High-capacity high-rate graphite negative pole material used for lithium ion battery and preparation method thereof

A lithium-ion battery, graphite anode technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of poor electrolyte compatibility, high pollution, difficult to control the graphite layer spacing, etc. Mild processing technology and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

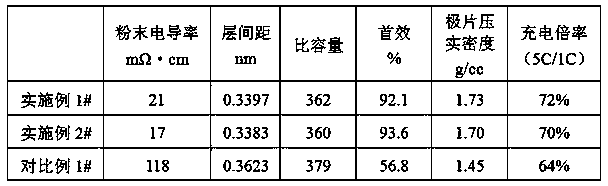

Examples

Embodiment 1

[0020] A preparation method of high-capacity, high-rate graphite negative electrode material for lithium-ion batteries, the steps are as follows:

[0021] (I) Petroleum asphalt and biomass tar with a softening point of 120°C and D50=3.5 μm were used as raw materials, in which aromatic hydrocarbons accounted for 21% of biomass tar, phenols accounted for 45%, and the mass ratio of asphalt to tar was 100:8. Under nitrogen atmosphere, 300 rpm mechanical stirring, and 400° C., polycondensation and crosslinking were carried out for 12 hours to obtain a crosslinked mesophase pitch.

[0022] (II) The cross-linked mesophase pitch was treated in a nitrogen atmosphere at a low temperature of 600 °C for 5 hours, and the temperature was naturally cooled to room temperature. The resulting green coke was depolymerized by multiple round mills, and then classified to obtain a precursor with D50=15 μm.

[0023] (Ⅲ) The precursor is graphitized under a nitrogen atmosphere at 3000°C for 2 hours ...

Embodiment 2

[0025] A preparation method of high-capacity, high-rate graphite negative electrode material for lithium-ion batteries, the steps are as follows:

[0026] (I) Coal tar pitch and biomass tar with a softening point of 200°C and D50=4.4 μm were used as raw materials, in which aromatic hydrocarbons accounted for 32% of biomass tar, phenols accounted for 40%, and the mass ratio of pitch to tar was 100:3. Under the conditions of argon atmosphere, 300rpm mechanical stirring, and 450°C, polycondensation and crosslinking were carried out for 24 hours to obtain a crosslinked mesophase pitch.

[0027] (II) The cross-linked mesophase pitch was treated in an argon atmosphere at a low temperature of 600 °C for 3 h, and the temperature was naturally cooled to room temperature. The resulting green coke was depolymerized by multiple round mills, and then classified to obtain a precursor with D50=15 μm.

[0028] (Ⅲ) The precursor is graphitized under an argon atmosphere at 3200°C for 2 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com