Rare earth cobalt permanent magnet material with high working temperature and low magnetic change and preparation method

A technology of working temperature and permanent magnet materials, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of large differences in magnetic properties, and achieve small differences in magnetic properties, high operating temperature, and high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned rare earth cobalt permanent magnet material with high working temperature and low magnetic change specifically includes the following steps:

[0038] [1] Preparation of alloy ingot:

[0039] Ingredients: component A alloy weighs the raw materials of samarium, cobalt, copper, iron and zirconium according to the mass fraction percentage of component A; weighs the raw materials of HRE, cobalt, copper, iron and zirconium according to the mass fraction percentage of component B; raw material.

[0040] Intermediate frequency induction argon protection melting alloy: put the prepared raw materials into the crucible of intermediate frequency induction furnace; vacuumize to better than 0.80×10 -2 Pa; then fill the melting furnace with argon until the pressure in the furnace is 0.05MPa-0.08MPa; gradually increase the heating power until the raw materials are melted to boiling; keep boiling for 1-3 minutes; stop heating and keep it for ...

Embodiment 1

[0053] A component composition: u=0.11, v=0.19, w=0.028, Z=6.7

[0054] B component composition: u'=0.11, v'=0.19, w'=0.028, Z'=7.0

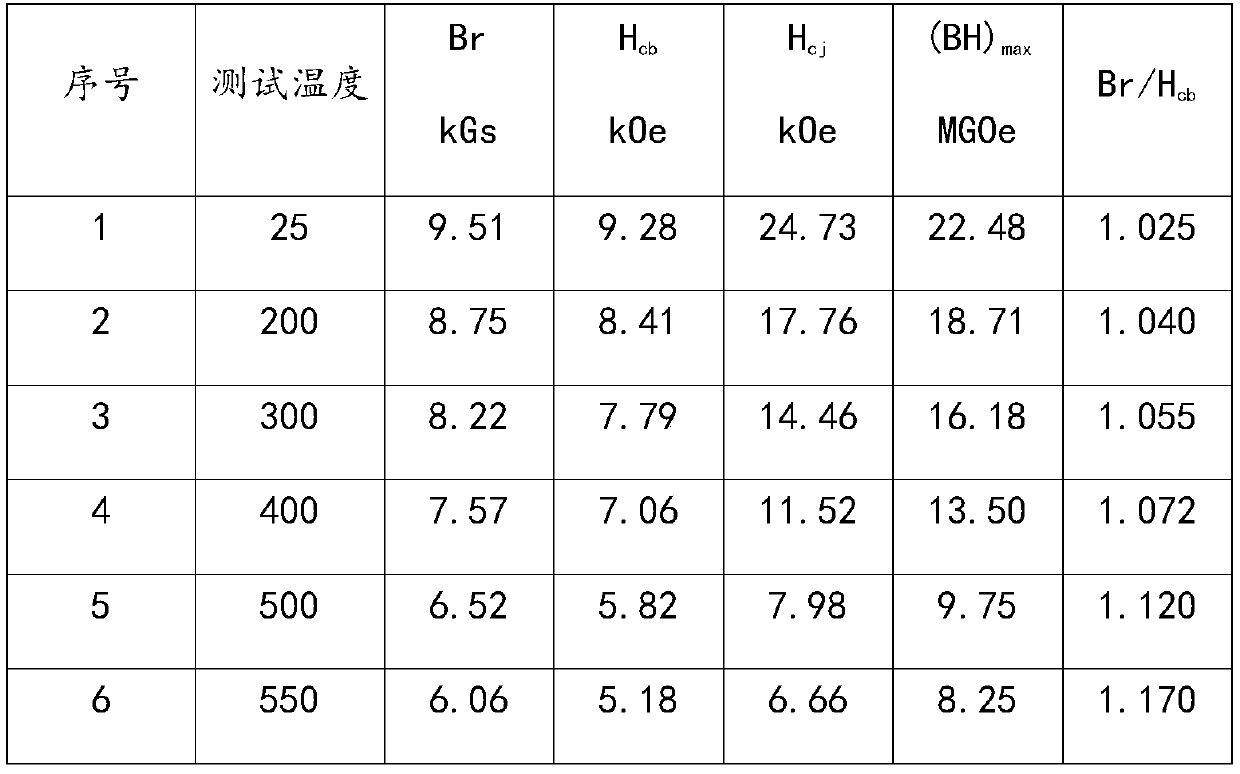

[0055] The components A and B are subjected to intermediate frequency smelting respectively to prepare material blanks. When making powder, pass through a 20-mesh sieve, the mixed mass percentage of the two components is 100% of component A, 0% of component B, the orientation magnetic field is about 960kA / m, the sintering temperature is 1205°C, the holding time is 1h, solid melting The temperature is 1170°C, the solid melting time is 2h, the heat treatment temperature is 820°C, and the holding time is 12h. Prepare test samples conforming to GB / T3217, the specific size is Φ10×10mm, use the "NIM-500C permanent magnet material ultra-high temperature measurement system" of the China Institute of Metrology to test the demagnetization curves of the samples at different temperatures, and the results are shown in Table 1. Br 500 / Br RT = 68.6%.

