Preparation method of glyphosate and triclopyr aqueous solution

A clopyroxy acetic acid aqueous solution, a technology of clopyroxy acetic acid, which is applied in the fields of botany equipment and methods, herbicides and algicides, chemical instruments and methods, etc., and can solve the problem of not being easy to control the active ingredient content of the composition , proportion, water agent stability can not be guaranteed, complex process operation and other issues, to achieve stable quality, reduce treatment costs, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

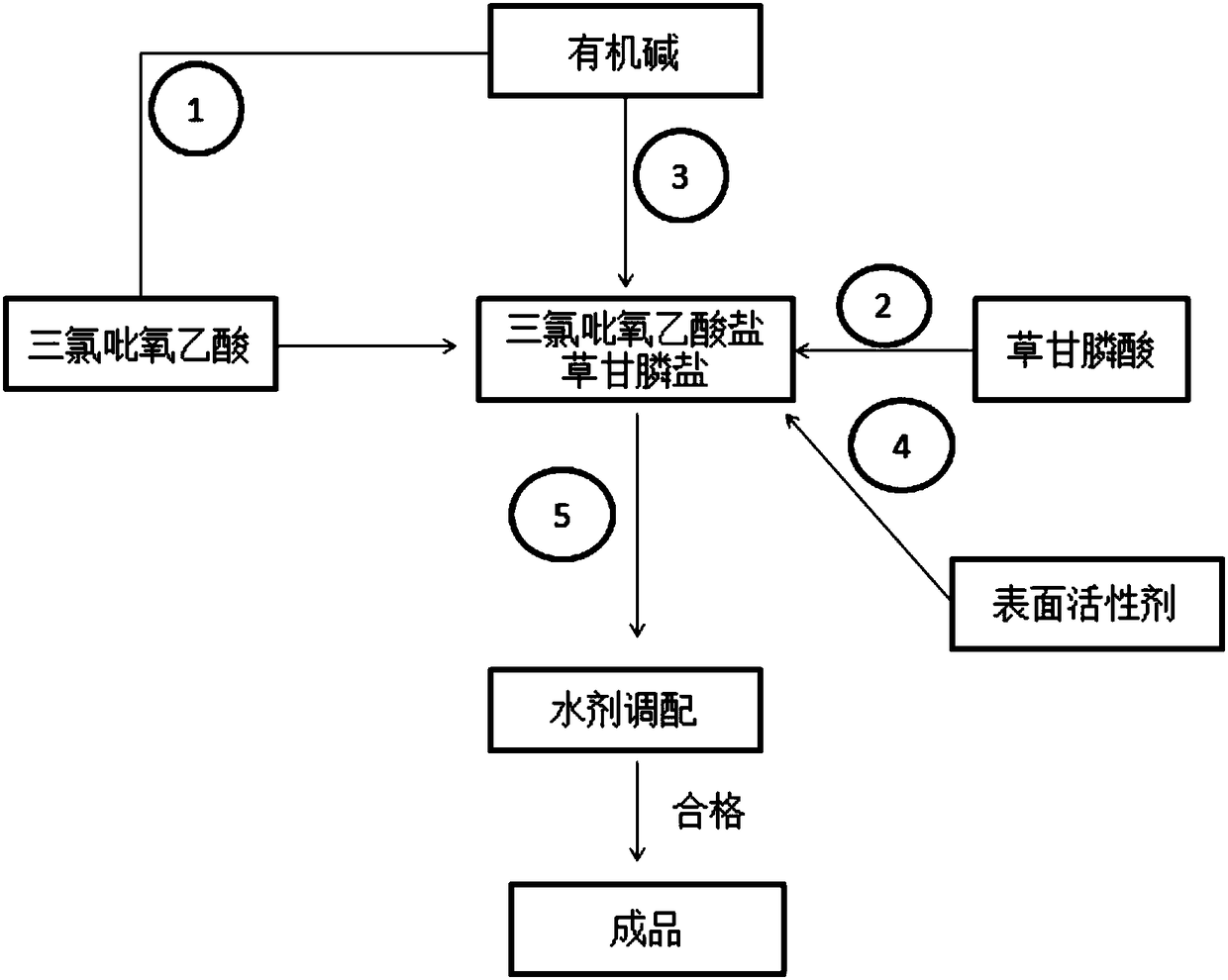

Method used

Image

Examples

Embodiment 1

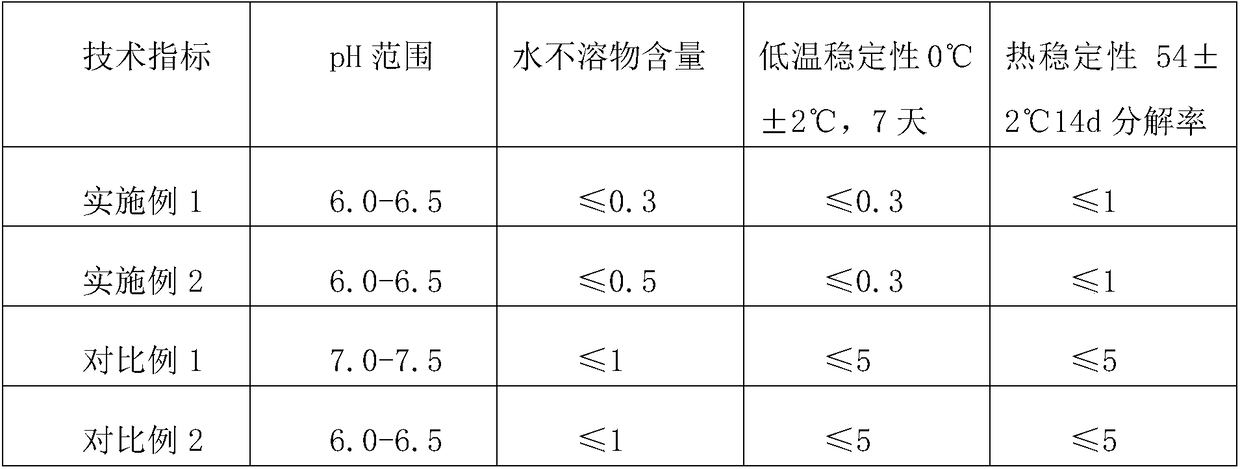

[0037] Example 1: 45% glyphosate triethylamine·triclopyr triethylamine aqueous solution (prepared in laboratory).

[0038] According to the needs of the reaction, weigh 40% glyphosate (calculated as acid), 5% triclopyr, 10% alkylphenol polyoxyethylene ether, 1% silicone defoamer, and cosolvent ammonium sulfate 2%, the rest is water.

[0039] First add triclopyr in the reaction device, start stirring, then slowly add triethylamine dropwise, the reaction temperature is 70 ℃, until the solution is colorless to light yellow clear and transparent liquid, the reaction stops when the pH is about 8.0; Then add glyphosate acid, stir well and slowly add triethylamine, the pH value of the whole system is controlled at about 6.0-6.5, the solution is light yellow to yellow transparent liquid, there is no solid particles, and finally the cosolvent ammonium sulfate is added. Surfactant alkylphenol polyoxyethylene ether and defoamer silicone are obtained when the preparation is a light yellow to ...

