Nanocomposite Zn2TiO4 functional material and preparation method of dispersion liquid thereof

A nano-composite and functional material technology, applied in the field of preparation of nano-oxide materials, can solve problems such as easy saturation of adsorption materials, achieve high-concentration preparation, increase uniformity, and maintain long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

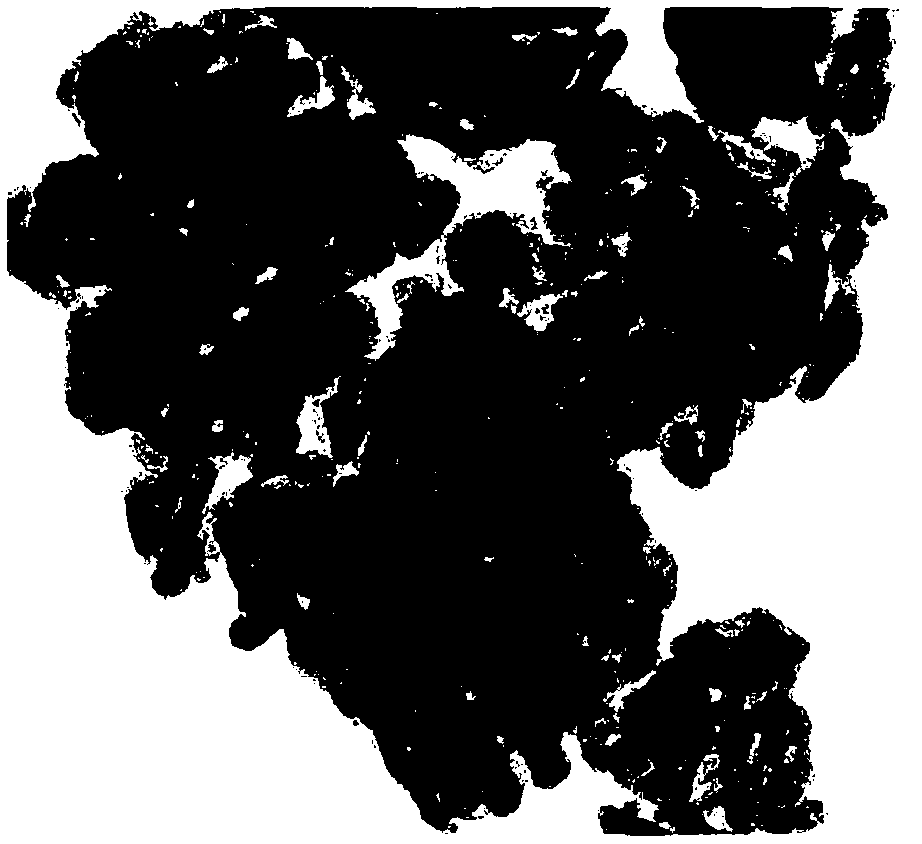

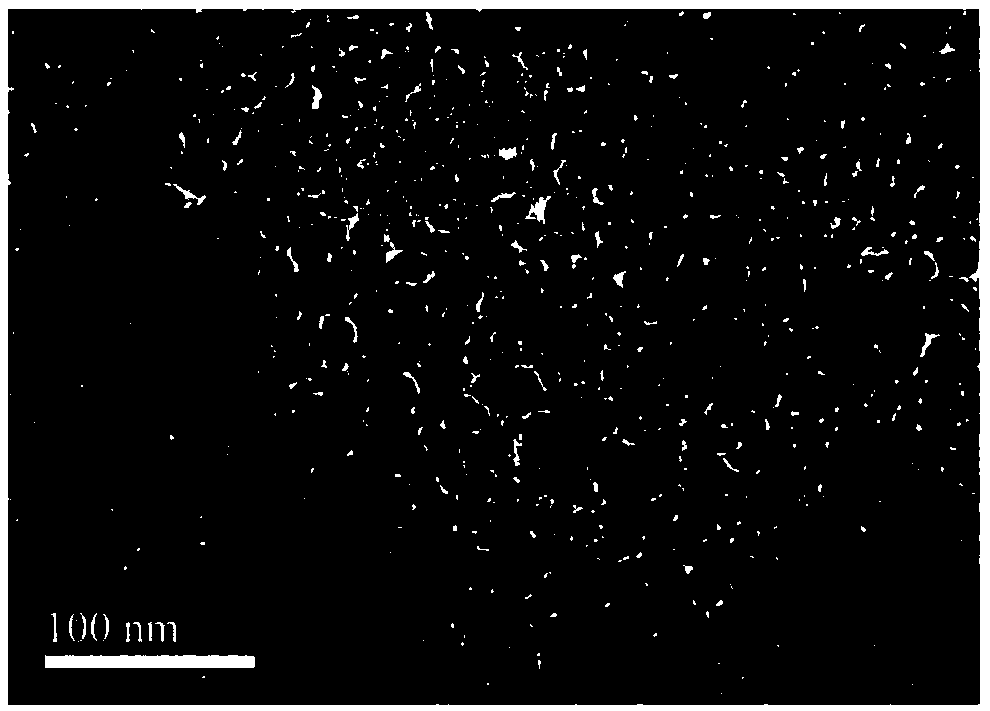

[0023] Example 1: Premix 300 ml of ethanol and 30 ml of water to form a mixed solvent, then add 6 ml of HNO 3 As an inhibitor of the follow-up reaction; Zn and Ti compounds, weighed 22.32g of zinc nitrate and 10.66g of tetraisopropyl titanate according to the molar ratio of 2:1, added to the previous alcohol-water-acid mixture, passed Stir with a magnetic heating stirrer until it is completely dissolved; then add 10.72 g of ethylenediaminetetraacetic acid and 3.52 g of citric acid into the pre-mixed metal ion solution, mix well, add ammonia water dropwise to adjust the pH value to 7, and continue stirring ; After the above mixed solution is stirred evenly into a sol, then 80 o C heating and stirring until gel state, then at 200 oC Dried in the blast oven for 6 hours to obtain a black fluffy precursor; put the precursor into the muffle furnace for 300 o C,1 oC / min heating rate and calcined for 5 hours to obtain white Zn 2 TiO 4 (ZnO-TiO 2 ) composite powder; take 1 gZn...

Embodiment 2

[0024] Example 2: Premix 300 ml ethanol and 90 ml water to form a mixed solvent, then add 15 ml of HNO 3 As an inhibitor of the follow-up reaction; Zn and Ti compounds, weigh 10.41g of zinc chloride and 13g of tetra-n-butyl titanate according to the molar ratio of 