Polybenzimidazole compound with pendant group containing fluorine, and preparation method thereof

A technology of polybenzimidazole and benzimidazole is applied in the field of polybenzimidazole compounds and their preparation, which can solve the problems of performance and battery performance decline, fracture, etc., and achieves improved solubility, good process controllability, and broad application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The ratio of raw materials used is as follows:

[0054]

[0055] Preparation method of polybenzimidazole compound modified film containing fluorine side groups:

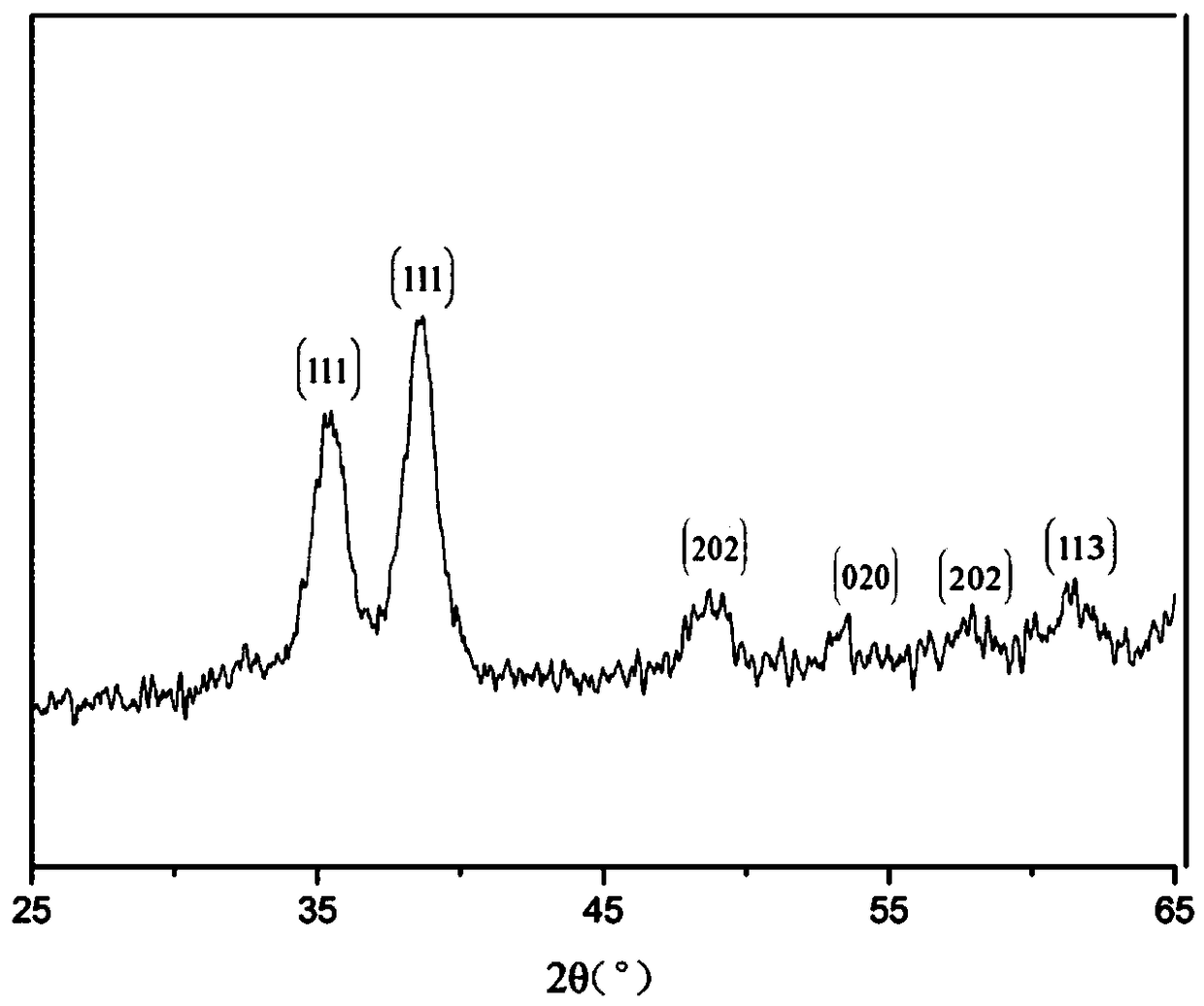

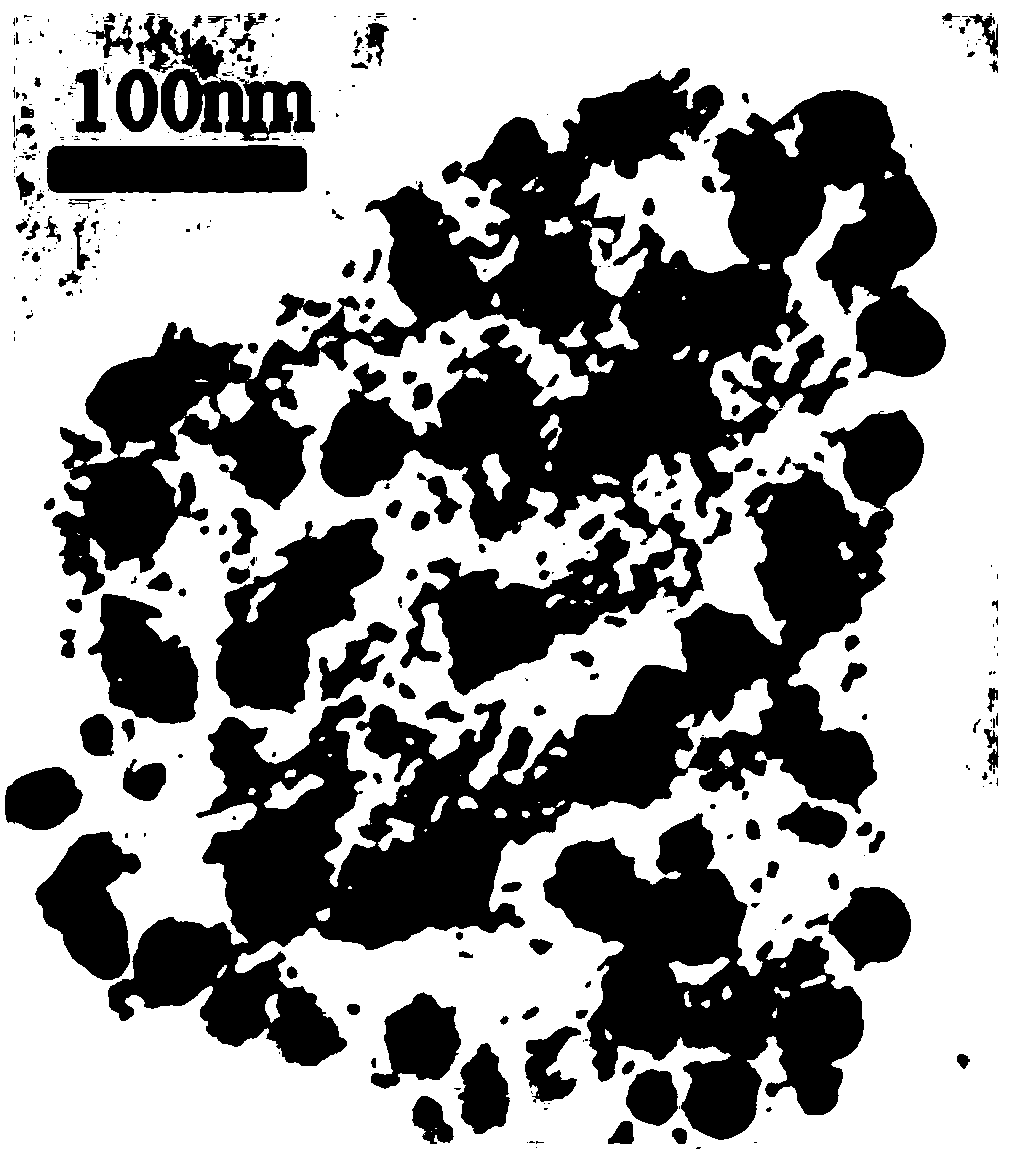

[0056] (1) Mix 1mL of glacial acetic acid and 300mL of 0.02mol / L copper acetate solution in a round bottom flask evenly, heat to 100°C under vigorous stirring, then quickly add 0.8g of NaOH (flaky) into the boiling solution After the reaction, a large amount of black precipitates were generated, and after centrifugation, washing and other post-treatments, the heterogeneous catalyst nano-CuO was obtained.

