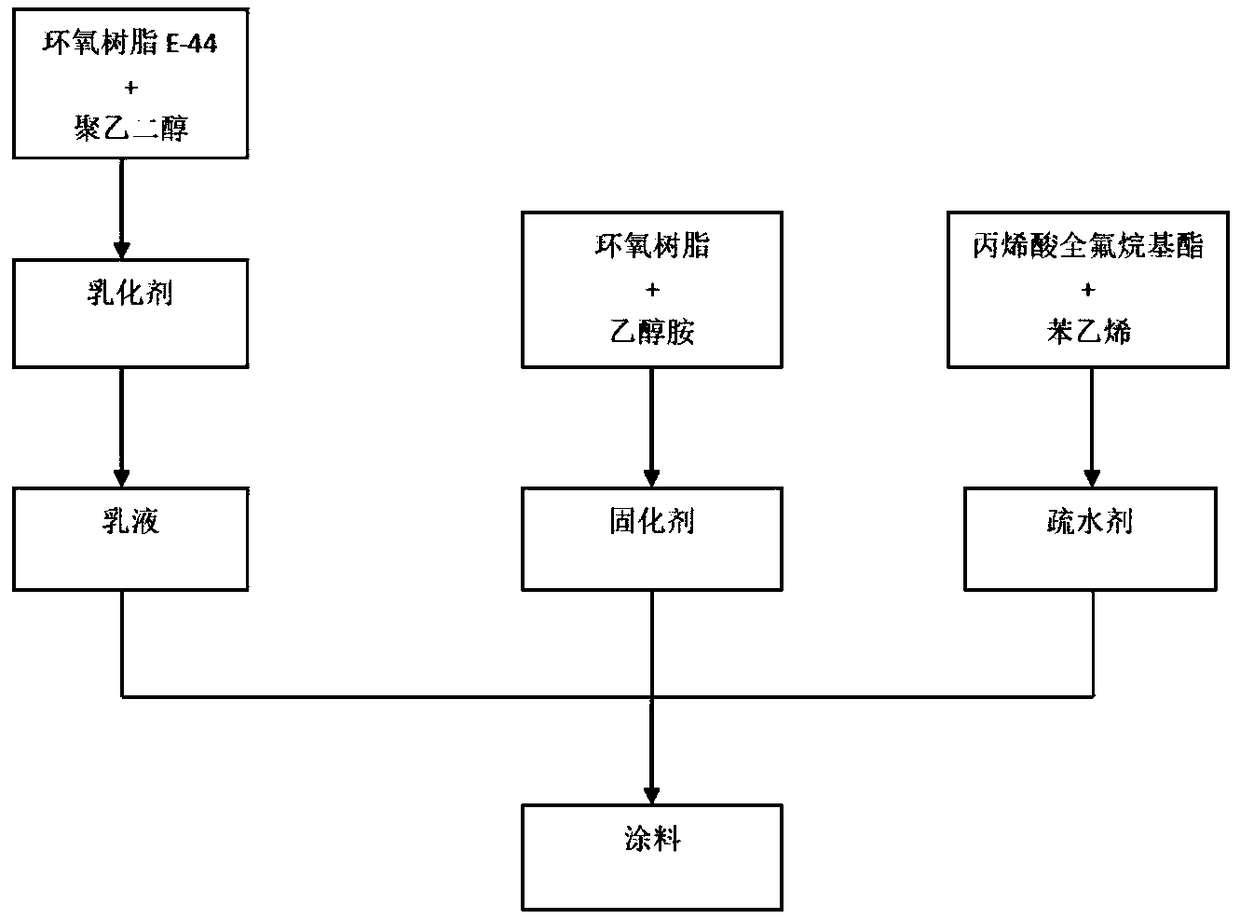

Preparation method of water-borne epoxy resin coating using poly-perfluoroalkyl ethanol-acrylic acid derivative as water repellent agent

A water-based epoxy resin, ethanol acrylic acid technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problem of not having oil-proof performance, and achieve the effect of excellent curing effect, good water resistance, and good superhydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