[...

Embodiment 2

[0059] A component composition: u=0.11, v=0.19, w=0.028, Z=6.7

[0060] B component composition: u'=0.11, v'=0.19, w'=0.028, Z'=7.0

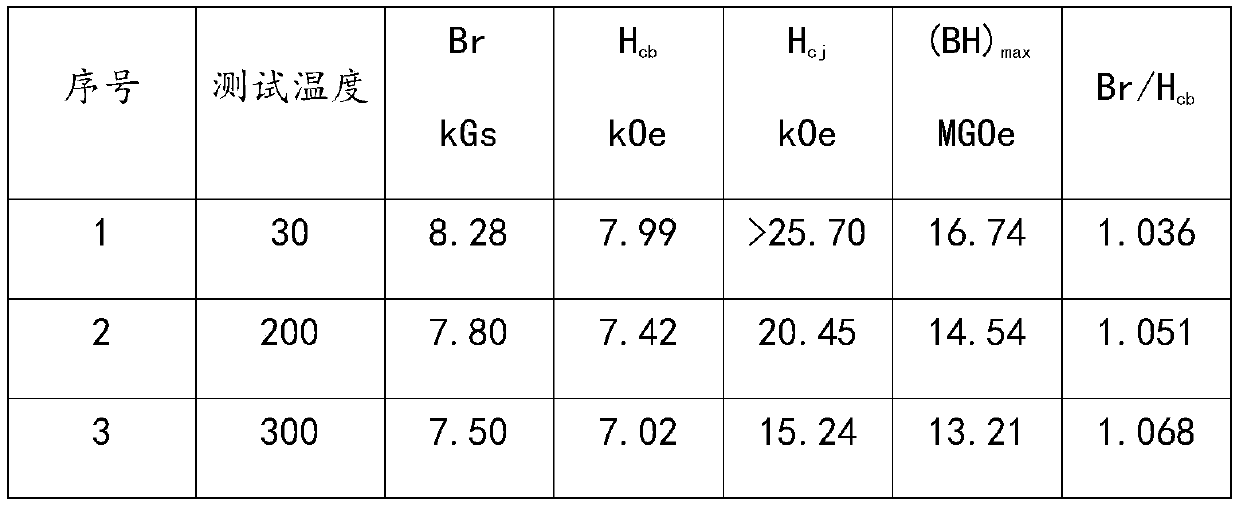

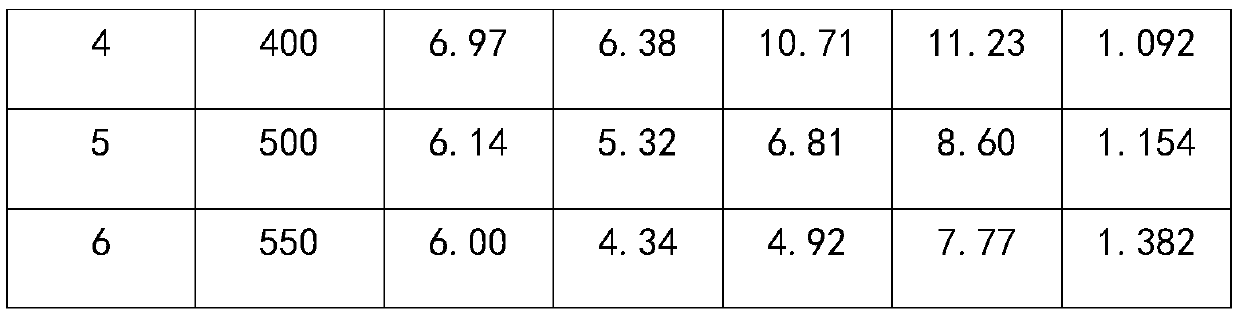

[0061] The components A and B are subjected to intermediate frequency smelting respectively to prepare material blanks. Among them, the 20-mesh sieve is passed through the powder making process, the mixed mass percentage of the two components is 70% of component A, 30% of component B, the orientation magnetic field is about 960kA / m, the sintering temperature is 1215°C, the holding time is 1h, solid melting The temperature is 1170°C, the solid melting time is 2h, the heat treatment temperature is 820°C, and the holding time is 12h. Prepare test samples conforming to GB / T3217, the specific size is Φ10×10mm, use the "NIM-500C permanent magnet material ultra-high temperature measurement system" of the China Institute of Metrology to test the demagnetization curves of the samples at different temperatures, and the results are shown in Table 2. Br ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com