Preparation method and application of super-hydrophilic/underwater super-oleophobic polyvinylidene fluoride composite membrane

An underwater super-oleophobic and polyvinylidene fluoride technology, applied in the direction of permeation/dialysis water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve the problem of limited types of oily sewage, poor chemical resistance, separation Low efficiency and other issues, to achieve the effect of low price, easy operation and control, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

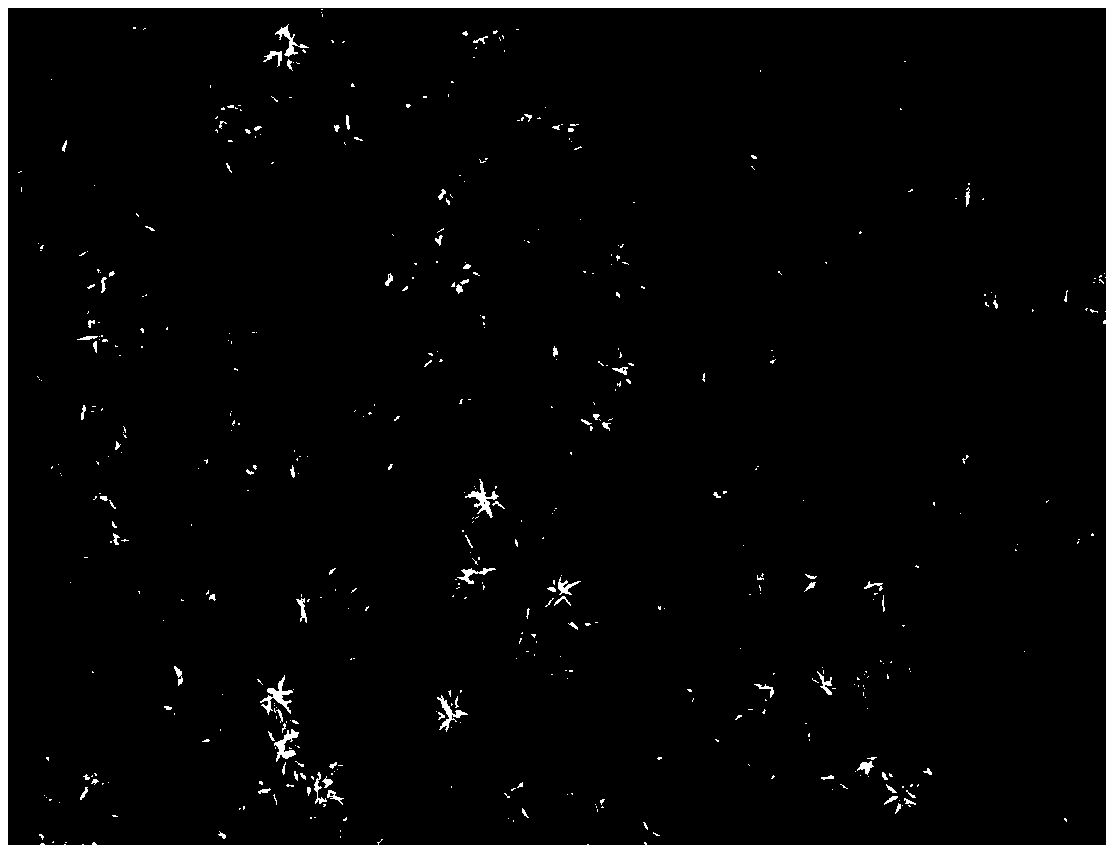

Image

Examples

Embodiment 1

[0031] (1) Preparation of PVDF membrane: Dissolve 3g of polyvinylidene fluoride powder, 1g of polyethylene glycol, and 0.1g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, stir mechanically at 50°C for 12h, and make PVDF membrane by phase inversion method.

[0032] (2) Prepare 100mL 2mg / L dopamine hydrochloride solution, sonicate it evenly, add PVDF membrane, seal and shake for 6h, take out the membrane, rinse it with deionized water, and dry it to obtain PVDF@PDA membrane.

[0033] (3) 0.3g nickel nitrate hexahydrate (Ni(NO 3 ) 2 .6H 2 O), 0.6g cobalt nitrate hexahydrate (Co(NO 3 ) 2 .6H 2 O), 0.54g of urea were dissolved in 30mL of deionized water (stirring while ultrasonic), the dissolved mixture was poured into 15mL of ethanol, and PVDF @PDA membrane was added to soak for 30 minutes, and 33mL of the mixture solution was pipetted into the reaction kettle, at 90°C After heating for 6 hours, take it out, rinse it with deionized water and ethanol, and dry it to ...

Embodiment 2

[0035] (1) Preparation of PVDF membrane: Dissolve 4.5g of polyvinylidene fluoride powder, 1.5g of polyethylene glycol, and 0.15g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, stir mechanically at 50°C for 12h, and make PVDF by phase inversion method membrane.

[0036] (2) Prepare 100mL 2mg / L dopamine hydrochloride solution, sonicate it evenly, add PVDF membrane, seal and shake for 6h, take out the membrane, rinse it with deionized water, and dry it to obtain PVDF@PDA membrane.

[0037] (3) 0.45g nickel nitrate hexahydrate (Ni(NO 3 ) 2 .6H 2 O), 0.9g cobalt nitrate hexahydrate (Co(NO 3 ) 2 .6H2 O), 0.81g of urea were dissolved in 30mL of deionized water (stirring while ultrasonic), the dissolved mixture was poured into 15mL of ethanol, and PVDF @PDA membrane was added to soak for 30 minutes, and 33mL of the mixture solution was pipetted into the reaction kettle, at 90°C After heating for 3 hours, take it out, rinse it with deionized water and ethanol, and dry i...

Embodiment 3

[0039] (1) Preparation of PVDF membrane: Dissolve 6g of polyvinylidene fluoride powder, 2g of polyethylene glycol (PEG), and 0.2g of polyvinylpyrrolidone into 30mL of N-methylpyrrolidone, stir mechanically at 50°C for 12h, and make it by phase inversion method PVDF membrane.

[0040] (2) Prepare 100mL 2mg / L dopamine hydrochloride solution, sonicate it evenly, add PVDF membrane, seal and shake for 6h, take out the membrane, rinse it with deionized water, and dry it to obtain PVDF@PDA membrane.

[0041] (3) 0.6g nickel nitrate hexahydrate (Ni(NO 3 ) 2 .6H 2 O), 1.2g cobalt nitrate hexahydrate (Co(NO 3 ) 2 .6H 2 O), 1.08g of urea were dissolved in 30mL of deionized water (stirring while ultrasonic), the dissolved mixture was poured into 15mL of ethanol, and PVDF @PDA membrane was added to soak for 30 minutes, and 33mL of the mixture solution was pipetted into the reaction kettle, at 90°C After heating for 9 hours, take it out, rinse it with deionized water and ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com