Clay sand system dust recycling technology

The technology of clay sand and dust is applied in the field of dust recycling technology of clay sand system, which can solve the problems of pollution and waste of raw materials and the environment, and achieve the effect of reducing production cost and adding amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

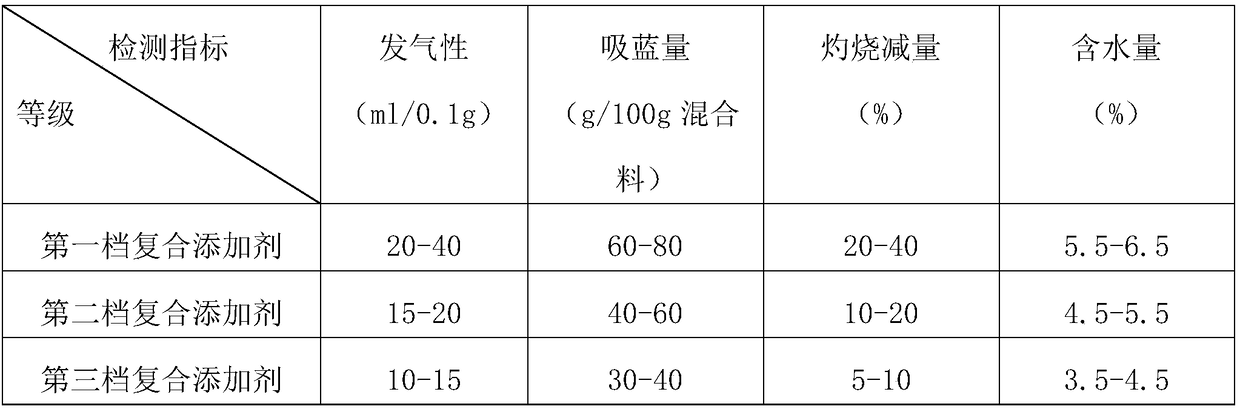

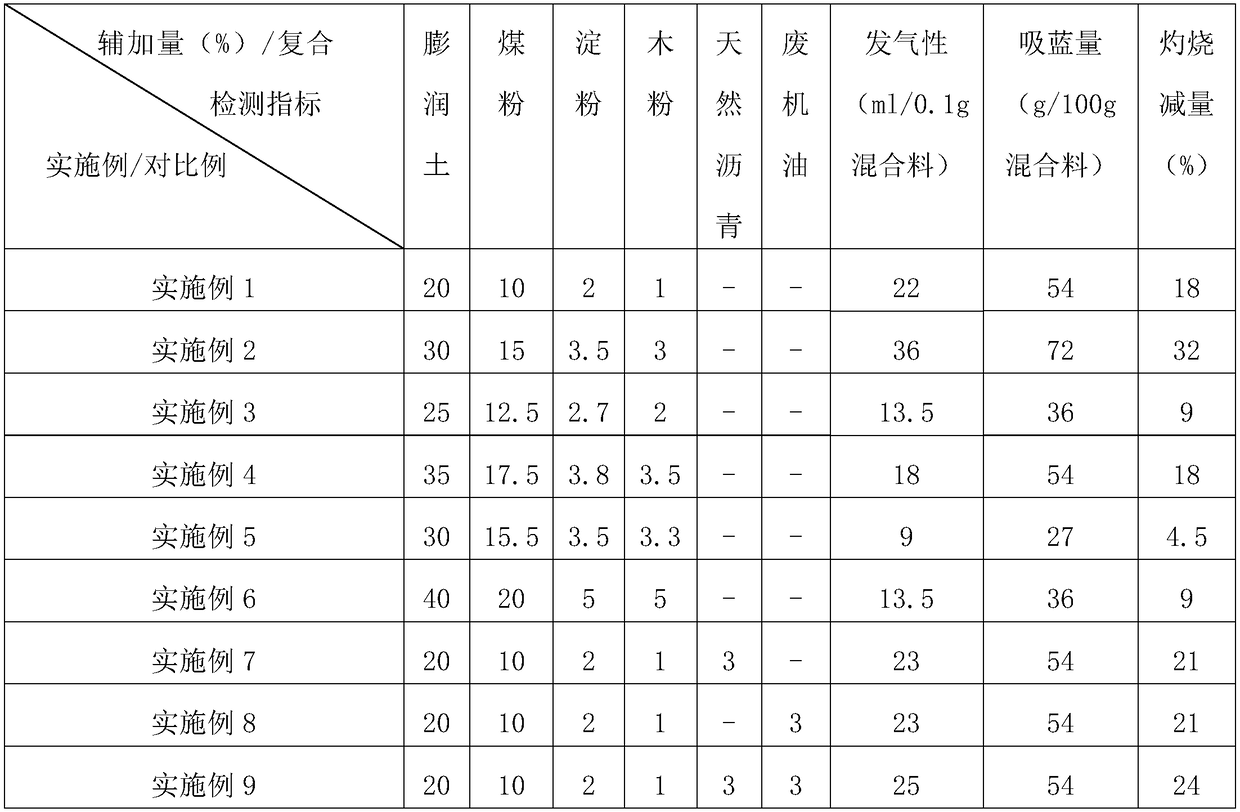

[0031] According to the detection of gas generation, blue absorption, burning loss and water content in the dust, auxiliary materials are added to the dust to obtain Examples 1-9. Among them, Example 1 and Example 2 belong to the first grade composite additive; Embodiment 3 and Embodiment 4 belong to the second grade composite additive; Embodiment 5 and Embodiment 6 belong to the third grade composite additive.

