Preparation method of sodium-ion battery modified titanium dioxide-graphene anode material

A sodium ion battery, graphene anode technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. Atomic doping and other problems, to achieve excellent cycle stability, improved sodium ion transport capacity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the modified titanium dioxide-graphene negative electrode material for sodium ion battery in this embodiment includes the following steps: 1) adding 1 g of tetrabutyl titanate to 240 ml of absolute ethanol, and then adding 25 ml of 5 mg / ml The graphene aqueous solution was stirred at room temperature for 8h.

[0029] 2) After the stirring, the mixed solution is centrifuged, the obtained precipitate is freeze-dried for 24 hours, and the composite nanosheet of titanium dioxide / graphene is obtained after drying.

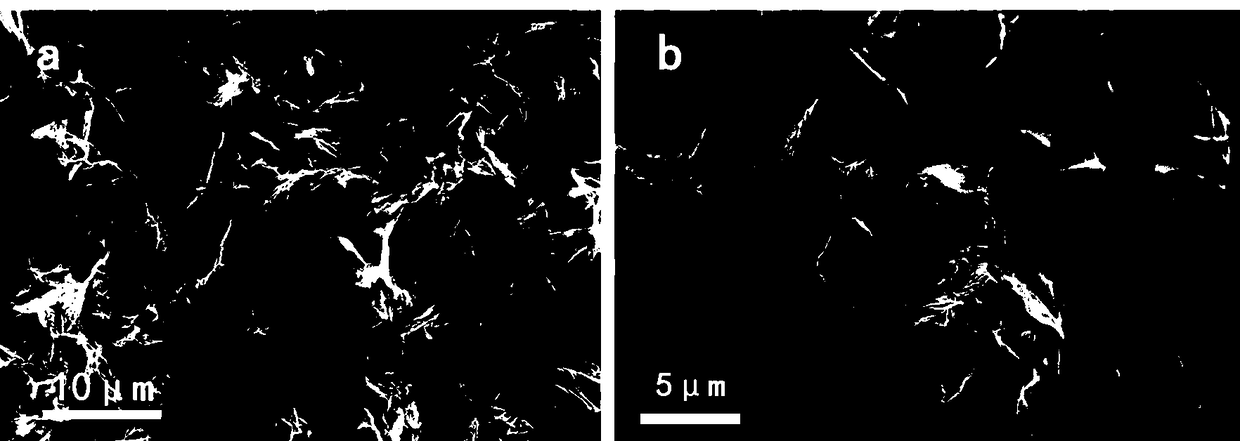

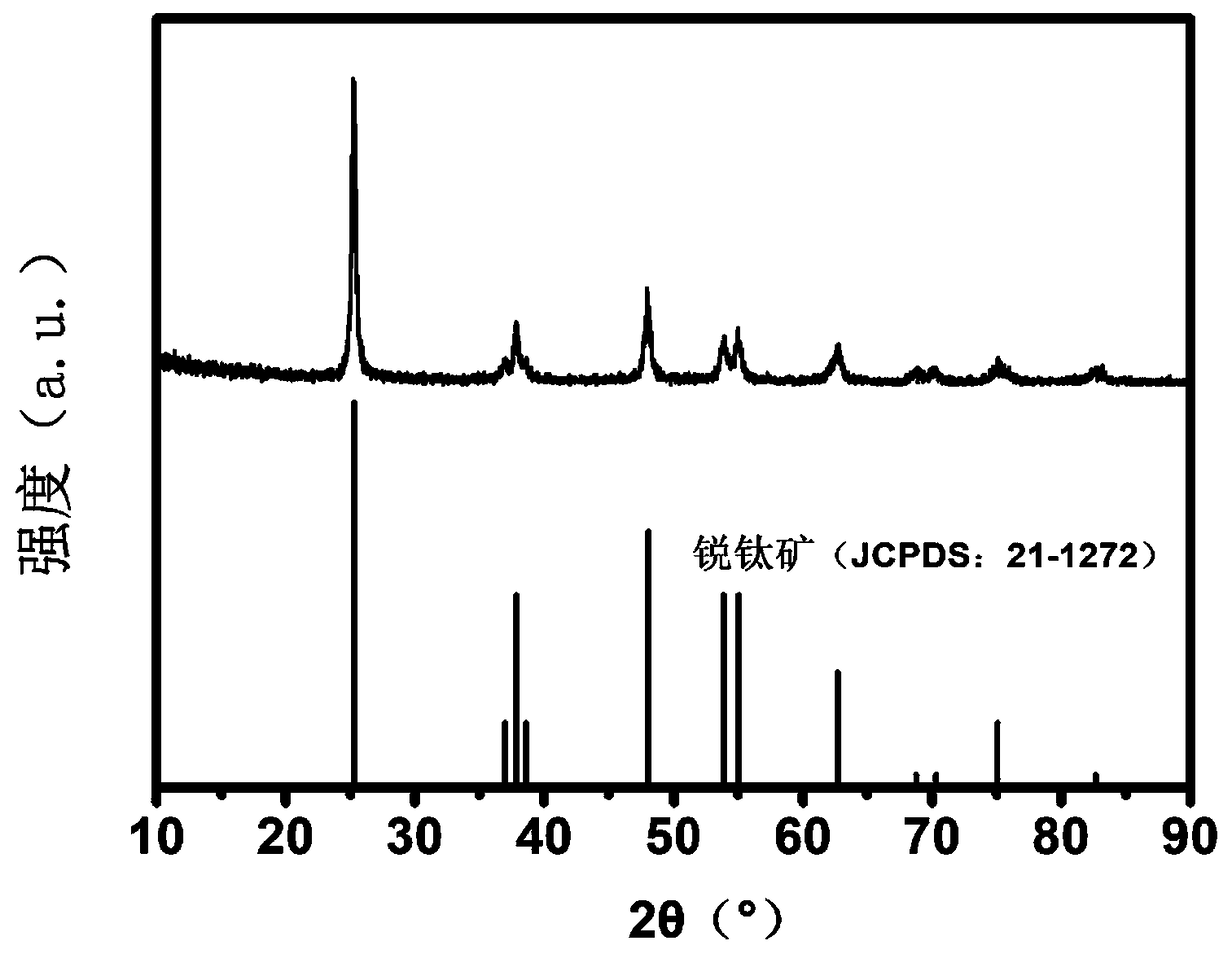

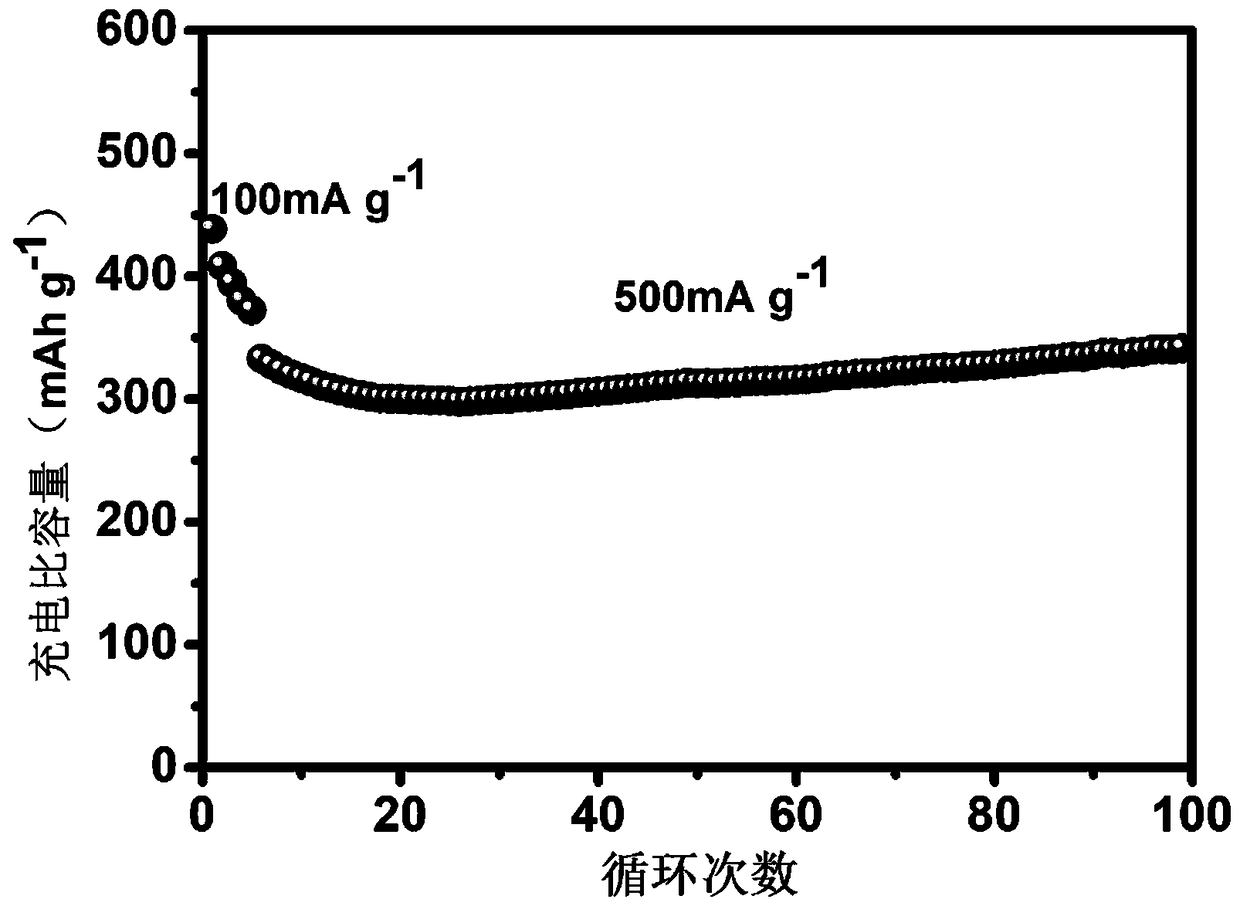

