A kind of preparation method of starch-based pickering emulsion gel

An emulsion gel, starch-based technology, applied in the field of preparation of starch-based Pickering emulsion gel, can solve problems such as poor biodegradability and poor biocompatibility, achieve good emulsion stability, enhance stability, and reduce physical losses. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

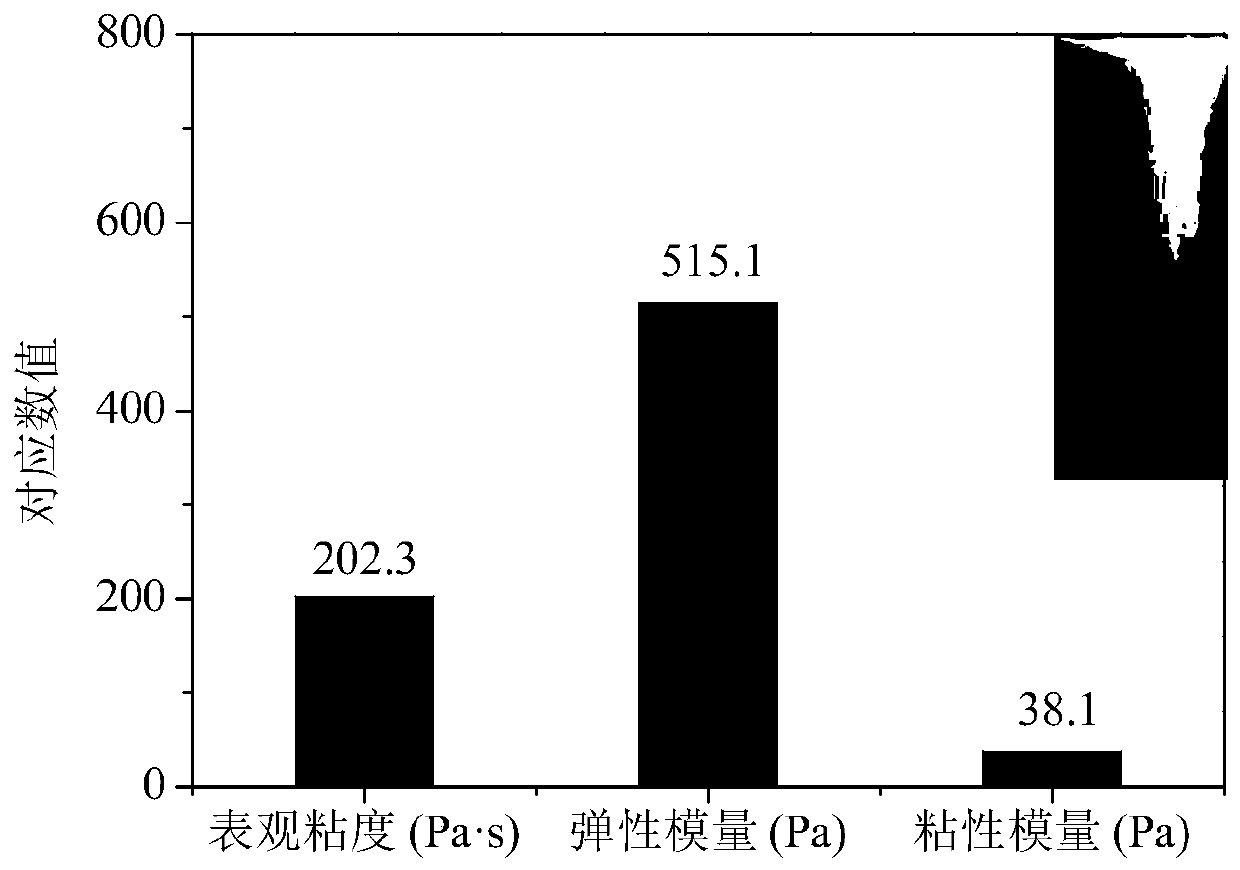

Embodiment 1

[0038] A kind of preparation method of starch-based Pickering emulsion gel, comprises the steps:

[0039] (1) Preparation of modified small-diameter starch granules: use 5wt% (mass ratio of octenyl succinic anhydride to starch) octenyl succinic anhydride to modify small starch granules with an average particle size of 1.6 μm by esterification , to obtain modified small-size starch granules with a degree of substitution of 0.028 and an average particle size of 1.6 μm;

[0040] (2) Dispersion, hydration: the modified small-diameter starch granules obtained in step (1) are uniformly dispersed in distilled water by solid-liquid mass fraction 4% (i.e. the mass ratio of modified small-diameter starch granules and distilled water), Continue stirring for 12 hours to make it fully hydrated to form a suspension solution of starch granules;

[0041] (3) refueling, emulsification: the starch granule suspension solution of step (2) gained is by oil-water volume fraction 70% (being the vol...

