Preparation method of three-dimensional porous carbon

A three-dimensional porous, dopamine technology, applied in the field of porous materials, can solve the problems of complex methods, difficult to prepare in large quantities, and many steps, and achieve the effects of simplifying process steps, avoiding purification steps, and reducing equipment loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of the three-dimensional porous carbon of the present invention, comprising the following steps:

[0031] Mix the sugar source, dopamine and ammonium chloride evenly, raise the resulting mixture from room temperature to 250°C~300°C under the protection of an inert atmosphere, then accelerate the temperature rise to 800°C~1200°C, and then sinter at constant temperature for 2h~ 6h, cooled to room temperature to obtain a self-supporting three-dimensional porous carbon.

[0032] In the above preparation method, the mass ratio of sugar source and dopamine is 4~100:1 (i.e. 99:1~80:20), the ratio of the total mass of sugar source and dopamine to the mass of ammonium chloride is 0.2~5:1 (ie 1:5 ~ 5:1).

[0033] In the above preparation method, when the room temperature rises to 250°C to 300°C, the heating rate is 1°C / min to 10°C / min, and the temperature is kept for 0 to 3 hours; in the accelerated and continuous heating stage, the heating rate is 2°C / min t...

Embodiment 1

[0037] A preparation method of the three-dimensional porous carbon of the present invention, comprising the following steps:

[0038] Mix 2 g of glucose, 0.1 g of dopamine, and 2 g of ammonium chloride evenly, and place the resulting mixture in a tube furnace. min continued to rise to 1000°C, kept at a constant temperature for 3 hours, and then naturally cooled to room temperature to obtain a self-supporting three-dimensional porous carbon.

