Preparation method of easily dispersible quaternary ammonium salt modified nano organic montmorillonite

A nano-organic, easy-to-disperse technology, applied in the treatment of dyeing low-molecular-weight organic compounds, chemical instruments and methods, and inorganic pigment treatment, etc. Mechanical properties, the effect of solving fatal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

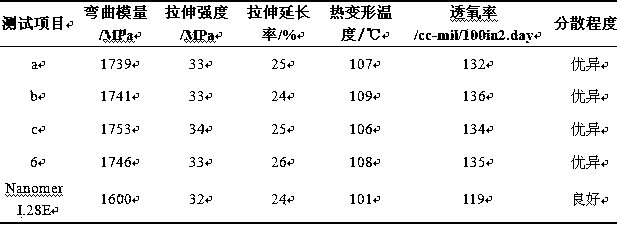

Examples

Embodiment 1

[0015] An easily dispersible quaternary ammonium salt modified nano-organic montmorillonite is prepared according to the following steps from the following raw material components in parts by mass:

[0016] (1) First, 100 parts of calcium-based montmorillonite (model: MS-C; produced by Zhejiang Fenghong New Material Co., Ltd.; the same below) and 1 part of La 2 o 3 Stir evenly, and then bake at 100°C for 10 minutes; then take it out and add 500 parts of pure water, stir well until it is completely dispersed to form a uniform solution;

[0017] (2) Then add 1 part of concentrated sulfuric acid and stir for 15 minutes, then filter and wash, and roast the filter cake at 80°C for 60 minutes, then take out the dried filter cake and add 500 parts of pure water, and add 1 part of Dy( NO 3 ) 3 , and continue to stir for 30min;

[0018] (3) Next, add 30 parts of quaternary ammonium salt octadecyltrimethylammonium bromide and raise the temperature of the reaction system to 65°C, kee...

Embodiment 2

[0020] An easily dispersible quaternary ammonium salt modified nano-organic montmorillonite is prepared according to the following steps from the following raw material components in parts by mass:

[0021] (1) First, 100 parts of Na-montmorillonite (model: MS-N2; produced by Zhejiang Fenghong New Material Co., Ltd.; the same below), 2.5 parts of Ce 2 o 3 , 2.5 Ln 2 o 3 Stir evenly, and then bake at 130°C for 20 minutes; then take it out and add 500 parts of pure water, stir well until it is completely dispersed to form a uniform solution;

[0022] (2) Then add 2 parts of concentrated sulfuric acid and 3 parts of concentrated hydrochloric acid and stir for 30 minutes, then filter and wash, and roast the filter cake at 100°C for 90 minutes, then take out the dried filter cake and add 500 parts of pure water, after fully stirring Add 3 servings of Dy2 (SO 4 ) 3 and 2 parts of Sr(NO 3 ) 2 , and continue to stir for 60min;

[0023] (3) Next, add 30 parts of dioctadecyldime...

Embodiment 3

[0025] An easily dispersible quaternary ammonium salt modified nano-organic montmorillonite is prepared according to the following steps from the following raw material components in parts by mass:

[0026] (1) First, mix 50 parts of sodium montmorillonite, 50 parts of calcium montmorillonite, and 0.5 parts of La 2 o 3 , 0.5 Ce 2 o 3 , 0.5 Ln 2 o 3 Stir evenly, and then bake at 110°C for 15 minutes; then take it out and add 500 parts of pure water, stir well until it is completely dispersed to form a uniform solution;

[0027] (2) Then add 1 part of concentrated hydrochloric acid, 1 part of dilute phosphoric acid with a mass fraction of 15%, and 1 part of dilute boric acid with a mass fraction of 10% and stir for 20 minutes, then filter, wash, and roast the filter cake at 85°C for 70 minutes. Then take out the dried filter cake and add 500 parts of pure water, stir well and add 0.8 parts of DyCl 3 , 0.9 parts of Sr(NO 3 ) 2 , 0.5 parts of SrSO 4 , and continue to stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com