Microstrip patch antenna based on SIW resonant cavity loading

A microstrip patch antenna, resonant cavity technology, applied in the direction of the antenna grounding switch structure connection, waveguide, circuit, etc., can solve the problems of reduced antenna radiation efficiency, complex structure design, high manufacturing cost, and achieve wide bandwidth and good radiation characteristics. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

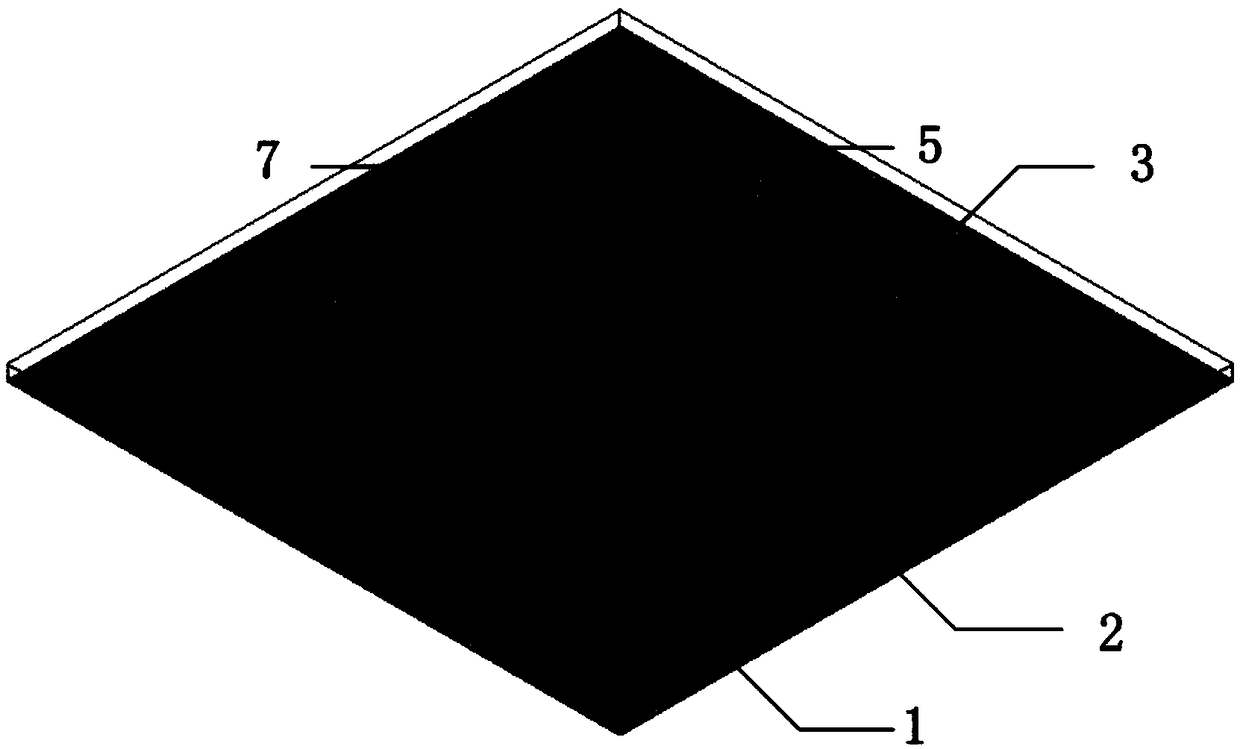

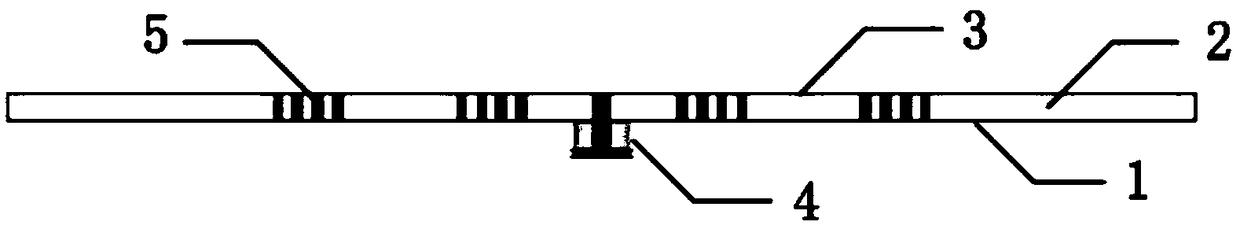

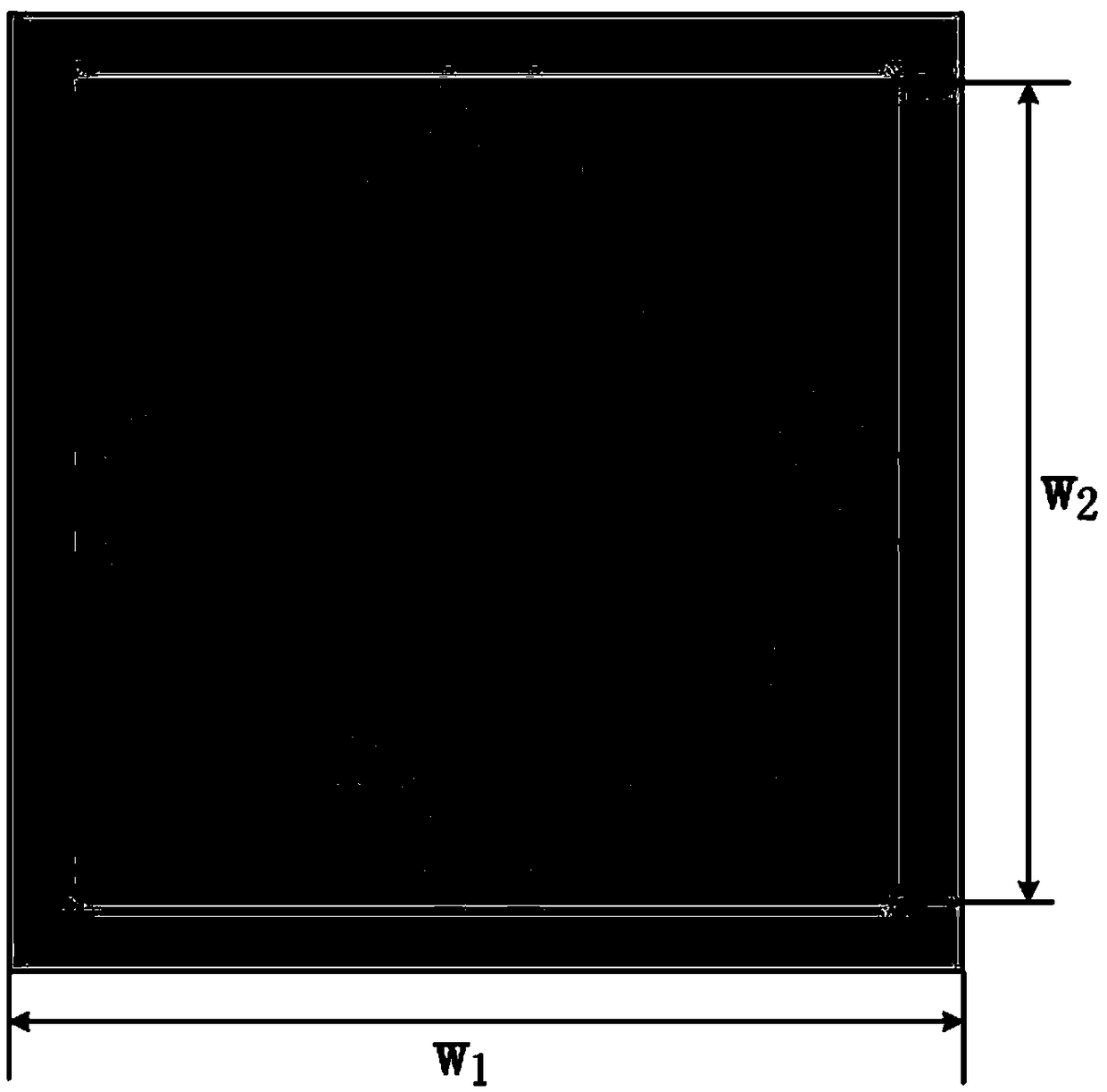

[0032] Such as figure 2 As shown, a microstrip patch antenna based on SIW resonant cavity loading includes a metal formation layer 1, a dielectric substrate 2, a square patch layer 3 and an SMA coaxial excitation input port 4 stacked from bottom to top. The dielectric substrate 2 is provided with a metallized through-hole array 5, and the metallized through-hole array 5 together with the square patch layer 3 and the metal ground layer 1 forms a square substrate integrated waveguide SIW cavity 7, and the metallized through-hole array 5 That is, the four sides of the square substrate integrated waveguide cavity 7, the square substrate integrated waveguide cavity 7 and the square patch layer 3 share a center point, and the angular displacement between the two is 45°, the square substrate integrated waveguide cavity 7 There are coupling windows 6 of the same size in the middle of the four sides.

[0033] Such as image 3 As shown, this embodiment is based on the simulation mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com