[0030] 3) Phosphating the titanium dioxide / graphene composite nanosheets obtained in the above steps, the phosphorus source used is sodium hypophosphite, and argon gas is introduced as a protective gas, and the temperature is raised to 400°C at a heating rate of 2°C / min. , the holding time is 5h, and the phosphorus-doped titanium dioxide / graphene composite nanosheets are obtained after cooling. figure 1 The SEM image of the phosphorus-d...

Embodiment 2

[0034] The preparation method of the sodium ion battery modified titanium dioxide-graphene negative electrode material of the present embodiment comprises the following steps:

[0035] 1) Add 1g of tetrabutyl titanate to 240ml of absolute ethanol, then add 25ml of graphene aqueous solution with a concentration of 5mg / ml, and stir at room temperature for 8h.

[0036] 2) After the stirring, the mixed solution is centrifuged, the obtained precipitate is freeze-dried for 24 hours, and the composite nanosheet of titanium dioxide / graphene is obtained after drying.

[0037] 3) Phosphating the titanium dioxide / graphene composite nanosheets obtained in the above steps, the phosphorus source used is sodium hypophosphite, and argon gas is introduced as a protective gas, and the temperature is raised to 500°C at a heating rate of 2°C / min. , the holding time is 5h, and the phosphorus-doped titanium dioxide / graphene composite nanosheets are obtained after cooling.

Embodiment 3

[0039] The preparation method of the sodium ion battery modified titanium dioxide-graphene negative electrode material of the present embodiment comprises the following steps:

[0040] 1) Add 1g of tetrabutyl titanate to 240ml of absolute ethanol, then add 10ml of graphene aqueous solution with a concentration of 5mg / ml, and stir at room temperature for 8h.

[0041] 2) After the stirring, the mixed solution is centrifuged, the obtained precipitate is freeze-dried for 24 hours, and the composite nanosheet of titanium dioxide / graphene is obtained after drying.

[0042] 3) Phosphating the titanium dioxide / graphene composite nanosheets obtained in the above steps, the phosphorus source used is sodium hypophosphite, and argon gas is introduced as a protective gas, and the temperature is raised to 350°C at a heating rate of 2°C / min. , the holding time is 5h, and the phosphorus-doped titanium dioxide / graphene composite nanosheets are obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com