A reinforced film for battery isolation and its preparation method

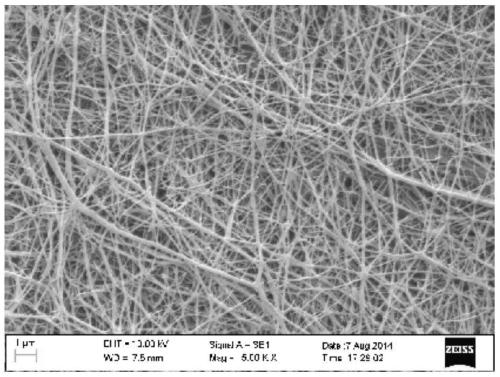

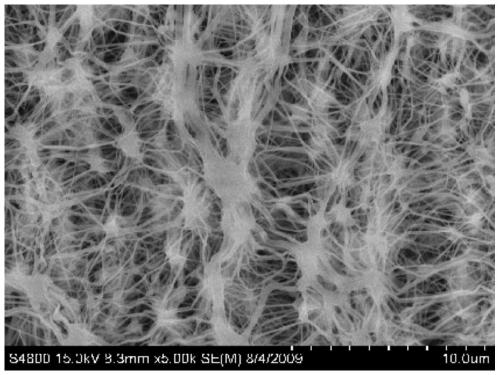

A technology for enhancing membranes and batteries, which is applied to battery components, chemical instruments and methods, membranes, etc., can solve the problem that the isolation membrane cannot withstand the strong oxidation and degradation of free radicals in the battery, and achieve a small difference in elastic modulus , fewer nodules, smaller pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Material: DuPont 601A PTFE fine powder is used.

[0034] Processing steps:

