Preparation method of high-strength high-temperature-resistant glass cotton

A glass wool, high temperature resistant technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low mechanical strength, cellulose breakage, and high brittleness of glass wool, and achieve improved comprehensive performance, good elasticity, and good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

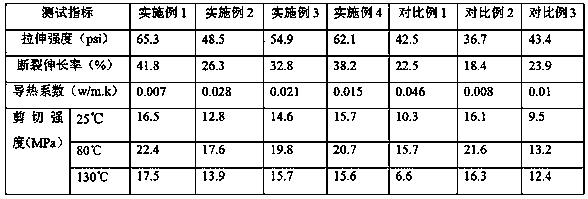

Examples

Embodiment 1

[0026] A preparation method of high-strength and high-temperature-resistant glass wool, comprising the following steps:

[0027] (1) Put 70 parts of waste glass, 30 parts of calcite and 20 parts of nano-alumina into water to wash and remove impurities, collect the precipitated particles after removing impurities, dry the precipitated particles in an oven, and mix the precipitated raw materials with 15 parts of borax and 9 parts of carbon nanotubes are mixed, and placed in a pulverizer for pulverization, passing through a 60-mesh sieve, and collecting the sieved particles;

[0028] (2) Mix the sieved particles prepared in step (1) with 9 parts of calcium oxide, 7 parts of magnesium silicate, and 5.5 parts of titanium dioxide, and then put them into a ball mill for ball milling to collect the ball mill; put the ball mill into In a melting furnace, melt at 850°C to obtain molten glass;

[0029] (3) Put the molten glass into a glass wool centrifuge for centrifugal blowing to prod...

Embodiment 2

[0037] A preparation method of high-strength and high-temperature-resistant glass wool, comprising the following steps:

[0038] (1) Put 60 parts of waste glass, 20 parts of calcite and 15 parts of nano-alumina into water to wash and remove impurities, collect the precipitated particles after removing impurities, dry the precipitated particles in an oven, and mix the precipitated raw materials with 12 parts of borax and 6 parts of carbon nanotubes are mixed, and placed in a pulverizer for pulverization, passing through a 30-mesh sieve, and collecting the sieved particles;

[0039] (2) Mix the sieved particles prepared in step (1) with 7 parts of calcium oxide, 5 parts of magnesium silicate, and 4 parts of titanium dioxide, and then put them into a ball mill for ball milling to collect the ball mill; put the ball mill into Melting in a melting furnace at 800°C to obtain molten glass;

[0040] (3) Put the molten glass into a glass wool centrifuge for centrifugal blowing to prod...

Embodiment 3

[0048] A preparation method of high-strength and high-temperature-resistant glass wool, comprising the following steps:

[0049] (1) Put 65 parts of waste glass, 25 parts of calcite and 18 parts of nano-alumina into water to wash and remove impurities, collect the precipitated particles after removing impurities, dry the precipitated particles in an oven, and mix the precipitated raw materials with 14 parts of borax and 8 parts of carbon nanotubes are mixed, and placed in a pulverizer for pulverization, passing through a 40-mesh sieve, and collecting the sieved particles;

[0050] (2) Mix the sieved particles prepared in step (1) with 8 parts of calcium oxide, 6 parts of magnesium silicate, and 5 parts of titanium dioxide, and then put them into a ball mill for ball milling to collect the ball mill; put the ball mill into Melting in a melting furnace at 820°C to obtain molten glass;

[0051] (3) Put the molten glass into a glass wool centrifuge for centrifugal blowing to prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com