Straw mushroom culture method

A cultivation method and straw mushroom technology are applied in mushroom cultivation, botanical equipment and methods, cultivation and other directions, which can solve problems such as affecting the quality and yield of fruiting products, poor air permeability of culture materials, environmental problems, etc. The production environment is safe and hygienic, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

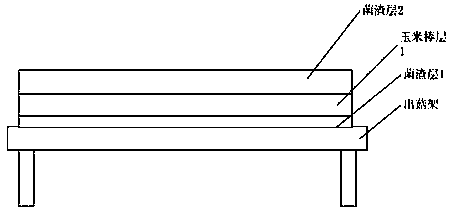

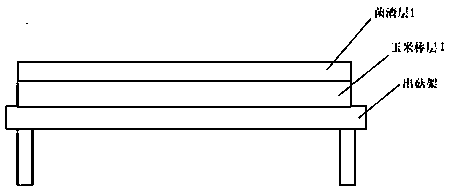

Image

Examples

Embodiment 1

[0054] The cultivation method of straw mushroom comprises the following steps:

[0055] (1) Culture material pretreatment

[0056] Bacteria residue fermentation: Mix the bacteria residue and 5% lime, add an appropriate amount of water according to the material-to-water ratio of 1:1.5, mix well and build a pile for fermentation; when building a pile, the pile height is 55cm, the width is 1.2m, and the length is about 2m. Drill air holes at intervals of 30cm on the surface of the heap, the diameter of the air holes is about 12cm, and the temperature of the fermentation material reaches 60°C and above, keep it for 24 hours, use a turning machine to turn the pile for the first time, when the pile temperature rises to 60°C again, keep it for 24 hours, and then proceed to the second pile. Turn over the pile for the second time. When the pile temperature rises to 60°C for the third time, keep it for 22 hours, then use a turning machine to turn over the pile for the third time, and th...

Embodiment 2

[0104] The cultivation method of straw mushroom comprises the following steps:

[0105] (1) Culture material pretreatment

[0106] Bacterial residue fermentation: mix the bacterial residue and 5% lime, add appropriate amount of water according to the ratio of material to water 1:1.5, mix well and build a pile for fermentation; when building a pile, the pile height is 50cm, the width is about 1m, and the length is about 2m. Air holes are drilled at intervals of 30cm on the surface of the heap, the diameter of the air holes is about 12cm, the temperature of the fermentation material reaches 60°C and above, keep it for 22 hours, use a turning machine to turn the pile for the first time, and when the pile temperature rises to 60°C again, keep it for 22 hours, then carry out the second Turn over the pile for the second time. When the pile temperature rises to 60°C for the third time, keep it for 22 hours, then use a turning machine to turn over the pile for the third time, and then...

Embodiment 3

[0124] The cultivation method of straw mushroom comprises the following steps:

[0125] (1) Culture material pretreatment

[0126] Bacterial residue fermentation: Mix the bacterial residue and 5% lime, add appropriate amount of water according to the ratio of material to water 1:1.5, mix well and build a pile for fermentation; when building a pile, the pile height is 60cm, the width is about 1.5m, and the length is about 3m. Air holes are drilled at intervals of 30cm on the surface of the material pile. The diameter of the air hole is about 15cm. When the temperature of the fermentation material reaches above 65°C, keep it for 24 hours. Turn over the pile for the second time, when the temperature of the pile rises to 65°C for the third time, keep it for 24 hours, then use a turning machine to turn over the pile for the third time, and then transport it to the fruiting room while it is hot for spreading;

[0127] Turn over 3 times in total, and the fermentation period is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com