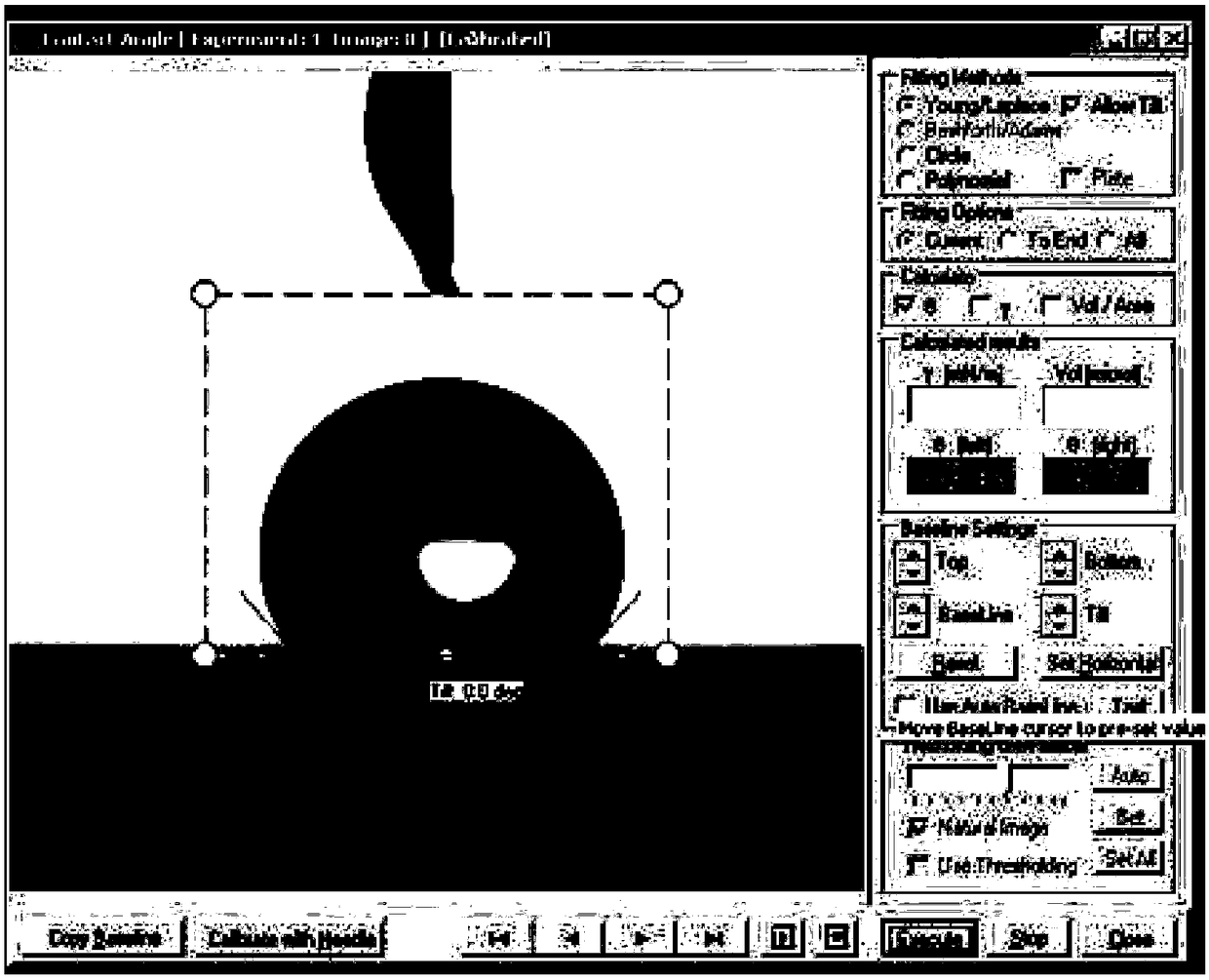

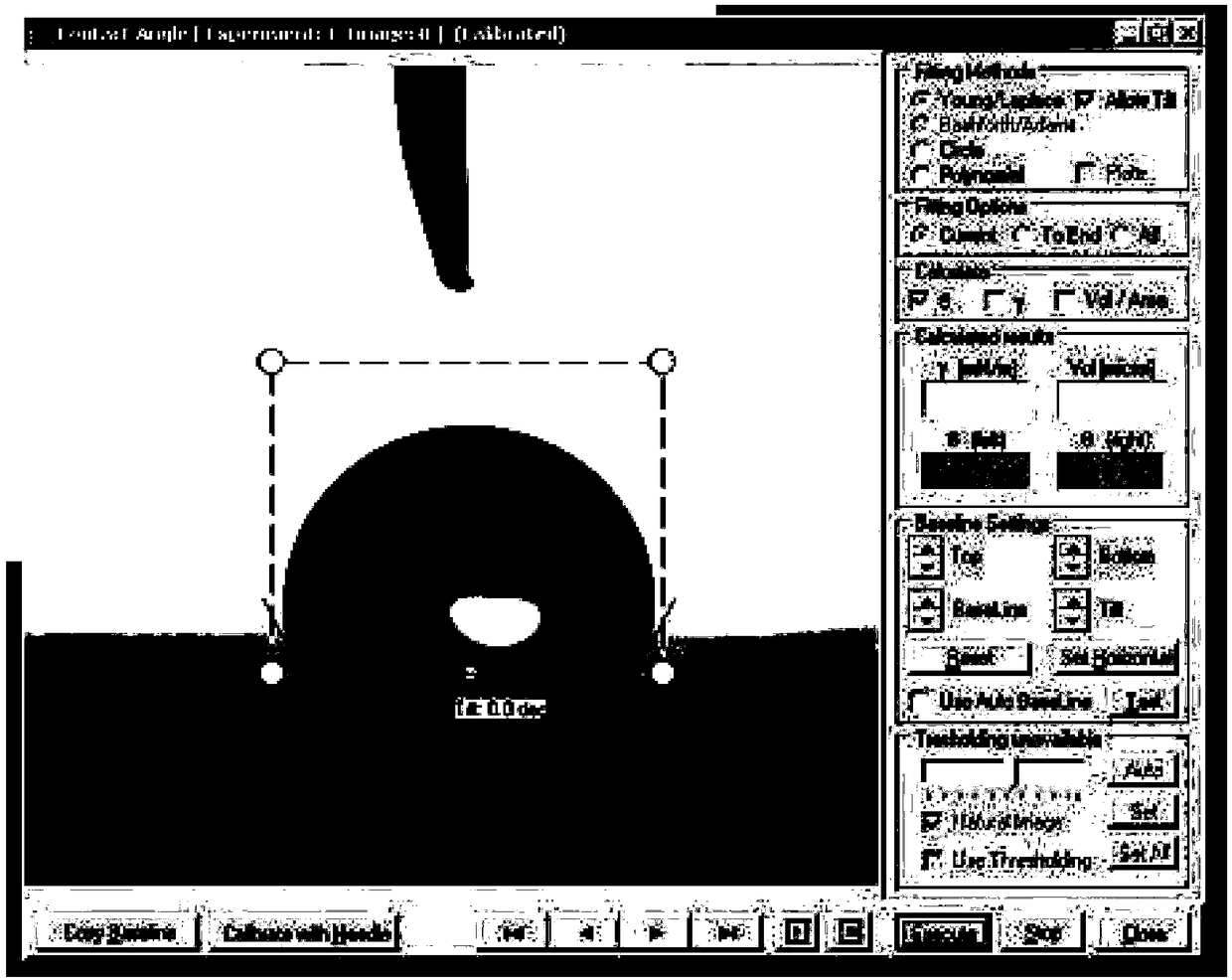

[0018] Synthesis and contact angle test of example 1 perfluoroalkyl acrylate polymer

[0019] Dissolve perfluoroalkylethanol (20.7g, 50mmol) in 50mL of DMF, add 3.75mL of triethylamine as a catalyst, then cool in an ice-water bath, drop in acryloyl chloride (4.85mL, 60mmol), remove the ice water, and react with magnetic stirring for 5 hours , after the end, the reaction solution was poured into 100mL ethyl acetate and 100mL saturated brine, separated, the aqueous phase was extracted three times with 50mL ethyl acetate, the organic phase was combined, washed twice with 100mL saturated brine, and removed by rotary evaporation. solvent to obtain perfluoroalkyl acrylate, 19 g of yellow colloidal solid, yield 81%. 1HNMR (CDCl 3 , 500MHz), δ: 6.46 (d, 1H, CH 2 =), 6.13(m, 1H, -CH=), 4.47(m, 2H, -CH 2 -), 2.55(m, 2H, -CH 2 -).

[0020] Add perfluoroalkyl acrylate (8.91g, 19mmol), styrene (1.98g, 19mmol) and 150mL ethyl acetate into the flask, under nitrogen protection, heat to r...

example 2

[0022] The preparation of example 2 curing agent

[0023] 1.06g of ethanolamine and 2.04g of epoxy resin were dissolved in 10mL of dioxane, heated to 80°C in a water bath, condensed and refluxed for 2h, then 0.08g of sodium hydroxide was added, the reaction was continued for 3h, and 1.69g of a light yellow solid was obtained by evaporation.

example 3

[0024] The preparation of example 3 emulsion

[0025] Under mechanical stirring, put 58.9g E-44 type epoxy resin and 30.0g polyethylene glycol into a 100ml three-necked flask, place it in an oil bath, raise the temperature to 180°C, add 0.76g ammonium persulfate, and keep at 180°C Constant temperature, mechanical stirring for 2 hours to prepare emulsifier, brown liquid. After the temperature dropped to room temperature, the emulsifier solidified and became solid. Put 47.44g of epoxy resin and 9.65g of the above-mentioned emulsifier into the bottle, heat to 60°C in a water bath and keep the temperature constant, add 25g of distilled water at a uniform speed, and stir mechanically for 1 hour to prepare the emulsion.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap