A kind of zno/co composite nano hollow fiber electromagnetic wave absorbing material and preparation method thereof

A technology for absorbing materials and hollow fibers, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, and other chemical processes, and can solve problems such as inability to use materials for large-scale and industrialized preparation, unfavorable practical application and industrial production, and high price , to achieve excellent electromagnetic wave absorption performance, excellent impedance matching performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

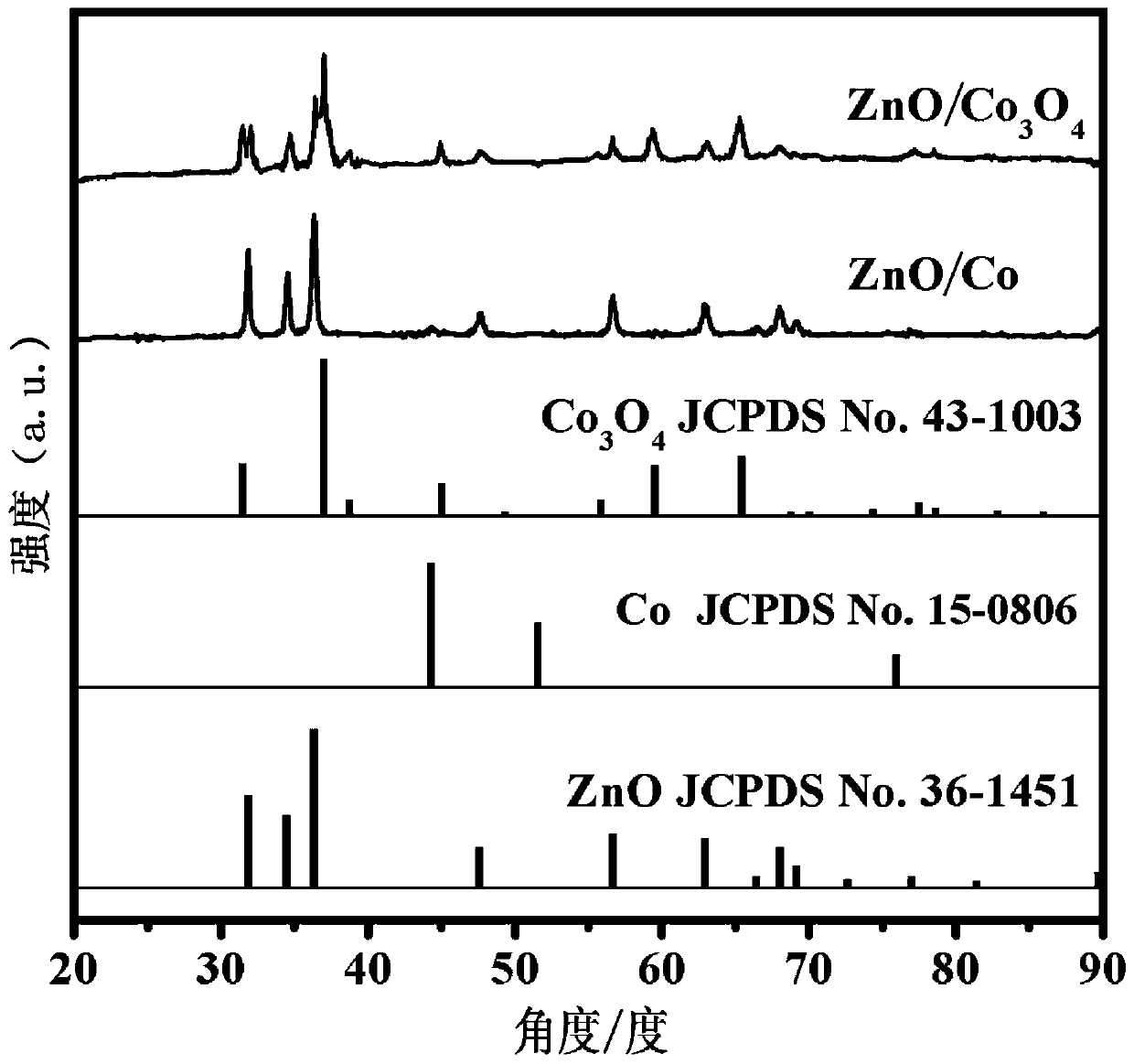

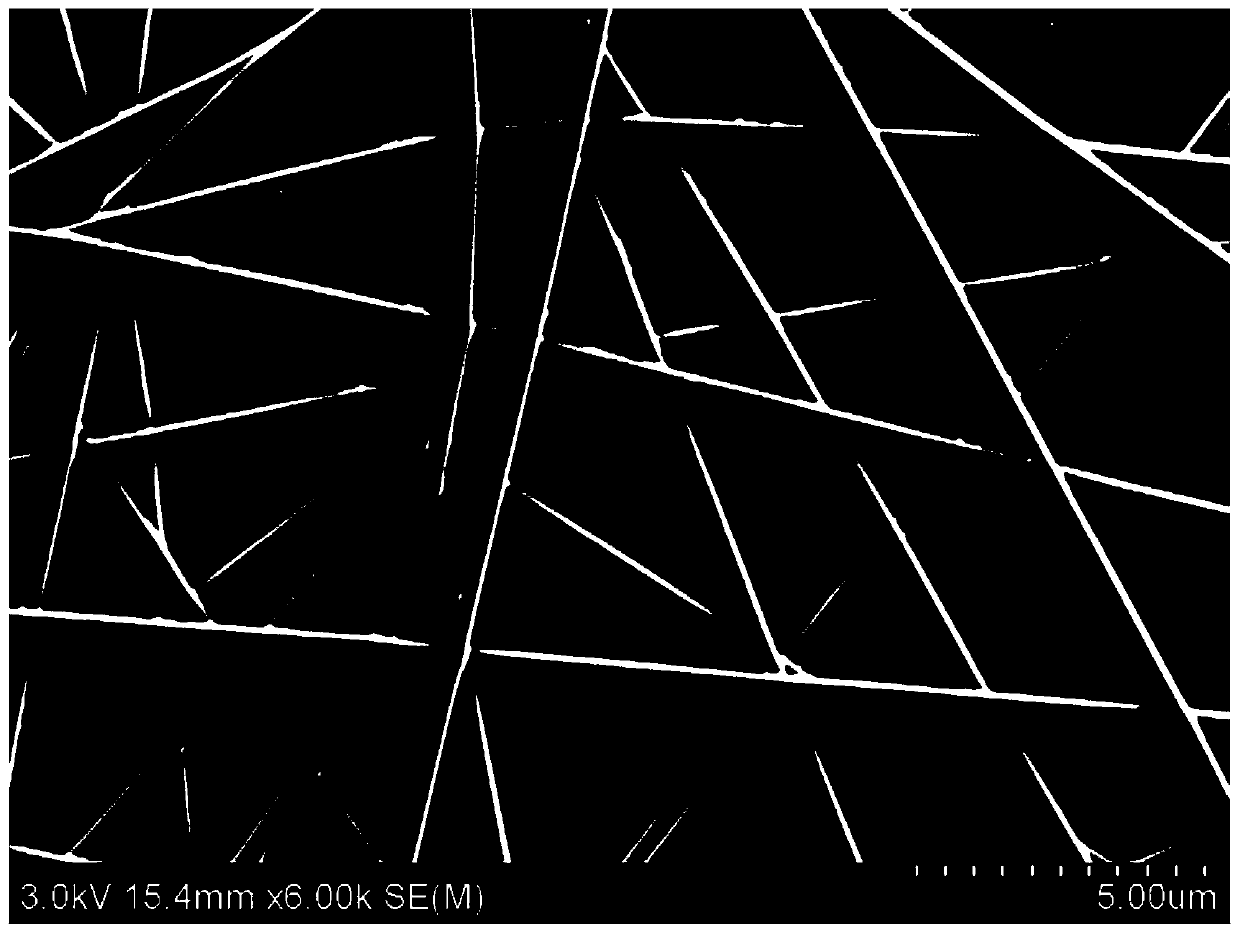

[0060] A preparation method of ZnO / Co composite nano hollow fiber electromagnetic wave absorbing material, comprising the steps of:

[0061] (1) Dissolve 1 mmol of cobalt acetylacetonate and 1 mmol of zinc acetate dihydrate in 10 ml of DMF, add 1.5 g of PVP after fully dissolving, react at 600°C for 3 hours after stirring, and obtain a uniform viscous solution;

[0062] (2) Under the condition of 12kV high-voltage static electricity, the viscous solution in step (1) is spun by a high-voltage electrospinning process to obtain organic fibers, and then the organic fibers are dried at 50°C for 20h, and then pre-oxidized at 200°C After 3 hours of treatment, place in an air atmosphere muffle furnace and calcinate at 600°C for 3 hours;

[0063] (3) Put the product calcined in step (2) in a closed tube furnace, and carry out reduction treatment at 400° C. for 1 hour in a hydrogen atmosphere to obtain a ZnO / Co composite nano hollow fiber electromagnetic wave absorbing material.

Embodiment 2

[0067] With embodiment 1, difference is: in step (1), with cobalt nitrate (Co(NO 3 ) 2 9H 2 O) instead of cobalt (II) acetylacetonate (C 10 h 14 o 4 Co). In step (2), the drying time and temperature are: 30° C., 24 hours; the time and temperature of pre-oxidation treatment are: 300° C. pre-oxidation treatment for 1 hour.

Embodiment 3

[0069] With embodiment 1, difference is: in step (1), the addition amount of described PVP is 1.0g. In step (2), the drying time and temperature are: 80° C. for 12 hours; the time and temperature for pre-oxidation treatment are: 150° C. for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com