Modified water-soluble dietary fiber thickening agent and preparation method thereof

A technology for dietary fiber and thickener, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of difficulty in degrading thickeners, complicated methods, and residues, and is suitable for large-scale production and application. Inexpensive and easy-to-get results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] As described in the background art, existing fracturing fluid thickeners and preparation methods thereof still have problems such as high cost, low degradation rate, and complicated methods. Therefore, the present invention provides a modified water-soluble dietary fiber thickener and The preparation method of the present invention will now be further described in conjunction with specific embodiments.

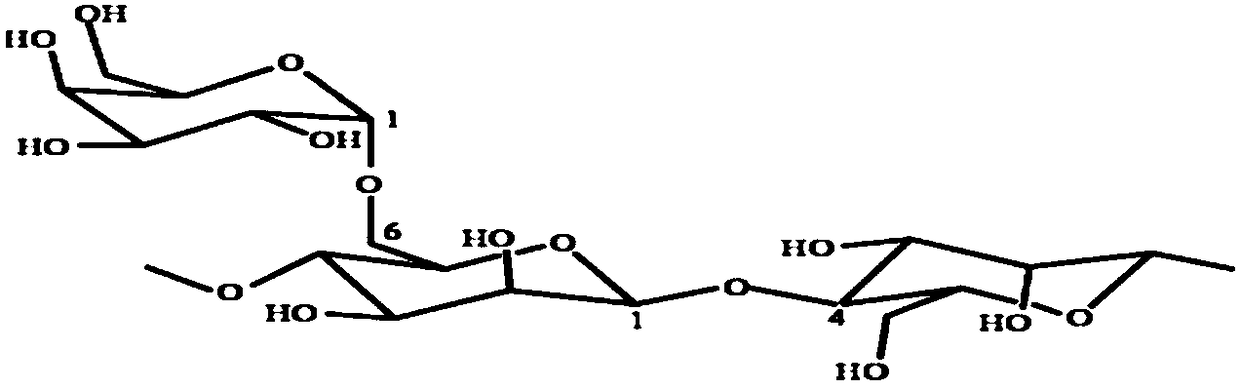

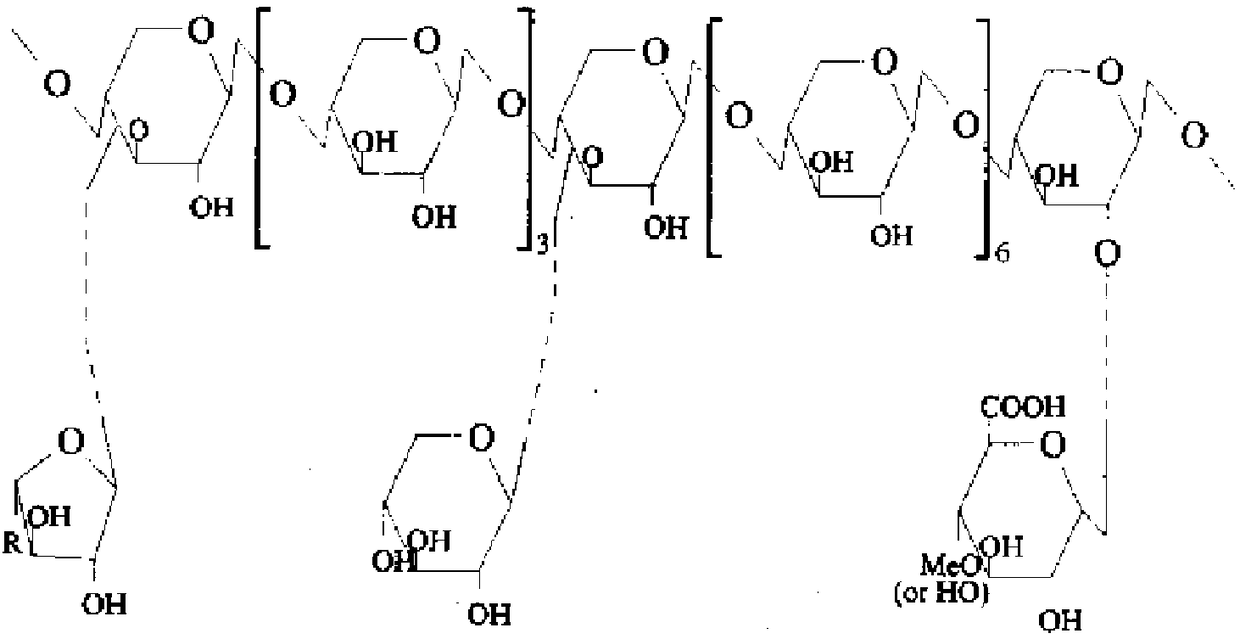

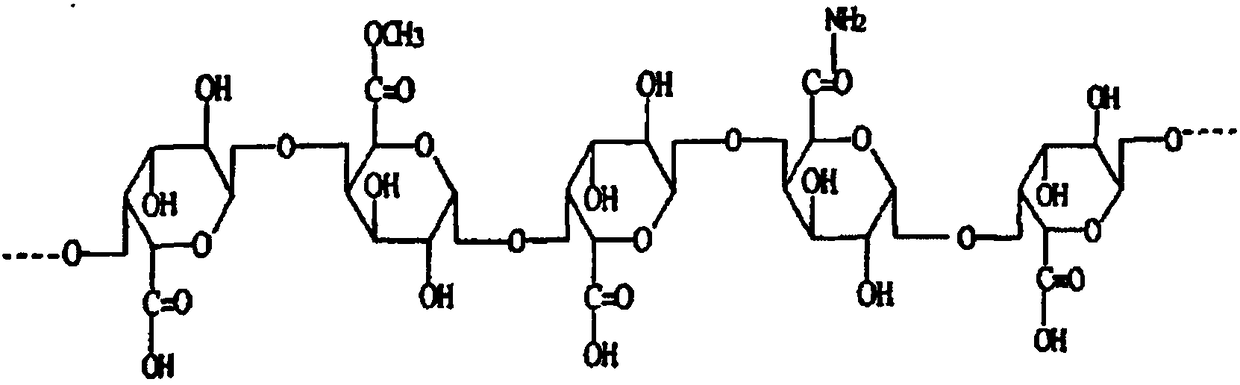

[0051] For the water-soluble dietary fiber extracted from soybean dregs in the embodiment of the present invention, see the enterprise standard number: Q / YWST0007S-2018, http: / / www.sdfda.gov.cn In addition, other existing methods can also achieve the extraction of water-soluble dietary fiber from soybean dregs, such as "Research on Extraction of Soybean Water-soluble Dietary Fiber", Wu Hui et al., 2008; doi:10.3969 / j.issn.1673-9078.2008 04.011, technicians can choose according to their needs, and the present invention does not make specific limitations.

Embodiment 1

[0053] 1. A preparation method of a modified water-soluble dietary fiber thickener, comprising the following steps:

[0054] (1) Add 2 parts by weight of water-soluble dietary fiber and 0.02 parts by weight of xanthan gum to 40 parts by weight of deionized water, stir at 45°C, and add 1 part by weight to a mass fraction of 1% after it is completely dissolved Then heat the sodium carbonate solution to 70°C for 50 minutes, and cool to 35°C after the heat preservation is completed, centrifuge to remove the bottom separation sediment, and take the upper separation for use;

[0055] (2) Add 0.1 parts by weight of a bacterial cellulase aqueous solution with a mass fraction of 10% to the upper separation in step (1), stir, heat to 45°C for 60 minutes, cool to 35°C after completion of the heat preservation, and centrifuge, Remove the separated sediment at the bottom, and take the upper separation for use;

[0056] (3) In the upper separation of step (2), 0.002 parts by weight of formaldehyd...

Embodiment 2

[0062] 1. A preparation method of a modified water-soluble dietary fiber thickener, comprising the following steps:

[0063] (1) Add 8 parts by weight of water-soluble dietary fiber and 0.2 parts by weight of xanthan gum to 45 parts by weight of deionized water, stir at 50°C, and add 10 parts by weight to 1% after being completely dissolved Then heat the sodium carbonate solution to 75°C for 55 minutes, cool to 40°C after the heat preservation is completed, centrifuge to remove the bottom separation sediment, and take the upper layer separation for use;

[0064] (2) Add 1 part by weight of a bacterial cellulase aqueous solution with a mass fraction of 10% to the upper separation in step (1), stir, heat to 50°C for 65 minutes, cool to 40°C after completion of the heat preservation, and centrifuge, Remove the separated sediment at the bottom, and take the upper separation for use;

[0065] (3) Add 0.02 parts by weight of formaldehyde and 5 parts by weight of anionic polyacrylamide wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com