Integration device of rotational-flow liquid separation, rotational-flow desulfurization and rotational-flow alkaline control of low-pressure separated gas in hydrogenation device and implementation method thereof

A technology of hydrogenation device and low gas separation is applied in the field of low separation gas cyclone liquid separation-cyclone desulfurization-cyclone alkali control integrated device, which can solve the problem of equipment cost, large land occupation investment, complicated equipment and low separation efficiency. problems, to achieve the effect of reducing equipment footprint, convenient operation and maintenance, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

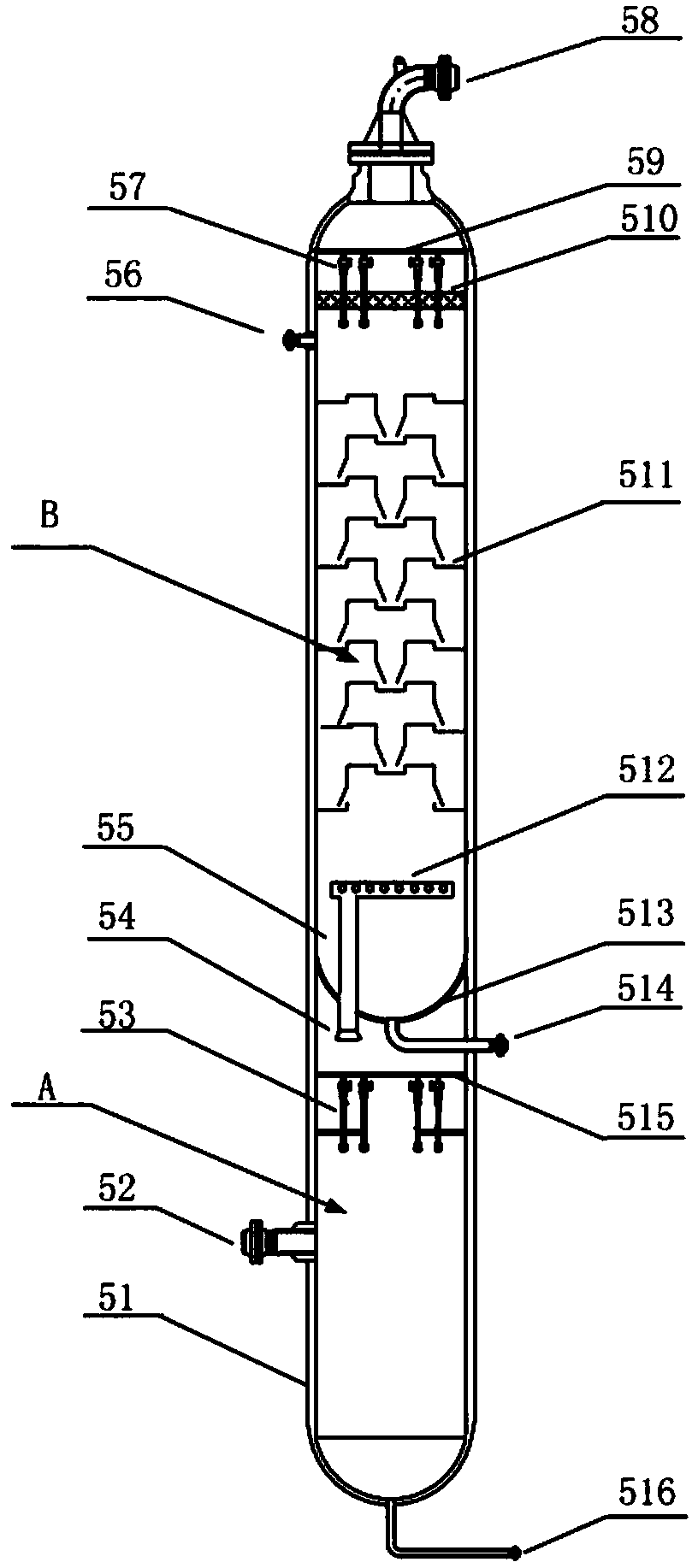

[0053] In the second aspect of the present disclosure, a method for implementing a low-volume cyclone liquid separation-cyclone desulfurization-cyclone alkali control integrated device in a hydrogenation unit is provided, the method includes the following steps:

[0054] (a) Cyclone separation and dehydrocarbon operation of low gas fraction: the mixed gas from the cold low-pressure separator enters the gas-liquid phase of the integrated device of cyclone liquid separation-cyclone desulfurization-cyclone alkali control into the gas-liquid phase of the device The separation section A is distributed into the micro-swirl dehydrogenation tube group to implement gas-liquid separation operation; under the action of centrifugal force, the liquid droplets flow out from the bottom outlet of the micro-swirl flow dehydrogenation tube group and settle to the bottom from the low oil separation outlet to discharge the device. After dehydrogenation, the low fraction gas flows out from the over...

Embodiment 1

[0068] The hydrogenation and upgrading of diesel oil is carried out by using the integrated device of low fraction cyclone flow liquid separation-swirl flow desulfurization-swirl flow alkali control in the hydrogenation unit of the present invention.

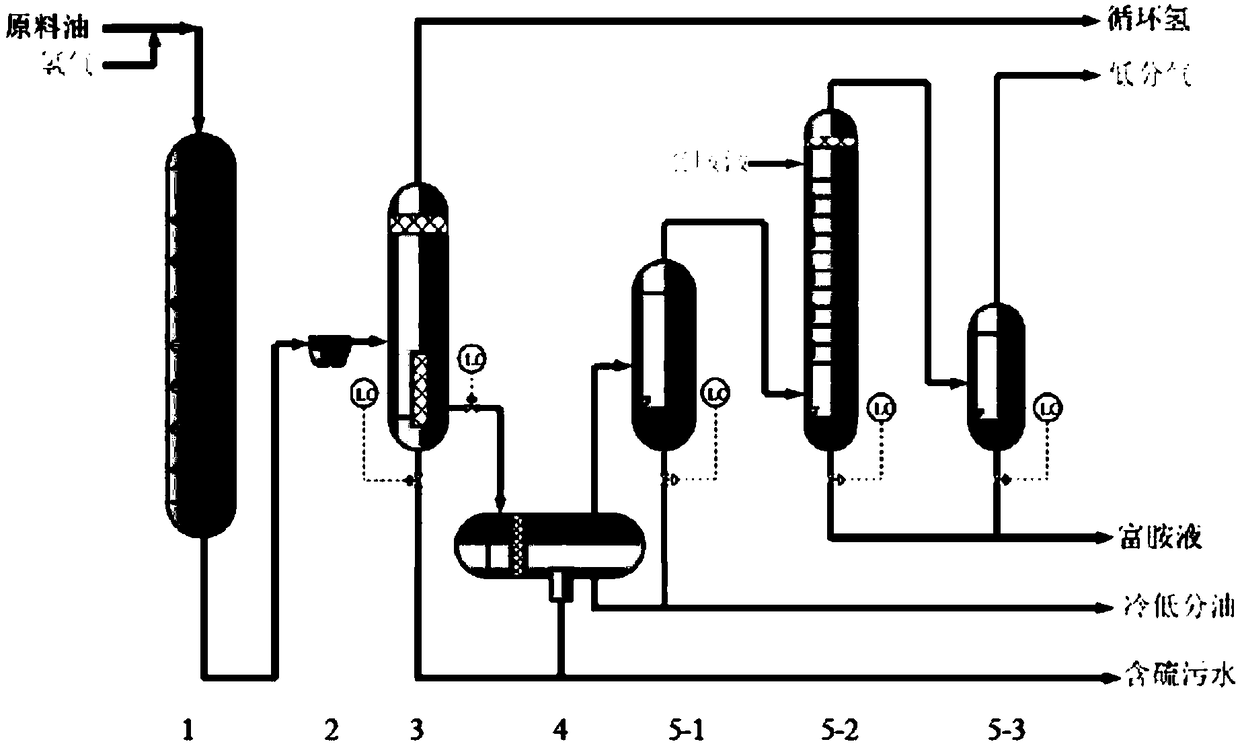

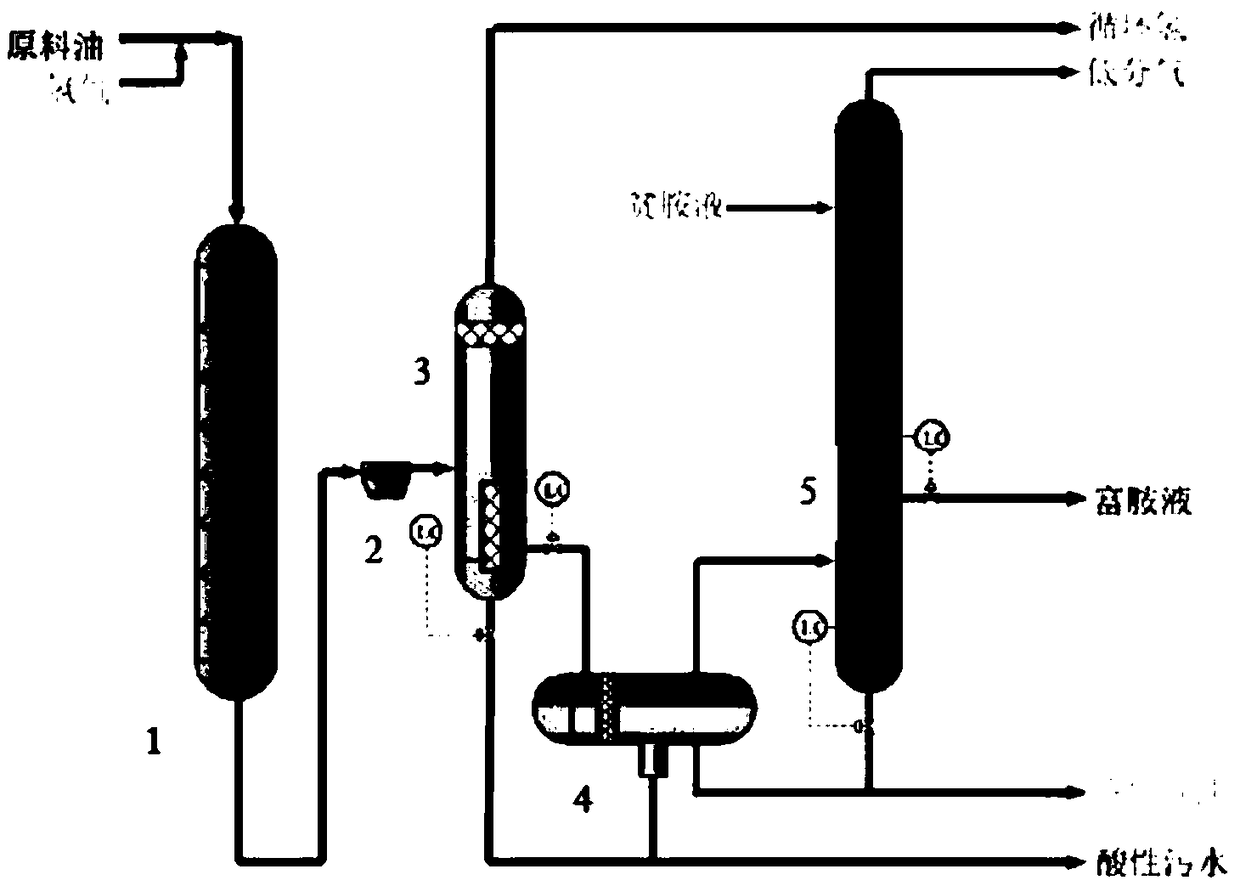

[0069] (1) Process flow

[0070] like Figure 2-3 shown.

[0071] (2) Device parameters

[0072] See Table 1 below.

[0073] Integrated device design parameters in Table 1 Embodiment 1

[0074] project

Gas-liquid separation section A

Desulfurization and alkali control section B

Nominal diameter, mm

1200

1200

Tangent height, mm

3600

19400

pressure, MPa

2.1

2.1

temperature, ℃

50

50

main medium

h 2 、H 2 S, hydrocarbon droplets

h 2 、H 2 S and amine liquid droplets

[0075] (3) Material parameters

[0076] See Table 2 below.

[0077] Material parameter in the embodiment 1 of table 2

[0078]

[0079] (4) Implementation effect

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com