W-Mo-Re-HfC alloy material and preparation method thereof

A technology of w-mo-re-hfc and alloy material, applied in the field of W-Mo-Re-HfC alloy material and its preparation, can solve the problems of insignificant rhenium effect of tungsten-rhenium alloy, unable to meet the requirements of use, etc., and achieve excellent Room temperature and high temperature mechanical properties, overcoming the reduction of mechanical properties, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

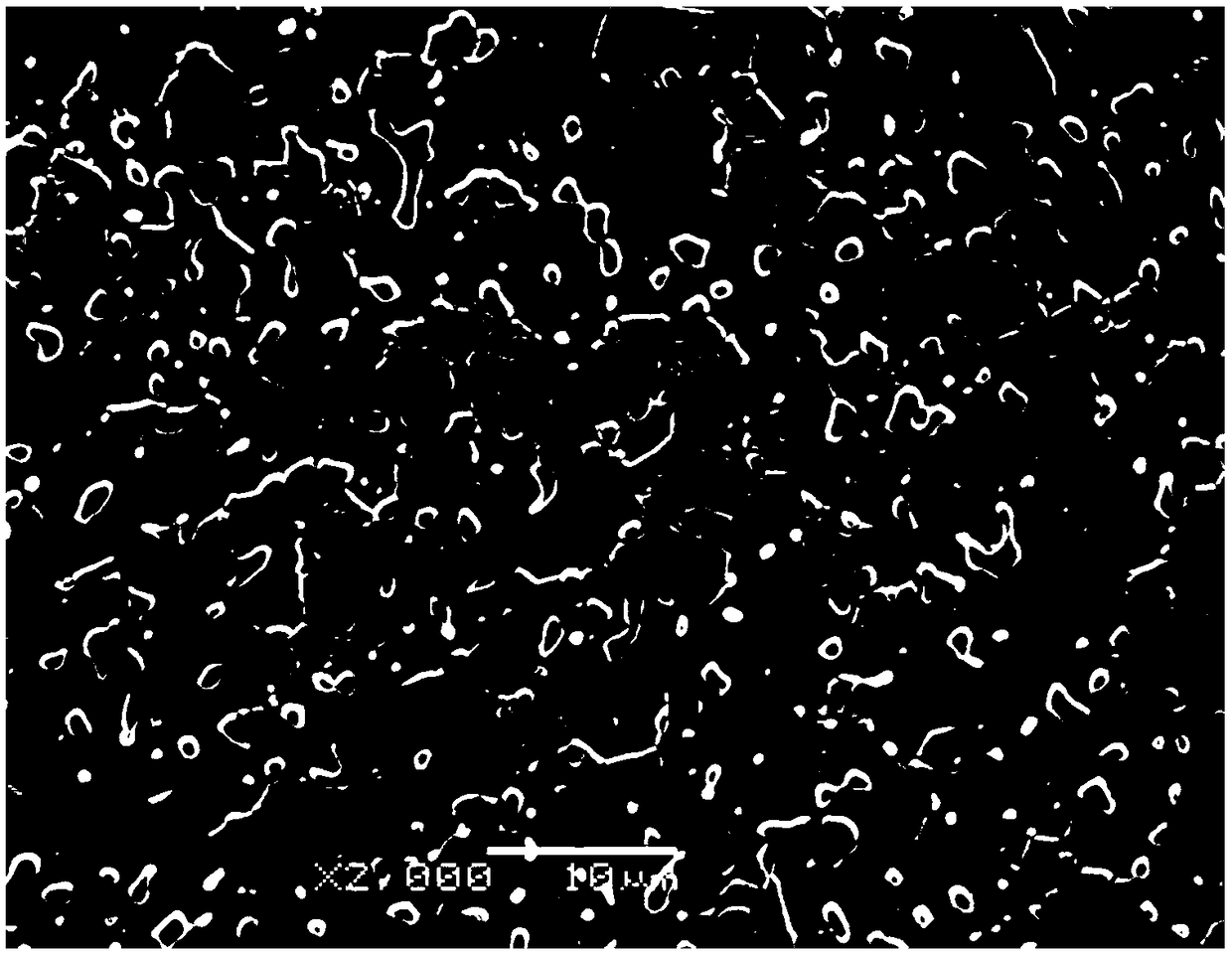

[0022] The W-Mo-Re-HfC alloy material of this embodiment is made of the following raw materials in mass percentage: Mo 10%, Re 25%, HfC 0.2%, and the balance is W and unavoidable impurities.

[0023] The preparation method of the W-Mo-Re-HfC alloy material of the present embodiment comprises the following steps:

[0024] Step 1. Put molybdenum powder, rhenium powder, hafnium carbide powder and tungsten powder in a planetary ball mill and mix them evenly to obtain a composite powder; the mass purity of the molybdenum powder, rhenium powder, hafnium carbide powder and tungsten powder is not less than 99% %; the particle size of the molybdenum powder is not greater than 5 μm, the particle size of the rhenium powder is not greater than 5 μm, the particle size of the hafnium carbide powder is not greater than 1 μm, and the particle size of the tungsten powder is not greater than 6 μm; The ratio is 3:1, and the ball milling time is 10h;

[0025] Step 2. Perform a reduction reaction...

Embodiment 2

[0029] The W-Mo-Re-HfC alloy material of this embodiment is made of the following raw materials in mass percentage: Mo 15%, Re 20%, HfC 1%, the balance is W and unavoidable impurities.