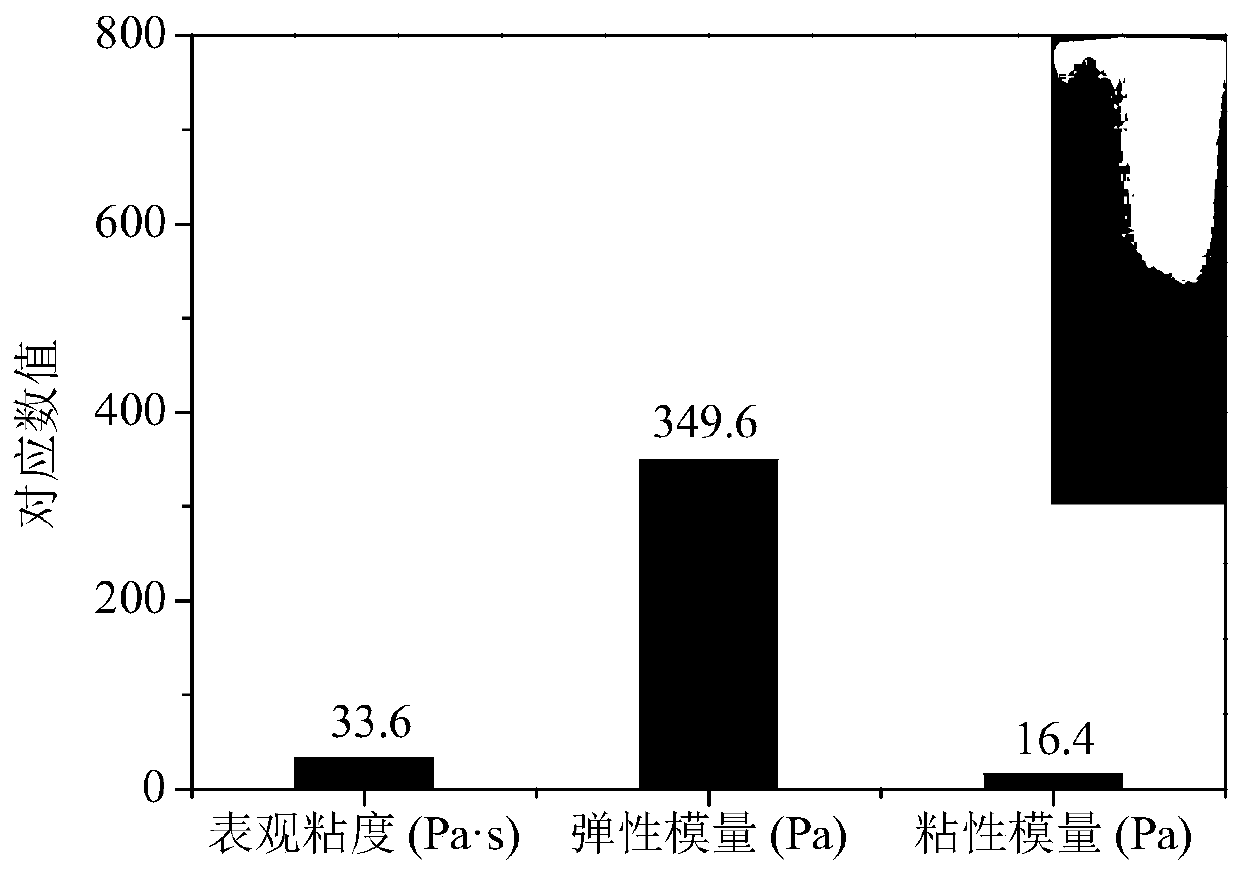

Embodiment 2

[0046] A kind of preparation method of starch-based Pickering emulsion gel, comprises the steps:

[0047] (1) Preparation of modified small-diameter starch granules: use 20wt% (mass ratio of octenyl succinic anhydride to starch) octenyl succinic anhydride to modify small starch granules with an average particle size of 3.2 μm by esterification , to obtain modified small-size starch granules with a degree of substitution of 0.100 and an average particle size of 3.2 μm;

[0048] (2) Dispersion, hydration: the modified small-diameter starch granules obtained in step (1) are uniformly dispersed in distilled water by solid-liquid mass fraction 4% (i.e. the mass ratio of modified small-diameter starch granules and distilled water), Continue stirring for 12 hours to make it fully hydrated to form a suspension solution of starch granules;

[0049] (3) Refueling and emulsification: the starch granule suspension solution obtained in step (2) is mixed with soybean oil according to the o...