2:1, join in the previous alcohol-water-acid mixture, pass Stir with a magnetic heating stirrer until it is completely dissolved; then add 15.3 g of lauric acid and 7.3 g of nitrilotriacetic acid into the premixed metal ion solution, mix well, add ammonia water dropwise to adjust the pH to 7.5, and continue stirring; After the above mixed solution was stirred evenly to form a sol, then 80 o C heating and stirring until gel state, then at 250 oC Dried in the blast oven for 12 hours to obtain a black fluffy precursor; put the precursor into the muffle furnace for 400 o C, 5 oC / min heating rate calcined for 10 hours to obtain white Zn 2 TiO 4 (ZnO-TiO 2 ) composite powder; take 10 g Zn 2 TiO 4 Composite powde...

Embodiment 3

[0025] Example 3: Premix 300 ml of ethanol and 150 ml of water to form a mixed solvent, then add 21 ml of HNO 3 As an inhibitor of subsequent reactions; Zn and Ti compounds, according to the molar ratio of 2:1, weigh 15.1g of dimethyl zinc and 15g of titanium tetrachloride, and add them to the previous alcohol-water-acid mixture. Heat the stirrer and stir until it is completely dissolved; then add 124.41 g of diethylenetriaminepentaacetic acid and 30.38 g of citric acid into the pre-mixed metal ion solution, mix well and add ammonia water dropwise to adjust the pH value to 8. Continue to stir; after the above mixed solution is stirred evenly into a sol, then 80 o C heating and stirring until gel state, then at 300 oC Dried in the blast oven for 24 hours to obtain a black fluffy precursor; put the precursor into the muffle furnace for 500 o C, 10 oC / min heating rate calcined for 15 hours to obtain white Zn 2 TiO 4 (ZnO-TiO 2 ) composite powder; take 30 gZn 2 TiO 4 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com