[0030] The preparation method of the W-Mo-Re-HfC alloy material in this embodiment is the same as that in Embodiment 1. The fracture toughness of the W-Mo-Re-HfC alloy material prepared in this example is 38.4MPa m at room temperature of 25°C 1 / 2 , the compressive strength is 2688MPa, the compressive strain is 12%; the compressive strength at 1300°C is 714MPa. At the same time, the W-Mo-Re-HfC alloy material prepared in this embodiment is resistant to erosion and ablation in an ultra-high temperature environment of 2000° C., and meets the requirements for ultra-high temperature use.

Embodiment 3

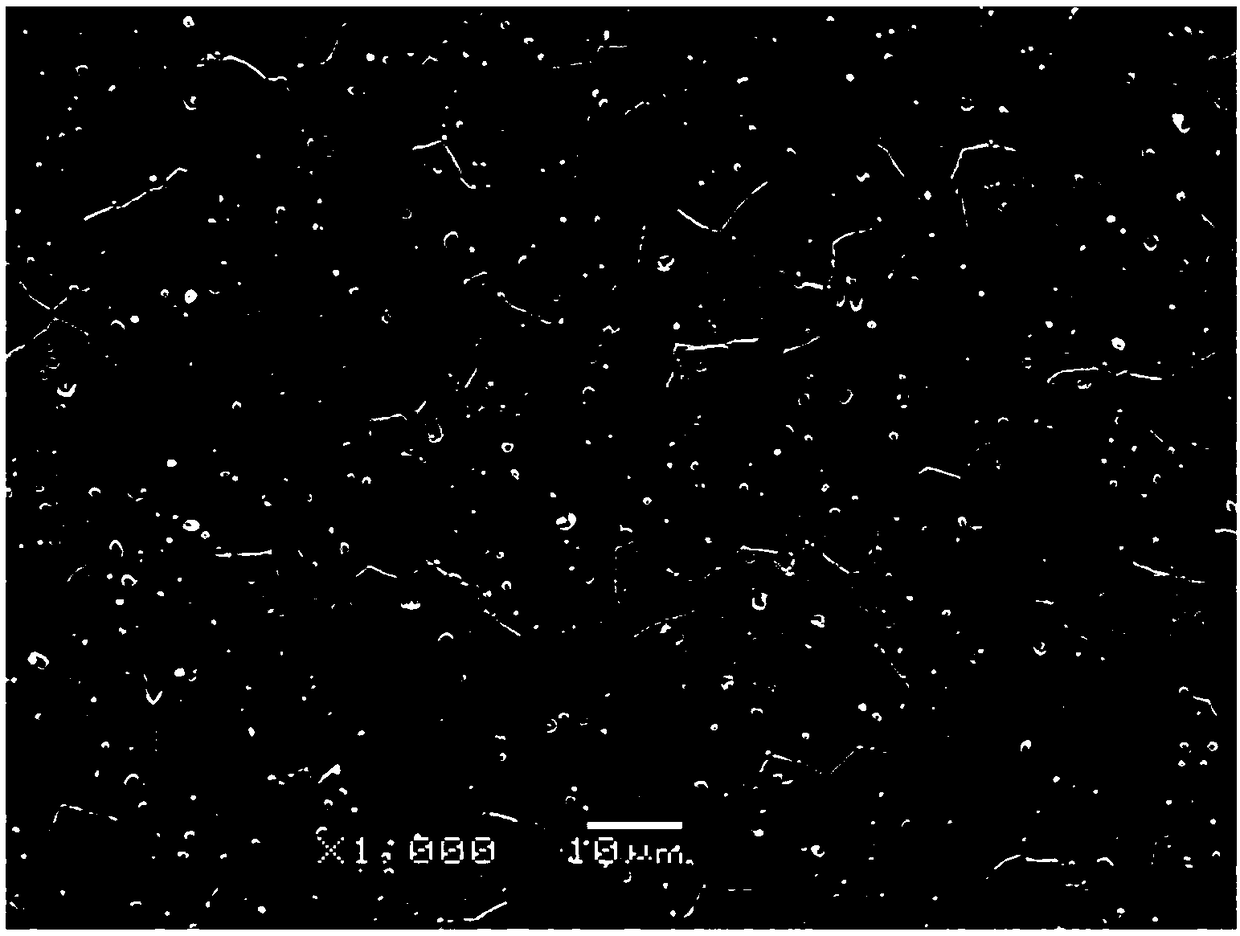

[0032] The W-Mo-Re-HfC alloy material of this embodiment is made of the following raw materials in mass percentage: Mo 20%, Re 13%, HfC 5%, the balance is W and unavoidable impurities.

[0033] The preparation method of the W-Mo-Re-HfC alloy of the present embodiment comprises the following steps:

[0034] Step 1. Put molybdenum powder, rhenium powder, hafnium carbide powder and tungsten powder in a planetary ball mill and mix them evenly to obtain a composite powder; the mass purity of the molybdenum powder, rhenium powder, hafnium carbide powder and tungsten powder is not less than 99% %; the particle size of the molybdenum powder is not greater than 5 μm, the particle size of the rhenium powder is not greater than 5 μm, the particle size of the hafnium carbide powder is not greater than 1 μm, and the particle size of the tungsten powder is not greater than 6 μm; The ratio is 6:1, and the ball milling time is 15h;

[0035] Step 2. Perform a reduction reaction on the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com