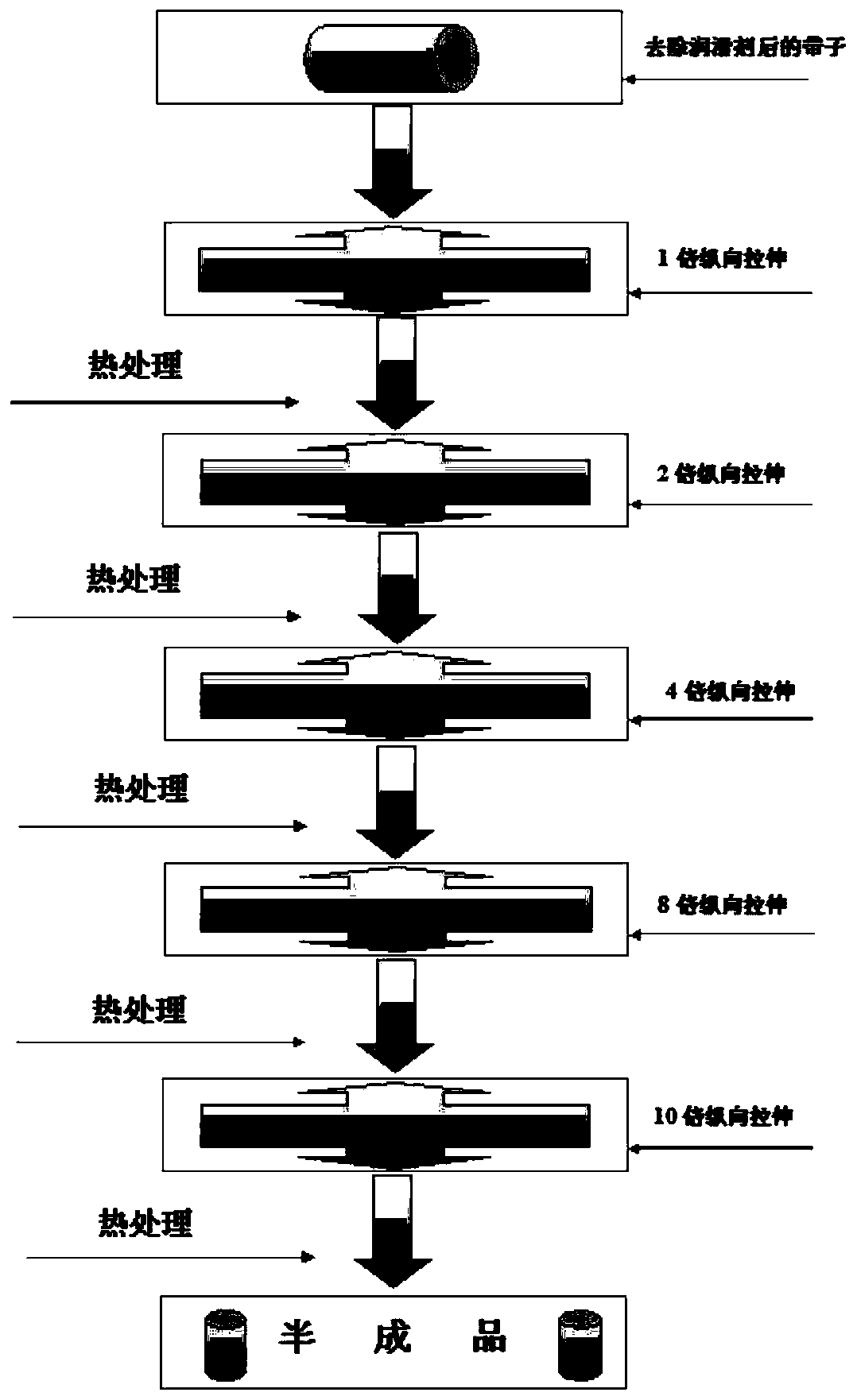

[0035] Mixing-push-pressing-extrusion-calendering-lubricant removal-multiple longitudinal stretching-heat treatment-cooling setting-transverse stretching-heat setting-cooling setting.

[0036] Specifically:

[0037] (1) Mixing: Take an appropriate amount of polytetrafluoroethylene (PTFE) powder, add lubricant Isopar in a proportion of 25%, stir well, pour it into a heat preservation bucket after sieving, and keep it warm at 40°C for 24 hours.

[0038] (2) Pushing: Under a pressure of 2Mpa, push the heat-preserved PTFE fine powder into a cylindrical blank.

[0039] (3) Extrusion: Extrude the cylindrical billet into a continuous strip-shaped film with a width of 180 mm and a thickness of 2.0 mm at 40° C. with a fishtail die.

[0040] (4) Calendering: The width of the film remains unchanged, and it is rolled longitudinally to a PTFE strip film with a thickness of 0.2 mm.

[0041] (5) Lubricant r...

Embodiment 2

[0053] Material: Daikin F106C PTFE fine powder is used.

[0054] Processing steps: mixing - pushing - extrusion - calendering - removal of lubricant - longitudinal stretching - heat treatment - cooling setting - transverse stretching - heat setting - cooling setting.

[0055] Specifically:

[0056] (1) Mixing: Take an appropriate amount of polytetrafluoroethylene (PTFE) powder, add lubricant Isopar in a proportion of 25%, stir well, pour it into a heat preservation bucket after sieving, and keep it warm at 60°C for 36 hours.

[0057] (2) Pushing: Under a pressure of 6Mpa, push the heat-retaining PTFE fine powder into a cylindrical blank.

[0058] (3) Extrusion: Extrude the cylindrical billet into a continuous strip-shaped film with a width of 180 mm and a thickness of 2.0 mm at 60° C. with a fishtail die.

[0059] (4) Calendering: The width of the film remains unchanged, and it is rolled longitudinally to a PTFE strip film with a thickness of 0.2mm.

[0060] (5) Lubricant r...

Embodiment 3

[0075] Material: DuPont 601A PTFE fine powder is used.

[0076] Processing steps:

[0077] Mixing - Pushing - Extruding - Calendering - Removing lubricant - Longitudinal stretching - Heat treatment - Cooling and setting - Transverse stretching - Heat setting - Cooling and setting.

[0078] Specifically:

[0079] (1) Mixing: Take an appropriate amount of polytetrafluoroethylene (PTFE) powder, add lubricant Isopar in a proportion of 25%, stir well, pour it into a heat preservation bucket after sieving, and keep it warm at 80°C for 48 hours.

[0080] (2) Pushing: Under a pressure of 10Mpa, push the heat-retaining PTFE fine powder into a cylindrical blank.

[0081] (3) Extrusion: Extrude the cylindrical billet into a continuous strip-shaped film with a width of 180 mm and a thickness of 2.0 mm at 80° C. with a fishtail die.

[0082] (4) Calendering: The width of the film remains unchanged, and it is rolled longitudinally to a PTFE strip film with a thickness of 0.2mm.

[0083]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com