High-performance CuNiSiTiBMg-series elastic copper alloy and preparation method thereof

An elastic copper alloy, high-performance technology, applied in the field of elastic alloy and its preparation, can solve the problems of difficulty in realization, insufficient plasticity, low plasticity requirements, etc., and achieve improved stress relaxation resistance, enhanced grain boundary strengthening, and tensile strength increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

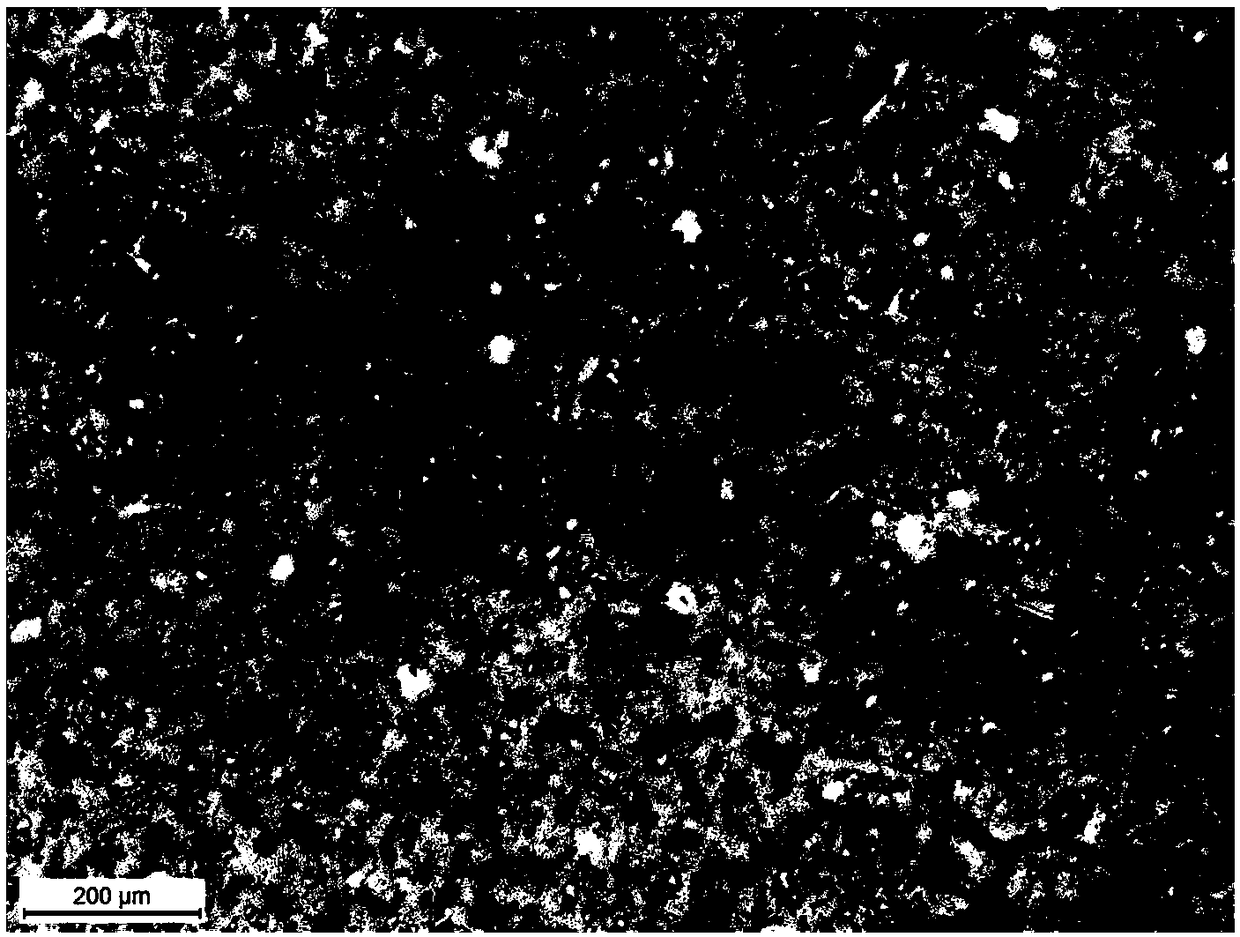

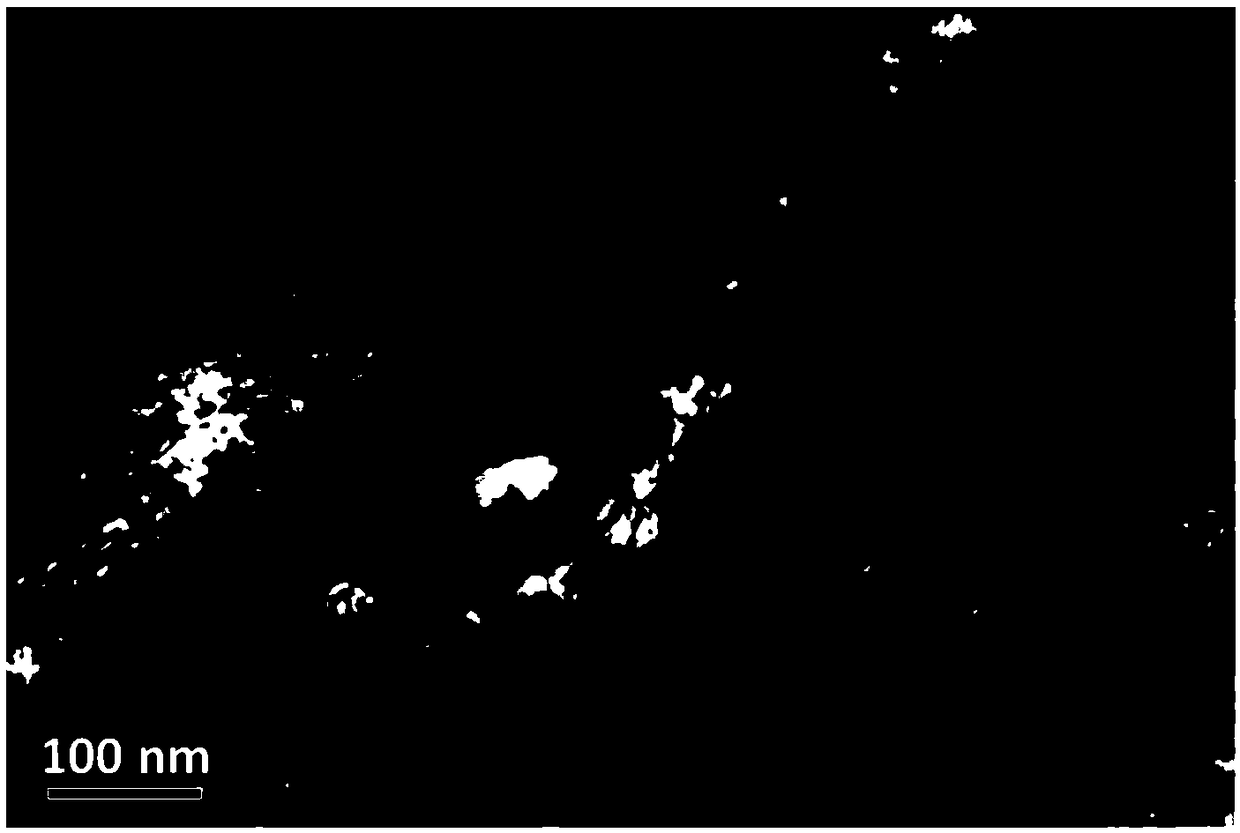

Image

Examples

Embodiment 1

[0040] A high-performance CuNiSiTiBMg-based elastic copper alloy of the present invention, in weight percent, the high-performance CuNiSiTiBMg-based elastic copper alloy contains the following components: Ni 8.0%, Si 2.0%, Ti 1.0%, B0.1%, Mg 0.2%, the rest is Cu and unavoidable impurities.

[0041] The preparation method of the high-performance CuNiSiTiBMg system elastic copper alloy of the present embodiment comprises the following steps:

[0042] (1) Prepare materials according to the weight percentage of the constituent elements in the high-performance CuNiSiTiBMg-based elastic copper alloy. Put electrolytic copper, electrolytic nickel, electrolytic silicon and electrolytic titanium into a heating furnace for melting at a melting temperature of 1250 ° C. After they are completely melted , lower the temperature to 1250°C, then add pure magnesium, and form an alloy melt after melting;

[0043] (2) The alloy melt is continuously cast into a slab on a continuous casting machin...

Embodiment 2

[0052] A high-performance CuNiSiTiBMg-based elastic copper alloy of the present invention, in weight percent, the high-performance CuNiSiTiBMg-based elastic copper alloy contains the following components: Ni 8.2%, Si 2.2%, Ti 1.2%, B0.3%, Mg 0.24%, the rest is Cu and unavoidable impurities.