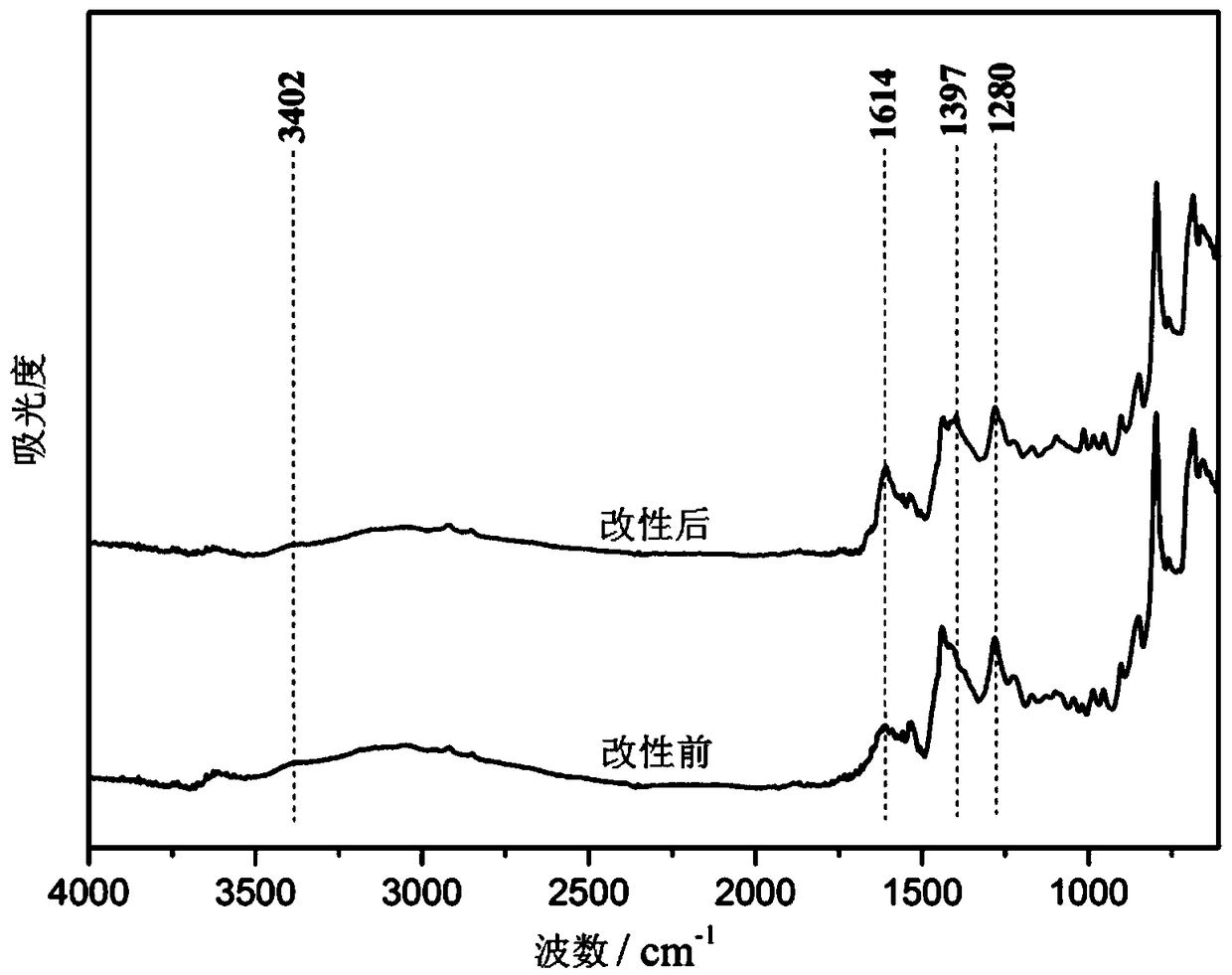

[0057] (2) Dissolve the synthesized poly(2,2'-m-phenylene-5,5'-benzimidazole) (PBI-ph) in N,N-dimethylacetamide (DMAc) to prepare PBI-ph Solution, add polybenzimidazole 2g in every 100mL DMAc.

[0058] (3) Add catalyst nano-CuO, p-chlorobenzotrifluoride, anhydrous potassium carbonate to the PBI-ph solution obtained in step (2) at normal temperature, gradually heat up to 120° C., condense and reflux for ...

Embodiment 2

[0070] The ratio of raw materials used is as follows:

[0071]

[0072] Preparation method of polybenzimidazole compound modified film containing fluorine side groups:

[0073] (1) Mix 1mL of glacial acetic acid and 300mL of 0.02mol / L copper acetate solution in a round bottom flask evenly, heat to 100°C under vigorous stirring, then quickly add 0.8g of NaOH (flaky) into the boiling solution After the reaction, a large amount of black precipitates were generated, and after centrifugation, washing and other post-treatments, the heterogeneous catalyst nano-CuO was obtained.

[0074] (2) Dissolve the synthesized poly(2,2'-m-phenylene-5,5'-benzimidazole) (PBI-ph) in N-methylpyrrolidone (NMP) to prepare PBI-ph solution, each 100mL Add 2 g of polybenzimidazole to NMP.

[0075] (3) Add catalyst nano-CuO, p-chlorobenzotrifluoride, and anhydrous potassium carbonate to the PBI-ph solution obtained in step (2) at room temperature, gradually heat up to 120° C., condense and reflux for...

Embodiment 3

[0079] The ratio of raw materials used is as follows:

[0080]

[0081]

[0082] Preparation method of polybenzimidazole compound modified film containing fluorine side groups:

[0083] (1) Mix 1mL of glacial acetic acid and 300mL of 0.02mol / L copper acetate solution in a round bottom flask evenly, heat to 100°C under vigorous stirring, then quickly add 0.8g of NaOH (flaky) into the boiling solution After the reaction, a large amount of black precipitates were generated, and after centrifugation, washing and other post-treatments, the heterogeneous catalyst nano-CuO was obtained.

[0084] (2) Dissolve the synthesized poly(2,2'-p-phenylene-5,5'-benzimidazole) (PBI-oct) in N,N-dimethylacetamide (DMAc) to prepare PBI-ph solution, adding 0.5 g of polybenzimidazole per 100 mL of DMAc.

[0085] (3) Add catalyst nano-CuO, p-chlorobenzotrifluoride, and anhydrous sodium carbonate to the PBI-ph solution obtained in step (2) at normal temperature, gradually heat up to 120° C., co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com