Hyaluronic acid modified mitochondria target liposome and preparation method thereof

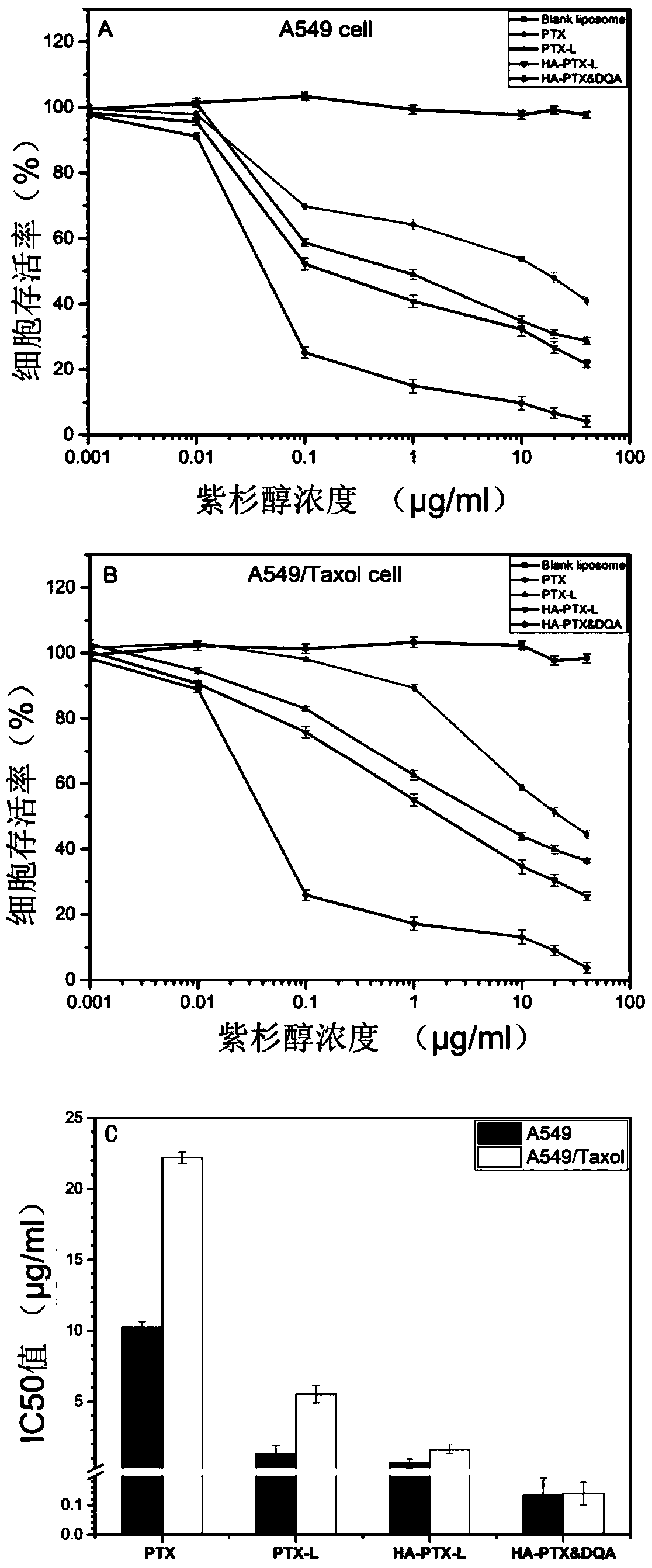

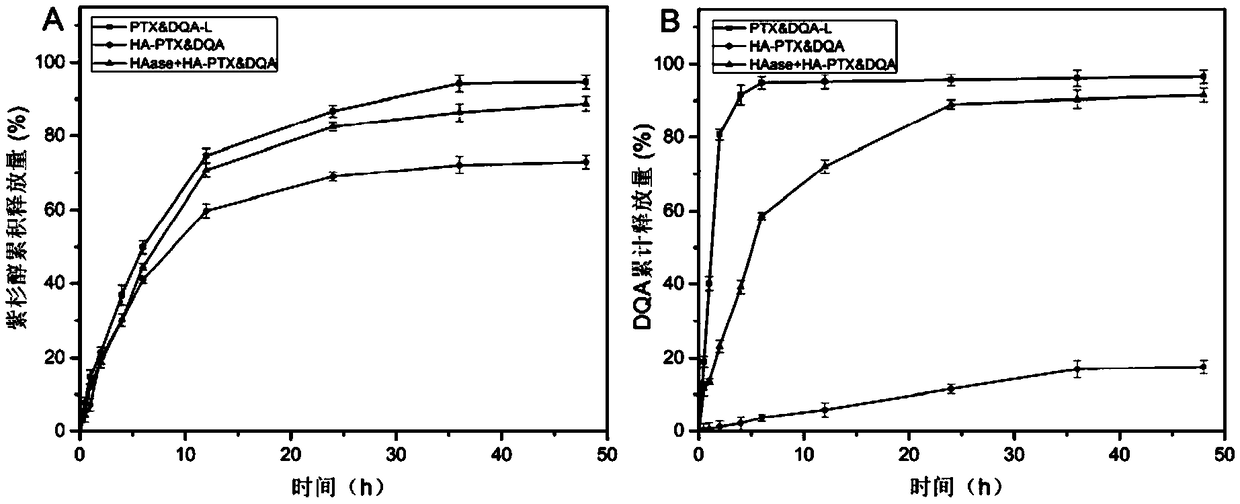

A hyaluronic acid modified and targeted liposome technology, which is applied in liposome delivery, medical preparations containing non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of paclitaxel’s anti-tumor effect, etc. Achieve the effect of avoiding systemic toxic and side effects, increasing drug concentration, and increasing circulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

