound phosphate , 0.3 parts of konjac gum, 0.035 parts of spices, 0.018 parts of ginger, 0.008 parts of D-isoascorbic acid, 0.6 parts of sodium alginate and 0.8 parts of plant extract.

[0050] The plant extract is the water extract of astragalus, tangerine peel, mulberry leaves and jujube. The production process of the plant extract is as follows: add 12 parts of astragalus, 6 parts of tangerine peel, 6 parts of mulberry leaves, and 2 parts of jujube into 80 parts by weight of pure water, boil it, and continue to boil it for 2.5 hours Finally, filter off the solid residue and take the filtrate to cool.

[0051] In this embodiment, in the raw beef, the weight ratio of fat meat to lean meat is 1:3. Wherein, the spice is a powdered mixture of star ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com