A kind of integrated catalytic conversion method for biomass furfural compounds in ethanol

A catalytic conversion method and compound technology, applied in the field of integrated catalytic conversion of biomass furfural compounds in ethanol, can solve the problem of low selectivity of acetaldehyde stability target products, and achieve good industrial application potential, atom economy and The effect of high mass conversion rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0034] Coupling of hydrogen transfer reactions and intersecthyde condensation reactions: 0.48 g (5 mmol) furfural is dissolved in 2.30 g (50 mmol) ethanol, adding a catalyst, forming a sealed reaction vessel, microwave radiation for 4 hours, and the reaction temperature is 140 ° C . The catalyst is divided into the following four: 200 mg Zr-Beta zeolite molecular sieve, add 25 mg of potassium carbonate, and add 200 mg of Zr-Beta zeolite molecular sieve and add 25 mg of potassium carbonate, no catalyst. The reaction results are shown in Table 1.

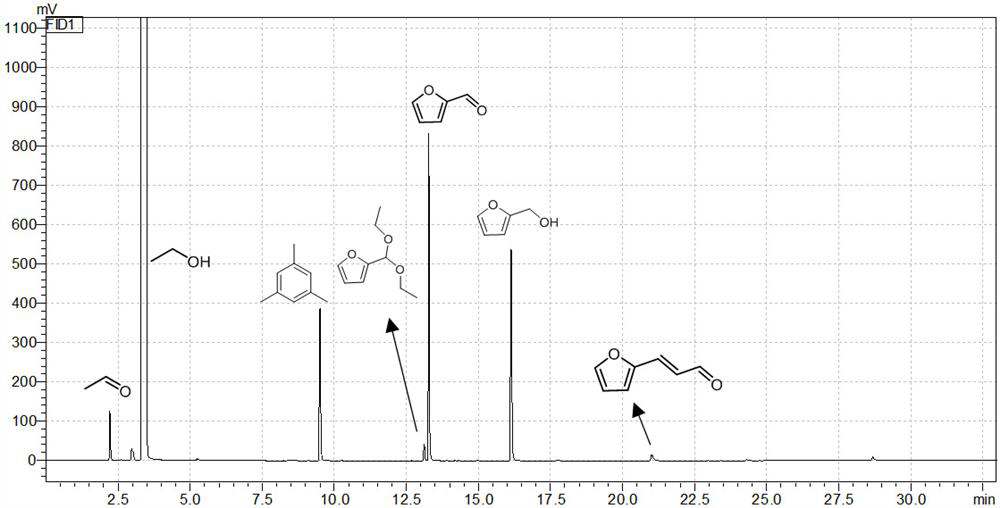

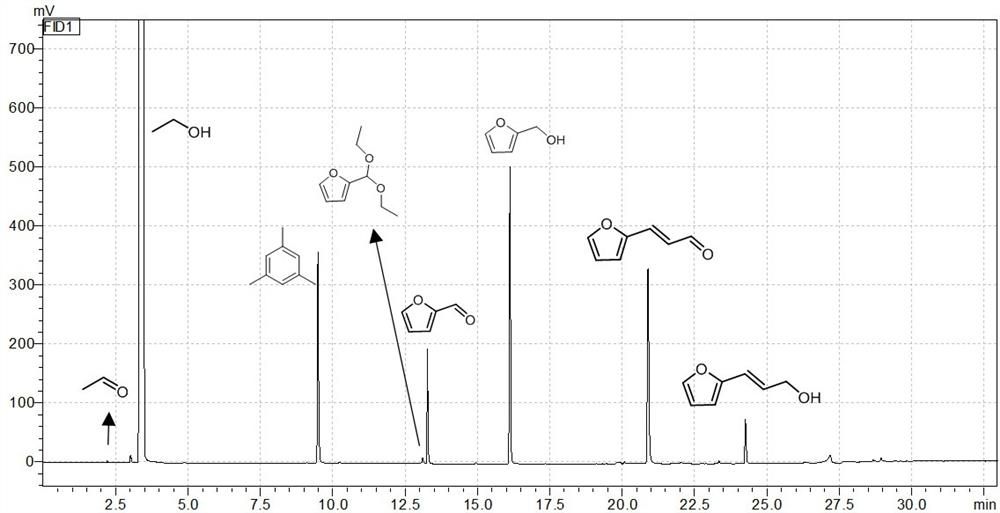

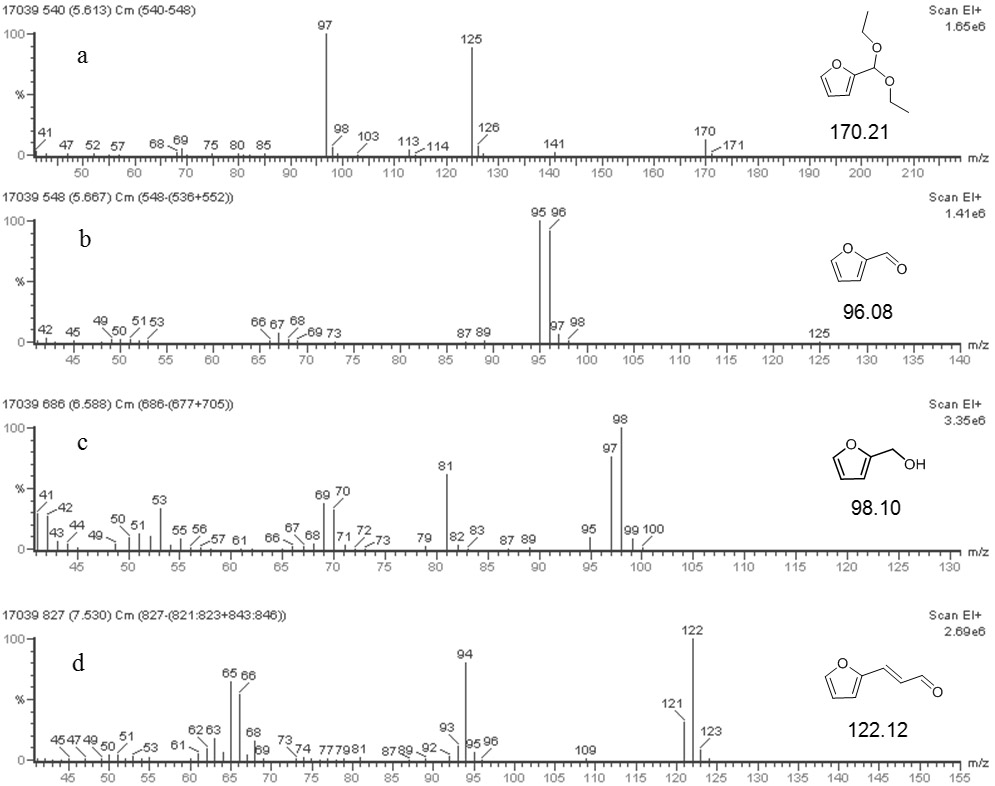

[0035] As can be seen from Table 1, the Zr-Beta zeolite molecular sieve can catalyze the hydrogen transfer reaction between furfural and ethanol, the main product obtained is a furfury and acetaldehyde, and the gas phase chromatogram of the product is seen. figure 1 . In the case of simultaneous addition of Zr-beta zeolite molecular sieve and potassium carbonate, two products having similar yields can be obtained, and the gas phase chroma...

Embodiment 5

[0039] Experiments were carried out using methods similar to Example 2, but Zr-beta was changed to HF-BETA zeolite molecular sieve to obtain a similar furfural conversion and product yield.

Embodiment 6

[0041] Experiments were carried out using the method similar to Example 2, but the 200 mg Zr-Beta zeolite molecular sieves were used to 250 mg of zirconia to obtain a similar furfural conversion and product yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com