[0053] The preparation method of the high-performance CuNiSiTiBMg system elastic copper alloy of the present embodiment comprises the following steps:

[0054] (1) Prepare materials according to the weight percentage of the constituent elements in the high-performance CuNiSiTiBMg-based elastic copper alloy. Put electrolytic copper, electrolytic nickel, electrolytic silicon and electrolytic titanium into a heating furnace for melting at a melting temperature of 1250 ° C. After they are completely melted , lower the temperature to 1250°C, then add copper-boron intermediate alloy and pure magnesium, and form an alloy melt after melting;

[0055] (2) The alloy melt is continuously cast into ...

Embodiment 3

[0064] A high-performance CuNiSiTiBMg-based elastic copper alloy of the present invention, in weight percent, the high-performance CuNiSiTiBMg-based elastic copper alloy contains the following components: Ni 8.8%, Si 2.1%, Ti 1.0%, B0.1%, Mg 0.25%, the rest is Cu and unavoidable impurities.

[0065] The preparation method of the high-performance CuNiSiTiBMg system elastic copper alloy of the present embodiment comprises the following steps:

[0066] (1) Prepare materials according to the weight percentage of the constituent elements in the high-performance CuNiSiTiBMg-based elastic copper alloy. Put electrolytic copper, electrolytic nickel, electrolytic silicon and electrolytic titanium into a heating furnace for melting at a melting temperature of 1250 ° C. After they are completely melted , lower the temperature to 1200°C, then add copper-boron intermediate alloy and pure magnesium, and form an alloy melt after melting;

[0067] (2) The alloy melt is continuously cast into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com