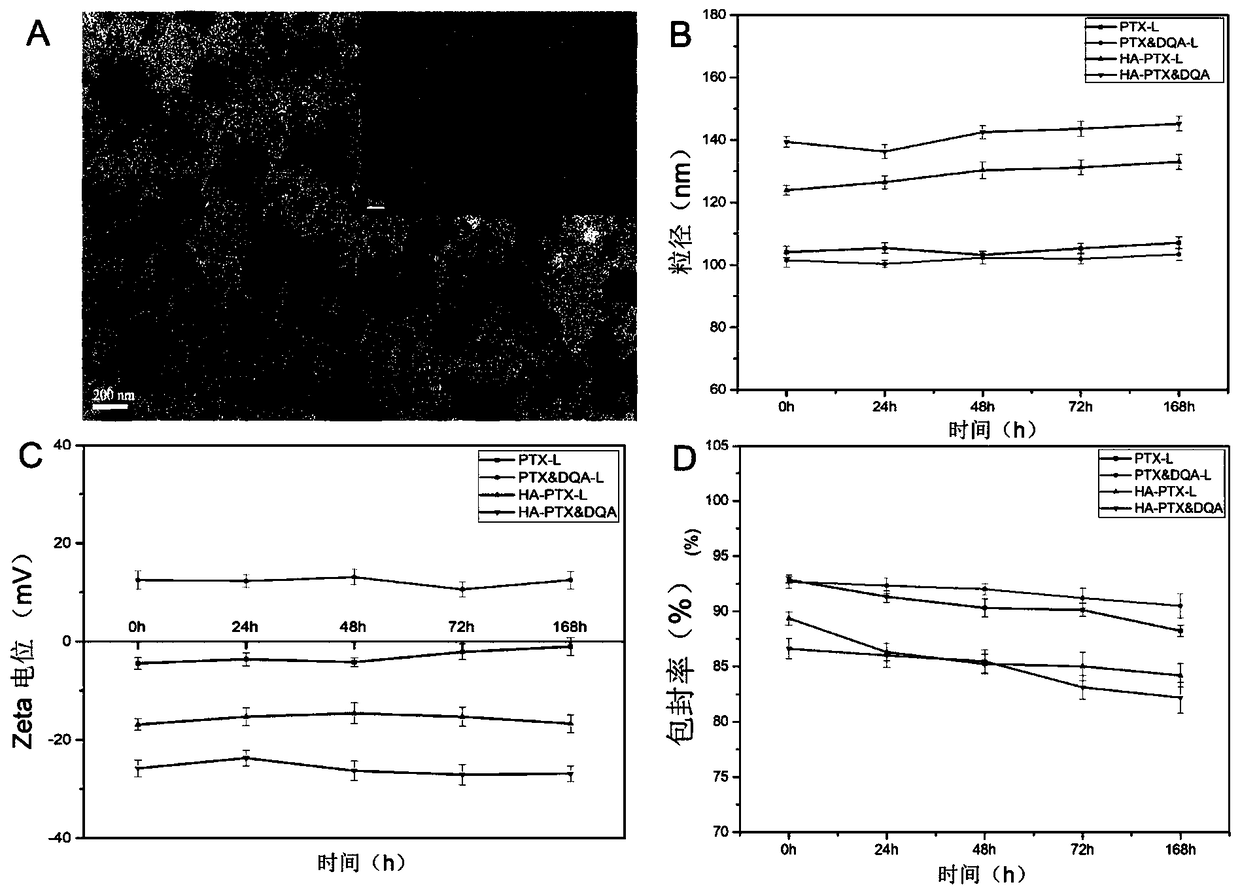

[0029] A preparation method of hyaluronic acid-modified mitochondria-targeted paclitaxel liposomes

[0030] Dissolve egg yolk lecithin, cholesterol, paclitaxel and dequalinium chloride in a mixed solution of chloroform:methanol 1:1 according to the molar ratio of 95:5:10:20, evaporate to dryness with a rotary evaporator to form a thin film and continue vacuum drying 1h, then add 100ml of 0.02M phosphate buffer solution, hydrate in a water bath at 40°C, and disperse the lipid film evenly, and hydrate the liposomes at 40°C for 1h. The hydrated liposome suspension was passed through a film squeezer equipped with a 100nm polycarbonate film, and the film was squeezed 10 times at 50°C. The activated hyaluronic acid was added dropwise to the prepared liposomes at a mass ratio of 1:20, and reacted overnight in a shaker. The particle size, zeta and PDI of the sample were measured by a particle size analyzer, the paclitaxel concentration of the liposome was measured by high performance...

Embodiment 2

[0033] A preparation method of hyaluronic acid-modified mitochondria-targeted paclitaxel liposomes

[0034] Dissolve hydrogenated soybean phospholipid HSPC, dioleoylphosphatidylethanolamine DOPE, cholesterol, paclitaxel and dequalinium chloride in a mixed solution of chloroform:methanol 1:1 according to the molar ratio of 60:35:5:5:10, and use rotary evaporation Evaporate it into a thin film and continue vacuum drying for 1 hour, then add 100ml of 0.02M phosphate buffer solution, hydrate in a water