[0032] The additional amount of auxiliary material (hereinafter referred to as auxiliary amount) and the detection index of composite additive (hereinafter referred to as composite detection index) of each embodiment, specifically refer to the following table 2:

[0033]

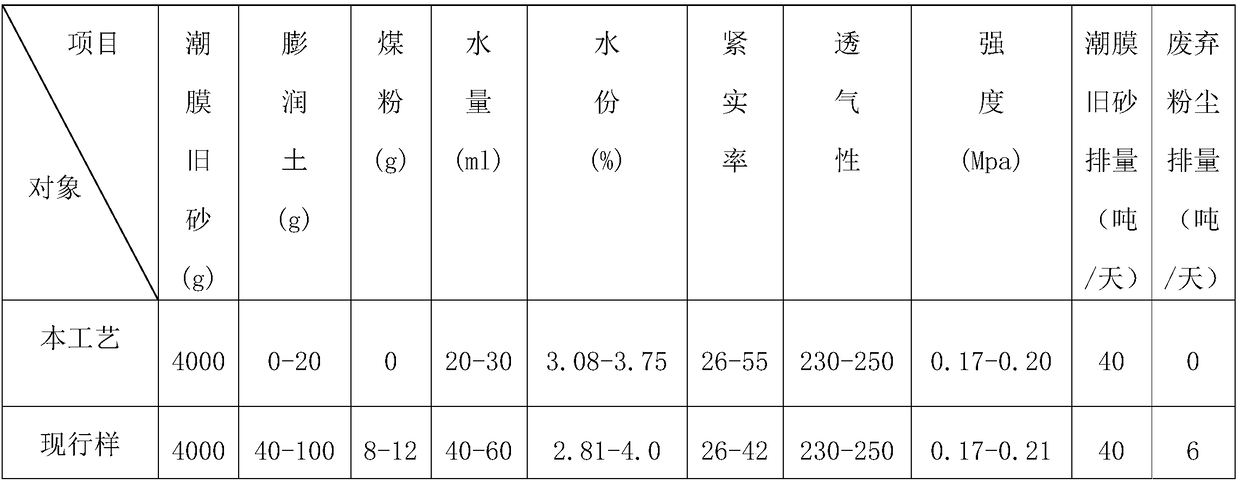

[0034] The comparison of the effect of this process (wet film old sand + composite additive) with the current sample (wet film old sand + bentonite + coal powder) is shown in Table 3 below.

[0035]

[0036] in conclusion:

[0037] It can be obtained from Table 3:

[0038] 1) When the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com