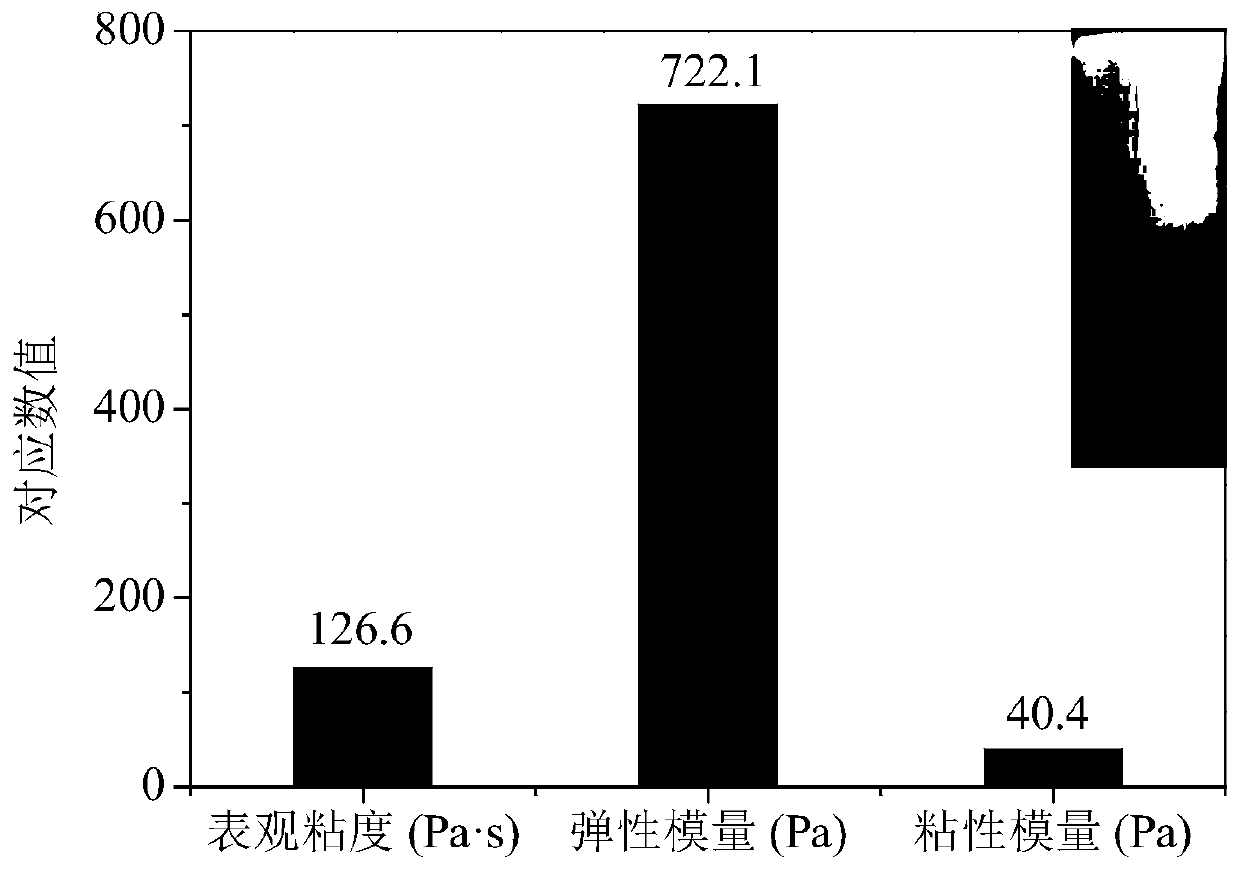

Embodiment 3

[0052] A kind of preparation method of starch-based Pickering emulsion gel, comprises the steps:

[0053] (1) Preparation of modified small-diameter starch granules: use 20 wt% (mass ratio of octenyl succinic anhydride to starch) of octenyl succinic anhydride to carry out esterification modification on small starch granules with an average particle size of 1.6 μm , to obtain modified small-size starch granules with a degree of substitution of 0.100 and an average particle size of 1.6 μm;

[0054] (2) Dispersion, hydration: the modified small-diameter starch granules obtained in step (1) are uniformly dispersed in distilled water by solid-liquid mass fraction 4% (i.e. the mass ratio of modified small-diameter starch granules and distilled water), Continue stirring for 12 hours to make it fully hydrated to form a suspension solution of starch granules;

[0055] (3) Refueling and emulsification: the starch granule suspension solution obtained in step (2) is mixed with soybean oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com