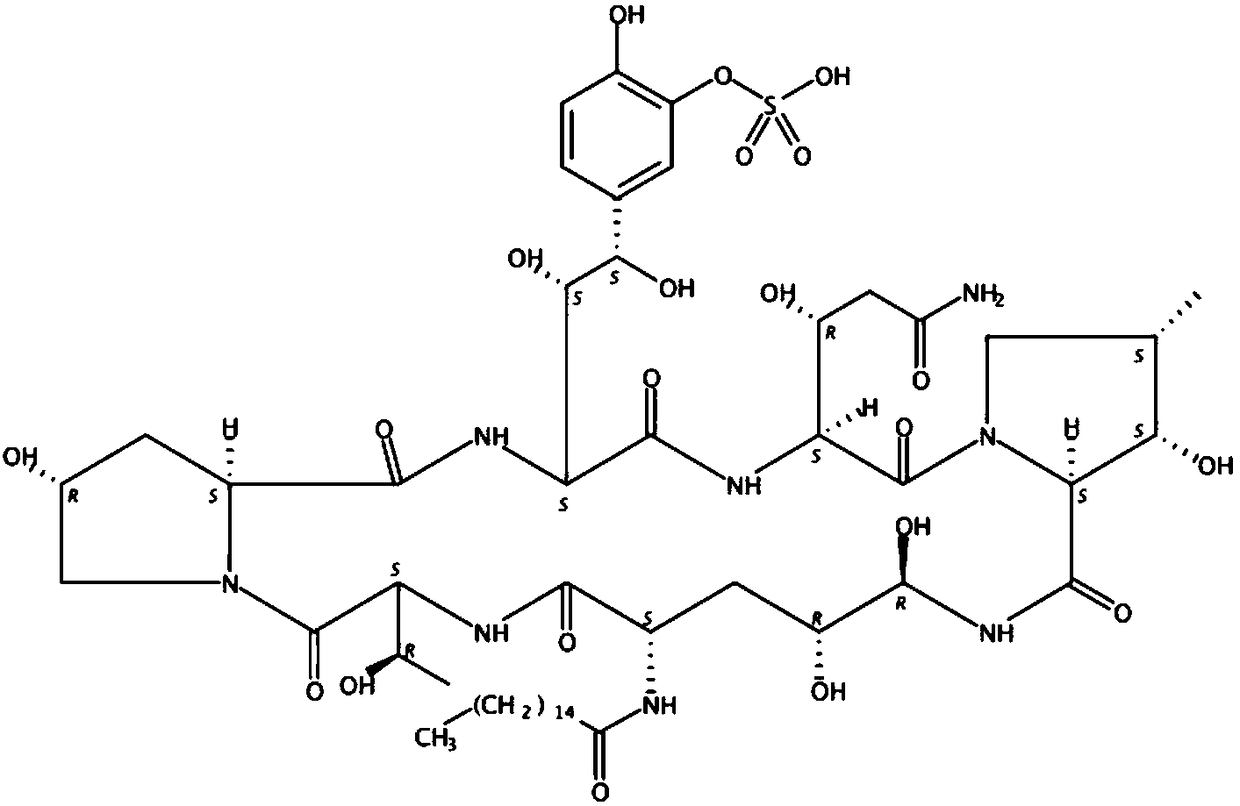

Fermentation method of micafungin sodium intermediate FR901379

A fermentation method and fermentation liquid technology, applied in the field of microbial fermentation, can solve the problems of reducing production costs, insufficient dissolved oxygen, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Transfer the cultured seeds to 30L fermentation medium at 120°C for 30 minutes and cool to 24-26°C at a ratio of 5% (v / v). The composition of the fermentation medium is mass (g) / volume (L ) ratio is: glucose 50, cottonseed cake powder 20, yeast powder 10, peptone 10, magnesium sulfate 2, dipotassium hydrogen phosphate 1, calcium carbonate 4, defoamer 1, and the rest is water.

[0020] During the fermentation process, the temperature is controlled at 24-26°C, the ventilation rate is 1VVM, and the initial rotation speed is 150rpm. During the process, the rotation speed is adjusted between 150-600rpm so that the dissolved oxygen is not lower than 20%.

[0021] Methyl palmitate and simethicone are formulated into a solution according to the mass volume ratio of simethicone at 10% and sterilized at 120° C. for 30 minutes before use.

[0022] After 48 hours of fermentation, a mixture of methyl palmitate and simethicone was added to the fermentation broth at a mass volume rati...

Embodiment 2

[0025] Transfer the cultured seeds to 30L fermentation medium at 120°C for 30 minutes and cool to 24-26°C at a ratio of 5% (v / v). The composition of the fermentation medium is mass (g) / volume (L ) ratio is: glucose 50, cottonseed cake powder 20, yeast powder 10, peptone 10, magnesium sulfate 2, dipotassium hydrogen phosphate 1, calcium carbonate 4, defoamer 1, and the rest is water.

[0026] During the fermentation process, the temperature is controlled at 24-26°C, the ventilation rate is 1VVM, and the initial rotation speed is 150rpm. During the process, the rotation speed is adjusted between 150-600rpm so that the dissolved oxygen is not lower than 20%.

[0027] Methyl palmitate and simethicone are formulated into a solution according to the mass volume ratio of simethicone at 5% and sterilized at 120° C. for 30 minutes before use.

[0028] After 48 hours of fermentation and cultivation, a mixture of methyl palmitate and simethicone oil in a mass volume ratio of 10% was adde...

Embodiment 3

[0031] Transfer the cultured seeds to 30L fermentation medium at 120°C for 30 minutes and cool to 24-26°C at a ratio of 5% (v / v). The composition of the fermentation medium is mass (g) / volume (L ) ratio is: glucose 50, cottonseed cake powder 20, yeast powder 10, peptone 10, magnesium sulfate 2, dipotassium hydrogen phosphate 1, calcium carbonate 4, defoamer 1, and the rest is water.

[0032] During the fermentation process, the temperature is controlled at 24-26°C, the ventilation rate is 1VVM, and the initial rotation speed is 150rpm. During the process, the rotation speed is adjusted between 150-600rpm so that the dissolved oxygen is not lower than 20%.

[0033] Methyl palmitate and simethicone are formulated into a solution according to the mass volume ratio of simethicone at 8% and sterilized at 120° C. for 30 minutes before use.

[0034] After 48 hours of fermentation and cultivation, a mixture of methyl palmitate and simethicone in a mass volume ratio of 8% was added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com