bath at 40°C, and disperse the lipid film evenly, and hydrate the liposomes at 40°C for 1 hour. The hydrated liposome suspension was passed through a film squeezer equipped with a 100nm polycarbonate film, and the film was squeezed 10 times at 50°C. The activated hyaluronic acid was added dropwise to the prepared liposomes at a mass ratio of 1:20, and reacted overnight in a shaker. The particle size, zeta and PDI of the sample were measured by a particle size analyzer, the paclitax...

Embodiment 3

[0037] A preparation method of hyaluronic acid-modified mitochondria-targeted paclitaxel liposomes

[0038]Dissolve soybean lecithin, cholesterol, paclitaxel and dequalinium chloride in a mixed solution of chloroform:methanol 1:1 according to the molar ratio of 60:35:5:10:15, evaporate it to dryness with a rotary evaporator to form a thin film and keep vacuuming Dry for 1 hour, then add 100ml of 0.02M phosphate buffer solution, hydrate in a water bath at 40°C, and disperse the lipid film evenly, and hydrate the liposomes at 40°C for 1 hour. The hydrated liposome suspension was circulated 3 times at 300 bar at 50°C under the action of a homogenizer, and homogenized 10 times at 1100 bar. The activated hyaluronic acid was added dropwise to the prepared liposomes at a mass ratio of 1:20, and reacted overnight in a shaker. The particle size, zeta and PDI of the sample were measured by a particle size analyzer, the paclitaxel concentration of the liposome was measured by high perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com