Anti-fouling and wear-resistant organic silicone coating material for ABS (Acrylonitrile Butadiene Styrene) surface and preparation method thereof

A coating material, silicone technology, applied in antifouling/underwater coatings, fire retardant coatings, coatings, etc., can solve the problems of easy deformation of ABS, poor adhesion, rare reports, etc., to improve adhesion. Focus, excellent friction resistance, improve the effect of anti-contamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

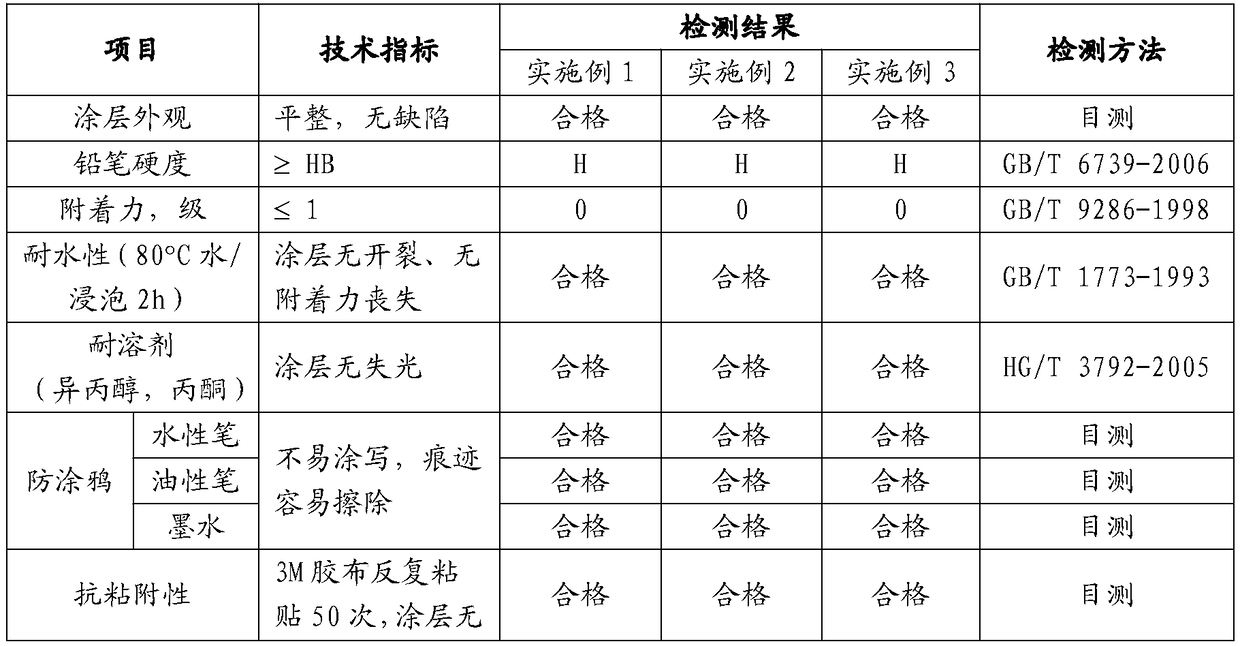

Examples

Embodiment 1

[0035] ① Prepare each component according to the following formula

[0036]Deionized 16g; acetic acid 0.2g; methyltrimethoxysilane 40g; phenyltrimethoxysilane 4g; CHG-101 hydroxy acrylic oligomer 1.5g; hydroxy silicone oil antifouling additive 0.8g; Leveling agent 0.2g; Tetramethylammonium hydroxide 0.2g; Ethylene glycol butyl ether 10g; Butyl acetate 15g;

[0037] ②In a 250mL round-bottomed flask, add deionized water and acetic acid in sequence, and after stirring evenly, slowly add the mixture of methyltrimethoxysilane and phenyltrimethoxysilane into the flask, and stir at 25°C for 2h Complete hydrolytic prepolymerization. Heated and refluxed to continue the reaction for 2.5h;

[0038] ③In the liquid material obtained in step ②, add curing accelerator, antifouling additive, wetting and leveling agent, butyl glycol ether and butyl acetate in sequence, and stir for 3 minutes to obtain antifouling and wear-resistant silicone Material (varnish).

[0039] The material obtaine...

Embodiment 2

[0041] ① Prepare each component according to the following formula

[0042] Deionized 5g; acidic silica sol 20g; acetic acid 0.2g; methyltriethoxysilane 56g; phenyltrimethoxysilane 4g; CHG-104 hydroxyacrylic oligomer 1.5g; BYK-331 wetting and leveling agent 0.2g; Guanidine hydrochloride 0.15g; Ethylene glycol butyl ether 10g; Butyl acetate 15g;

[0043] ②In a 250mL round-bottomed flask, add deionized water and acetic acid in sequence, and after stirring evenly, slowly add the mixture of methyltriethoxysilane and phenyltrimethoxysilane into the flask, and stir the reaction at 25°C 2h to complete the hydrolysis pre-polymerization. Heated and refluxed to continue the reaction for 2.5h;

[0044] ③In the liquid material obtained in step ②, add curing accelerator, antifouling additive, wetting and leveling agent, butyl glycol ether and butyl acetate in sequence, and stir for 3 minutes to obtain antifouling and wear-resistant silicone Material (varnish).

[0045] The material obt...

Embodiment 3

[0047] ① Prepare each component according to the following formula

[0048] 26g of acidic silica sol; 0.2g of acetic acid; 52g of methyltrimethoxysilane; 6g of phenyltrimethoxysilane; 2g of CHG-101 hydroxyl acrylic oligomer; Leveling agent 0.2g; Tetramethylammonium hydroxide 0.2g; Ethylene glycol butyl ether 10g; Butyl acetate 15g; Pearlescent mica 0.4g

[0049] ②In a 250mL round-bottomed flask, add deionized water and acetic acid in sequence, and after stirring evenly, slowly add the mixture of methyltrimethoxysilane and phenyltrimethoxysilane into the flask, and stir at 25°C for 2h Complete hydrolytic prepolymerization. Heated and refluxed to continue the reaction for 2.5h;

[0050] ③In the liquid material obtained in step ②, add curing accelerator, antifouling additive, wetting and leveling agent, butyl glycol ether and butyl acetate in sequence, and stir for 3 minutes. Add pearlescent mica and stir evenly to obtain a shiny Effect ABS antifouling, wear-resistant silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com