High-temperature PTC (Positive Temperature Coefficient) self temperature limitation heat tracing belt and preparation method thereof

A technology of self-limiting temperature heating cables and heating cables, applied in the shape of heating elements, etc., can solve the problems of expensive fluorine-containing materials, unfavorable use of high-temperature heating cables, environmental pollution, etc., and achieve low cost, good heat and cold resistance performance, improve the effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

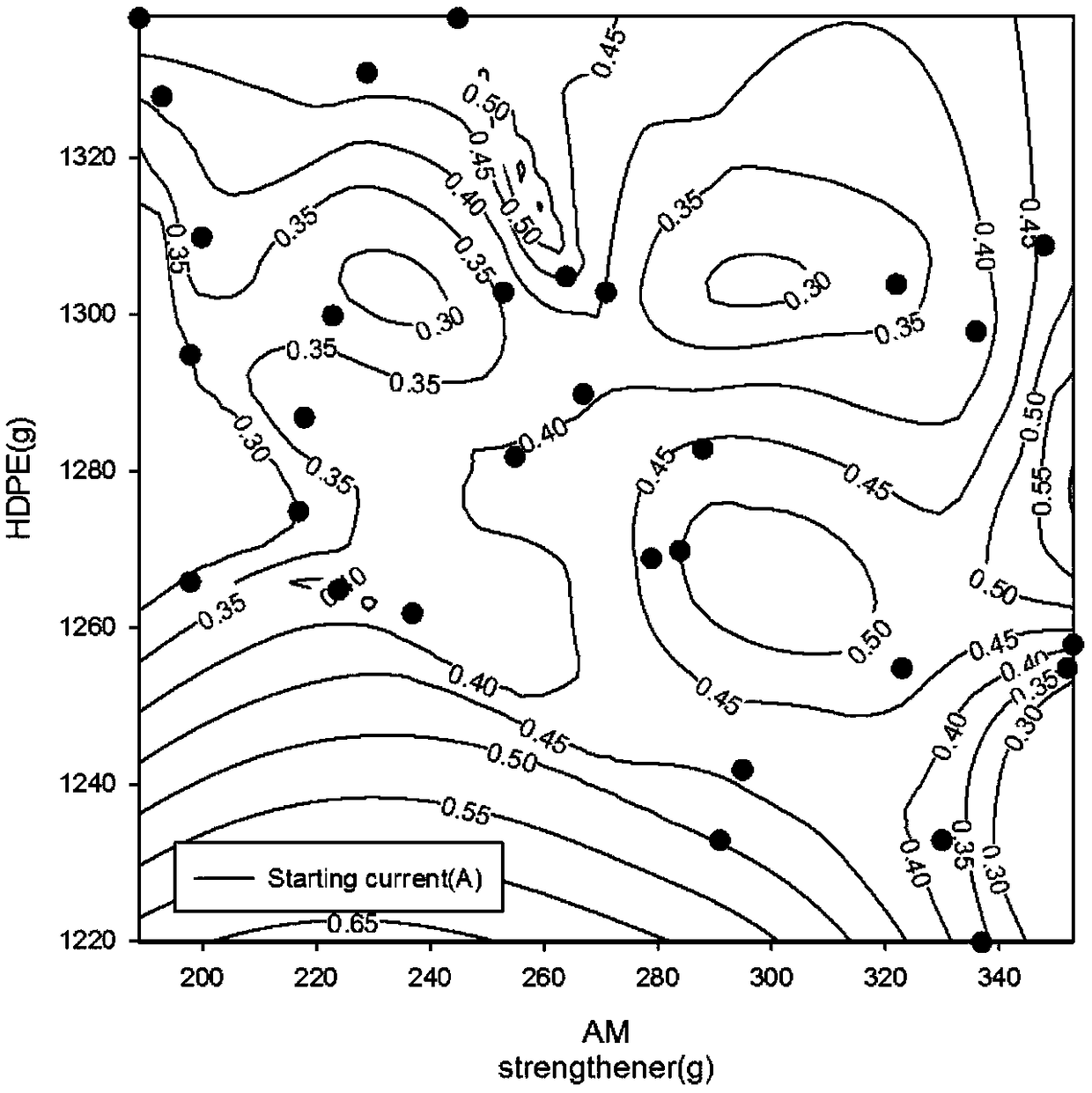

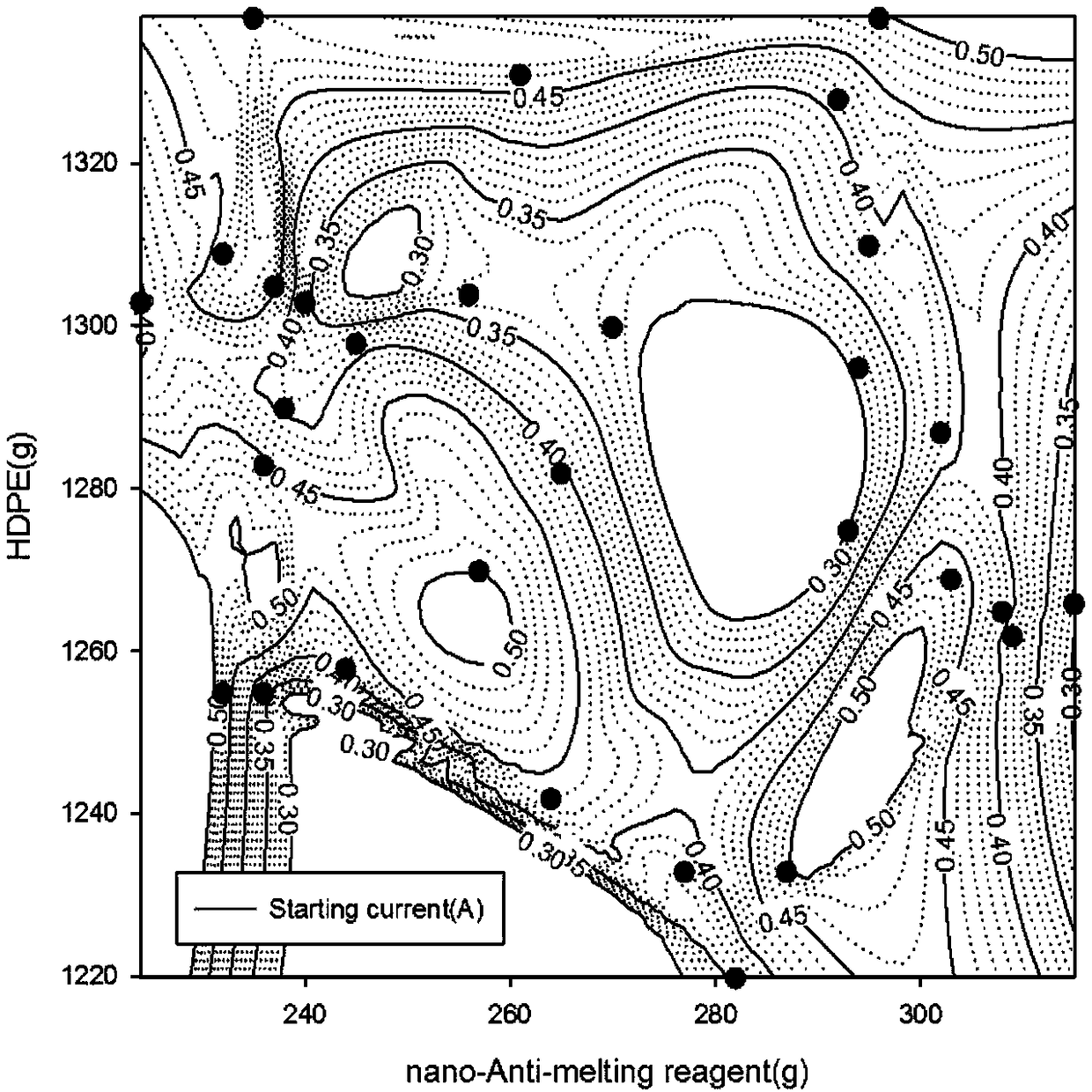

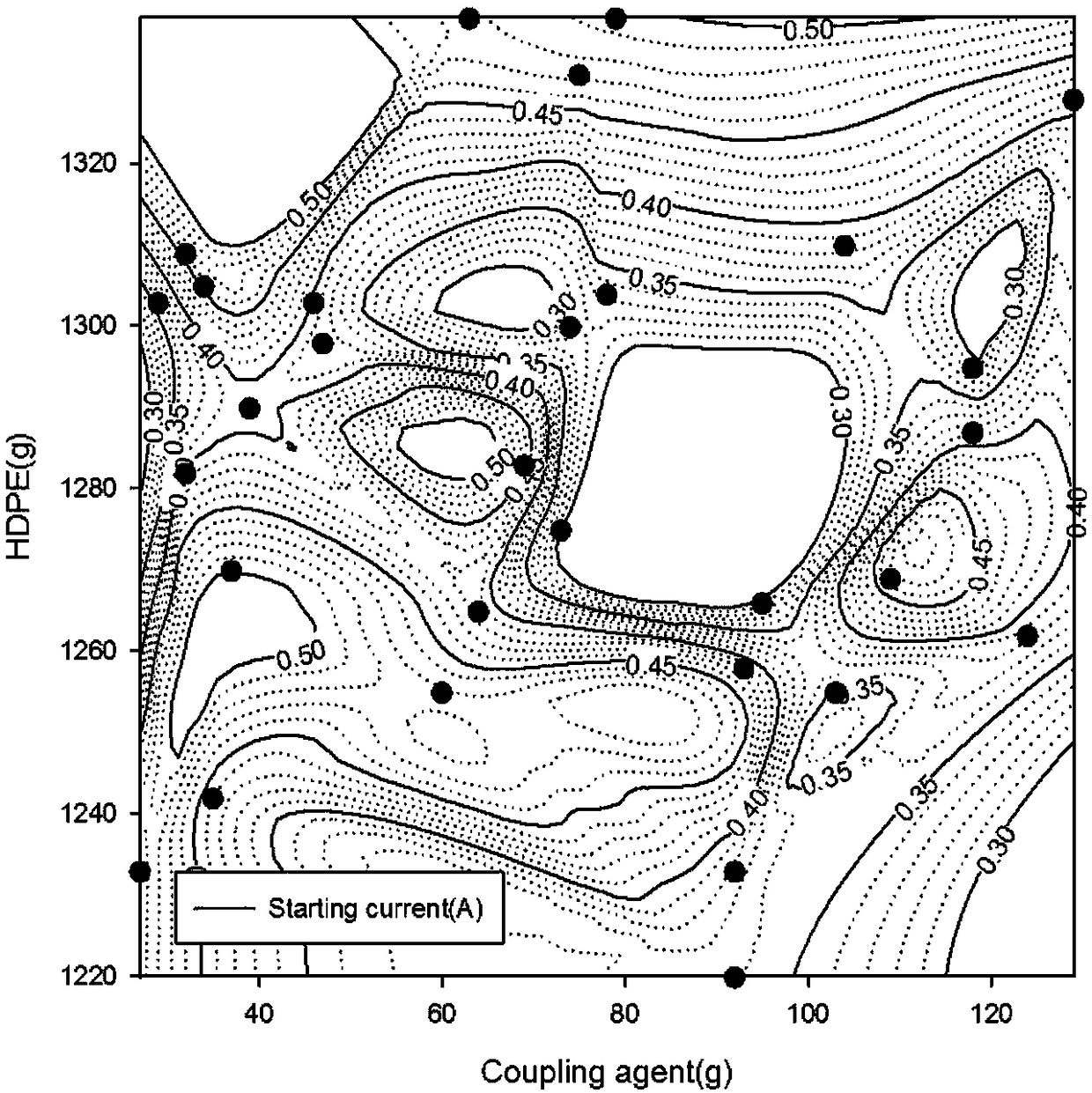

[0026] In this embodiment, the heating cable includes the following ingredients in parts by weight: 1270 parts of matrix HDPE, 37 parts of coupling agent, 284 parts of melting inhibitor, and 257 parts of reinforcing material.

