Method for co-production of 1,3-propanediol and glutamic acid through recombined corynebacterium glutamicum

A technology of Corynebacterium glutamicum and propylene glycol, applied in microorganism-based methods, biochemical equipment and methods, bacteria and other directions, can solve the problems of low glucose quality yield, complicated post-extraction process, low yield and the like, and achieve separation Process simplification, resolution of biosafety, effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

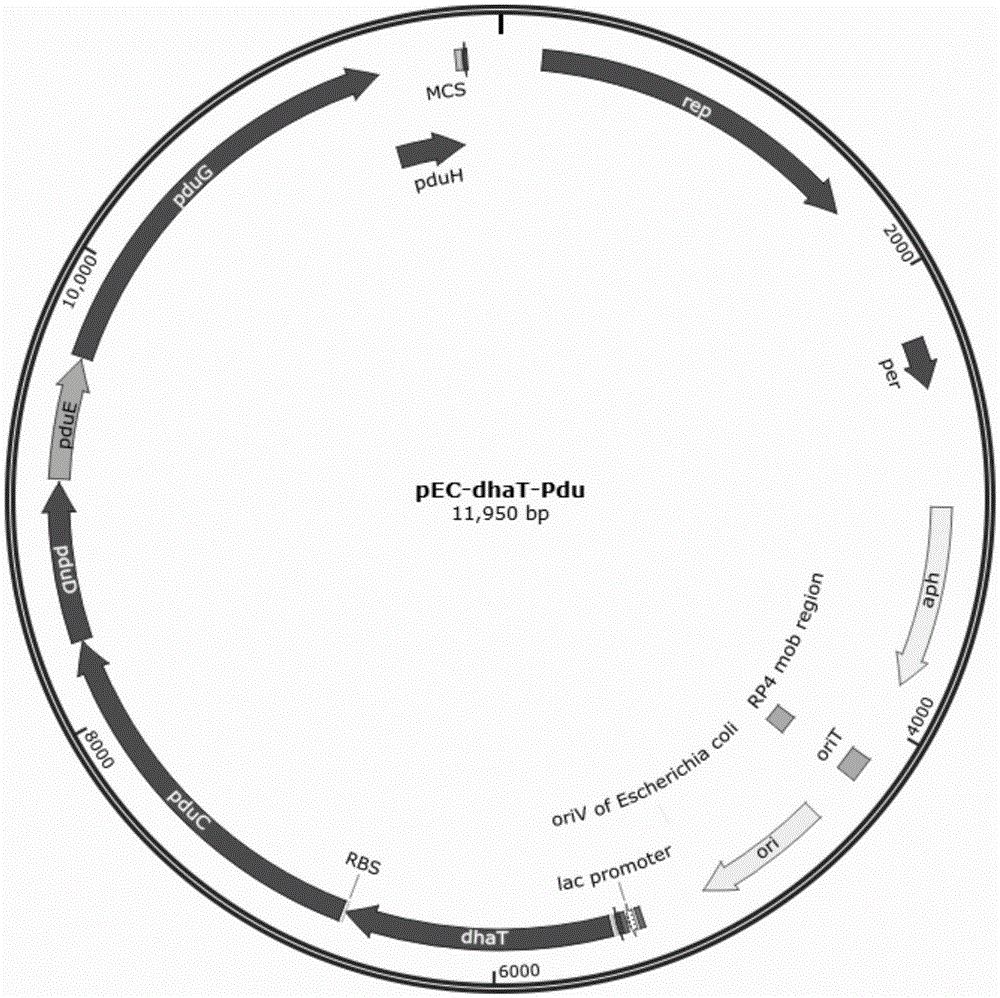

[0030] The recombinant plasmid pEC-dhaT-pdu overexpressing 1,2-propanediol dehydratase and its activator and 1,3-propanediol dehydrogenase gene was constructed.

