Preparation method of colored nylon fishing net thread with excellent comprehensive characteristics

A technology with comprehensive characteristics and fishing net threads, applied in the directions of melt spinning, rayon manufacturing, fiber chemical characteristics, etc., it can solve the problems of poor appearance, poor dye adsorption capacity and adsorption effect, etc., and achieve good appearance and comprehensive quality. Excellent, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

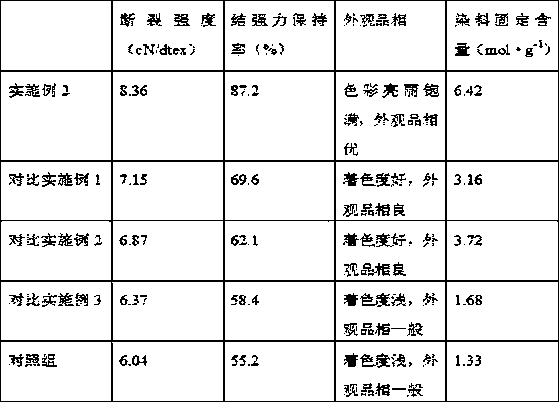

Examples

Embodiment 1

[0030] A method for preparing a colored nylon fishing net line with excellent comprehensive properties, comprising the steps of:

[0031] (1) Preparation of composite functional filler:

[0032] a. First put the montmorillonite into the hydrochloric acid solution for soaking for 3 minutes, then take it out and soak it in the sodium hydroxide solution for 6 minutes, and finally take it out and rinse it with deionized water for later use;

[0033] b. Put the montmorillonite treated in operation a into a high-temperature calciner for calcination, and take it out after 1 hour for later use;

[0034] c. Put the montmorillonite treated in operation b into the ultraviolet irradiator for irradiation treatment, and take it out after 25 minutes for later use;

[0035] d. Immerse the montmorillonite treated in operation c into the modified treatment solution A, and take it out for use after ultrasonic shock treatment for 1 hour; the modified treatment solution A is composed of the follo...

Embodiment 2

[0052] A method for preparing a colored nylon fishing net line with excellent comprehensive properties, comprising the steps of:

[0053] (1) Preparation of composite functional filler:

[0054]a. Put the montmorillonite into the hydrochloric acid solution for soaking for 4 minutes, then take it out and soak it in the sodium hydroxide solution for 7 minutes, and finally take it out and rinse it with deionized water for later use;

[0055] b. Put the montmorillonite treated in operation a into a high-temperature calciner for calcination, and take it out after 1.5 hours for later use;

[0056] c. Put the montmorillonite treated in operation b into the ultraviolet irradiator for irradiation treatment, and take it out after 28 minutes for later use;

[0057] d. Immerse the montmorillonite treated in operation c into the modified treatment solution A, and take it out for use after ultrasonic vibration treatment for 1.6h; the modified treatment solution A is composed of the followi...

Embodiment 3

[0074] A method for preparing a colored nylon fishing net line with excellent comprehensive properties, comprising the steps of:

[0075] (1) Preparation of composite functional filler:

[0076] a. First put the montmorillonite into the hydrochloric acid solution for soaking for 5 minutes, then take it out and soak it in the sodium hydroxide solution for 8 minutes, and finally take it out and rinse it with deionized water for later use;

[0077] b. Put the montmorillonite treated in operation a into a high-temperature calciner for calcination, and take it out after 2 hours for later use;

[0078] c. Put the montmorillonite treated in operation b into the ultraviolet irradiator for irradiation treatment, and take it out after 30 minutes for later use;

[0079] d. Immerse the montmorillonite treated in operation c into the modified treatment solution A, and take it out for use after ultrasonic shock treatment for 2 hours; the modified treatment solution A is composed of the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com