Embodiment 2

[0040] Example 2: 45% glyphosate triethylamine·triclopyr triethylamine aqueous solution (prepared by pilot experiment)

[0041] The raw materials are the same as in Example 1, except that the preparation process is scaled up.

[0042] The pilot production of glyphosate triethylamine·triclopyroxyacetic acid triethylamine aqueous solution includes material preparation, dosing of the original drug, salt formation reaction, supplementary additives, dissolution cycle, filtration cycle, central control analysis, filtration storage, Product packaging, finished product analysis, and collection and treatment of the three wastes required for environmental protection.

[0043] 1) Material preparation

[0044] Go to the warehouse 1-2 days in advance to collect the raw materials needed for the batch of production.

[0045] 2) Add the original medicine

[0046] Close the bottom valve, manhole cover and all pipeline valves on the reactor (except the vent valve), open the soft water pipeline valve, and...

Embodiment 3

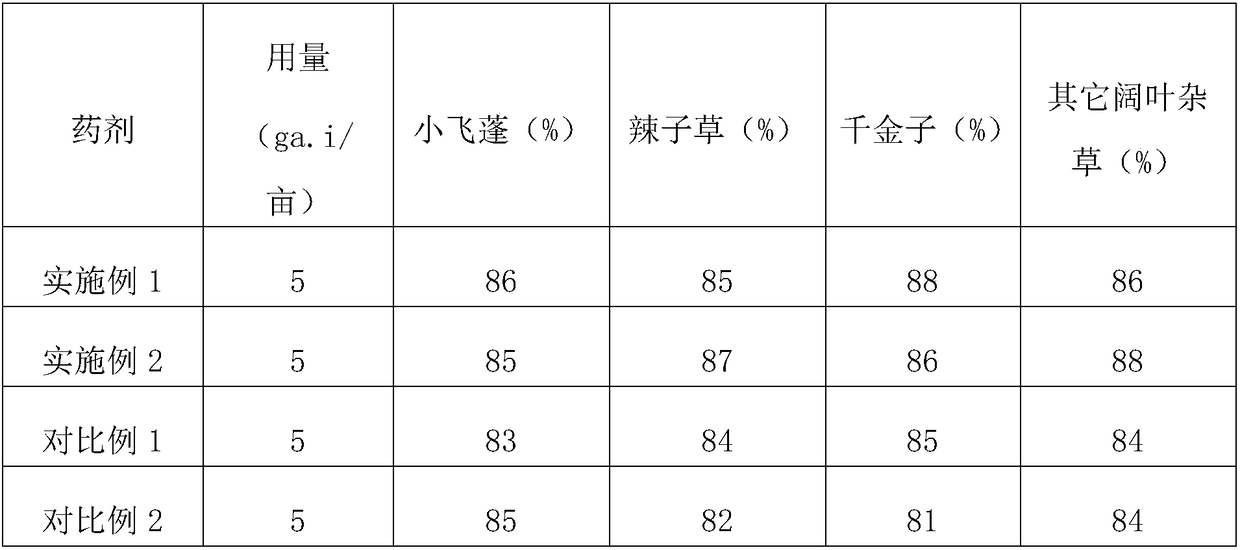

[0069] Example 3: Field efficacy test

[0070] Test agent: the water agent of Example 1-2, Comparative Example 1-2.

[0071] Control agent: 46% glyphosate isopropylamine saline (control agent 1), 45% triclopyr in water (control agent 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com