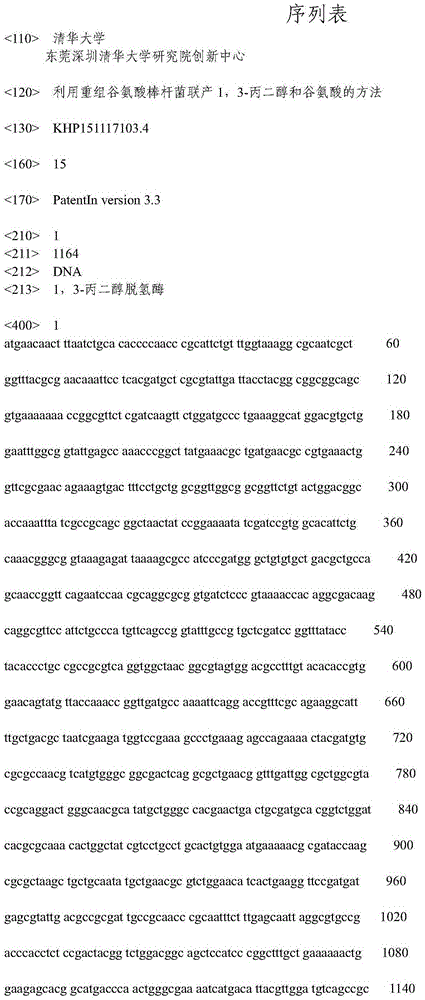

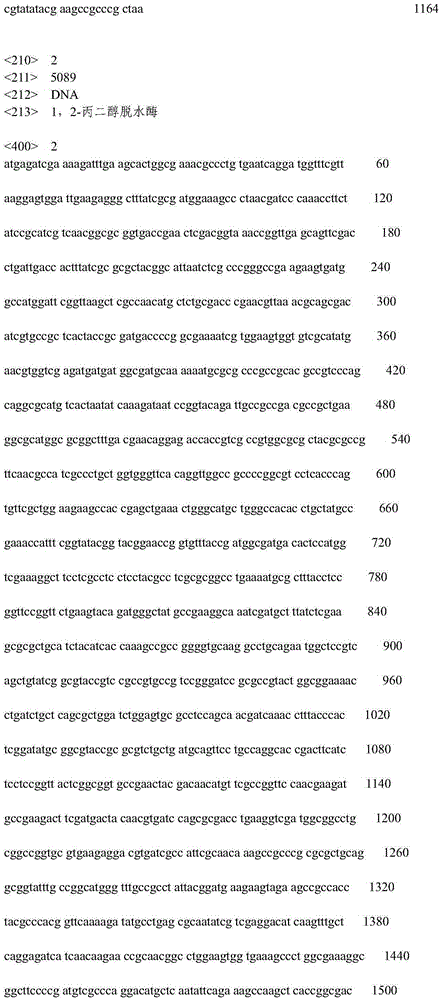

[0031] The genome of Klebsiella pneumoniae HR526 was used as a template, and the primers pdu-F (tgcctgcaggtcgactctagTTAAGCATGGCGATCCCGAAATGG) and pdu-R (CGCCCGCtaaAAGGAGATATACCATGAGATCGAAAAGATTTGAAG) were used as primers for PCR to obtain the pduCDEGH operon including 1,2-propanediol dehydratase and its activator Fragment (pduCDEGH sequence shown in SEQ ID NO.2) and PCR product purification (Tiangen biological PCR product purification kit). Using the genome of Klebsiella pneumoniae HR526 as a template, primers dhaT-F (ATATCTCTTttaGCGGGCGGCTTCGTATA) and dhaT-R (ctatgacatgattacgaattAAGGAGATATACCatgAACAACTTTAATCTGCAC) were used as primers to carry out PCR to obtain 1,3-propanediol dehydrogenase gene dhaT fragment (sequence as SEQ ID NO. 1) and purified (Tiangen Biological PCR Product Purification Kit). The Escherichia ...

Embodiment 2

[0033] Knockout of the lactate dehydrogenase gene ldhA.

[0034]Using the genome of Corynebacterium glutamicum ATCC13032 as a template, PCR was carried out with primers ldhA-up-F (ctatgacatgattacgaattAAAACAGCCAGGTTAGCAGCC) and ldhA-up-R (CGCCAAAGATTTTCGATCCCACTTCCTGATTTCCC) to obtain a homologous fragment ldhA-up about 500 bp upstream of ldhA and carry out PCR product purification. Using the genome of Corynebacterium glutamicum ATCC13032 as a template, PCR was performed with primers ldhA-down-F (GGGATCGAAAATCTTTGGCGCCTAGTTGGC) and ldhA-up-R (ccgggtaccgagctcgaattGAGAATTTCGGCGTGCTCG) as primers, and a homologous fragment ldhA-down about 500 bp downstream of ldhA was obtained and carried out PCR product purification. Corynebacterium glutamicum suicide plasmid pK18mobsacB (JournalofBiotechnology 104 (2003) 287-299) was single-digested with EcoRI, and the ldhA-up and ldhA-down fragments were connected to pK18mobsacB in one step using GibsonAssembly kit (NEB) to obtain The recombi...

Embodiment 3

[0036] Construction of recombinant Corynebacterium glutamicum expressing 1,2-propanediol dehydratase and its activator and 1,3-propanediol dehydrogenase gene.

[0037] Using an electroporation instrument (Bio-Rad), pEC-dhaT-pdu was transformed into the wild strain of Corynebacterium glutamicum ATCC13032 and the recombinant strain C. glutamicumΔldhA knocked out of lactate dehydrogenase ldhA by electroporation. The electric shock condition was a voltage of 2.5KV, The resistance is 600Ω, and the capacitance is 25μF (the width of the shock cup is 2mm). The recombinant strains were screened on LB plate containing 25mg / L kanamycin, and named as C.glutamicum / pEC-dhaT-pdu and C.glutamicumΔldhA / pEC-dhaT-pdu respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com