[0027] The preparation method of the high-temperature PTC self-limiting temperature heating cable in this embodiment, the specific steps are as follows:

[0028] 1) Weigh 37 parts by weight of coupling agent vinyltriethoxysilane, 284 parts by weight of 98% purity, particle size distribution 0.5 μm, specific surface area 5m 3 / g ultra-fine magnesium hydroxide anti-melting agent and 257 parts by weight of E-glass fibers are placed in a plastic refining machine, and the temperature of the roller of the plastic refining machine is raised to 180 ° C. Add 1270 parts by weight of matrix material HDPE-7000F, and wait After the roll, add 62 parts by weight of carbon black, after mixing evenly, extrude into a thin sheet with a thickness of 2mm, and cut it into a ...

Embodiment 2

[0032] This example is the same as Example 1, except that the heating cable in this example includes the following ingredients in parts by weight: 1310 parts of matrix HDPE, 74 parts of coupling agent, 250 parts of anti-melting agent, and 257 parts of reinforcing material.

[0033] After 30 minutes, it was measured that the starting current was 0.31A, and the heating temperature was 125°C.

Embodiment 3

[0035] This example is the same as Example 1, except that the heating cable in this example includes the following ingredients in parts by weight: 1325 parts of matrix HDPE, 53 parts of coupling agent, 237 parts of anti-melting agent, and 240 parts of reinforcing material.

[0036] After 30 minutes, it was measured that the starting current was 0.48A, and the heating temperature was 163°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com