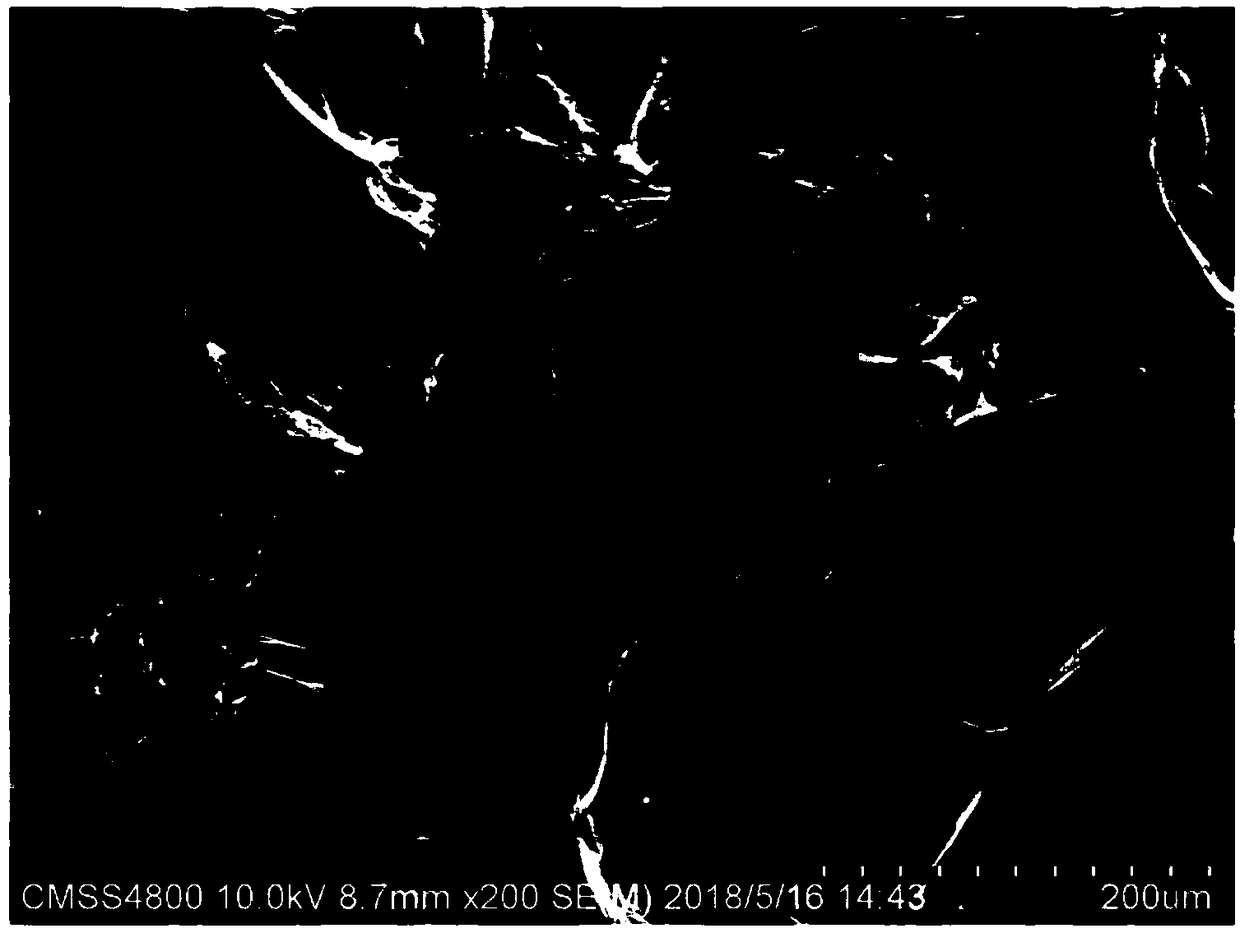

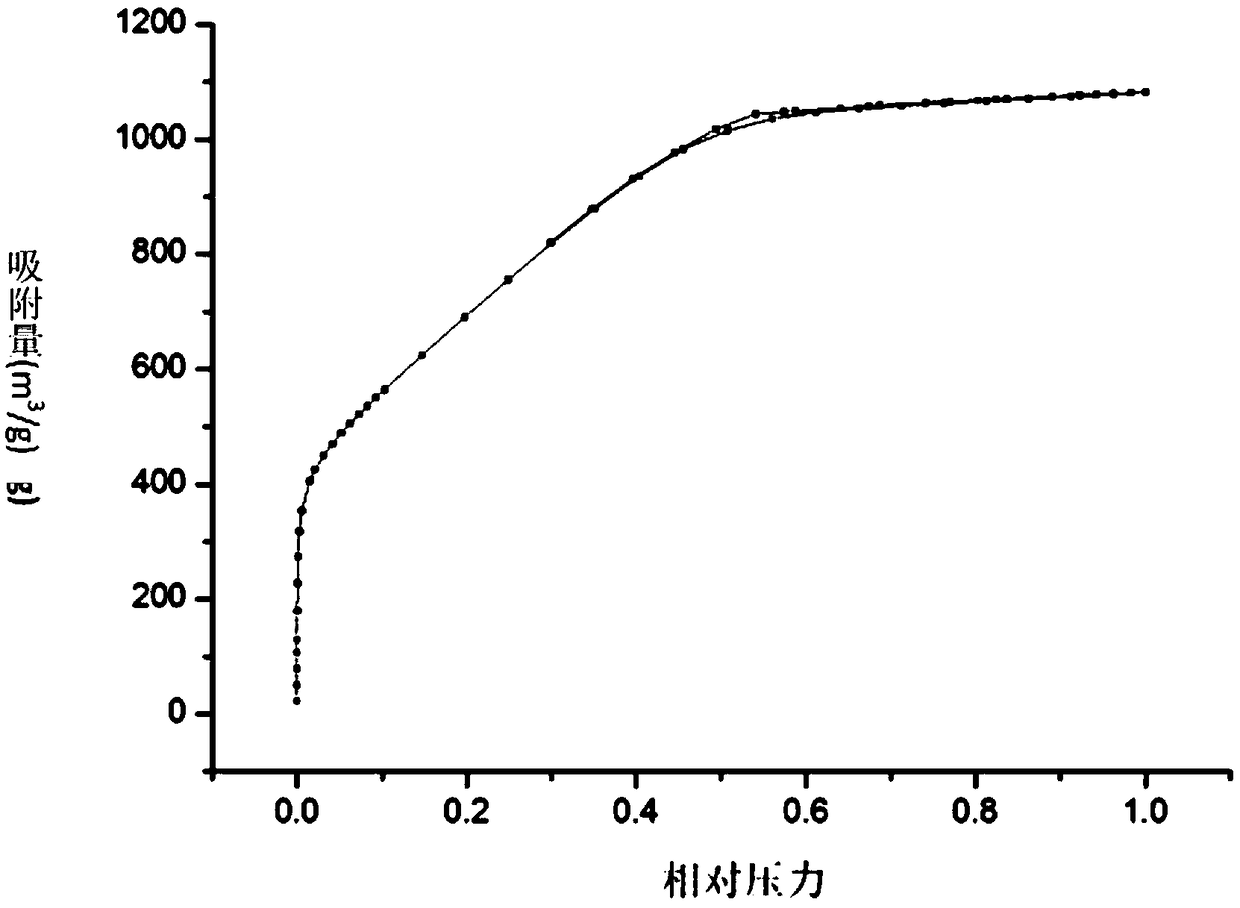

[0039] Characterize the self-supporting three-dimensional porous carbon prepared in this example, figure 1 is an optical photograph of three-dimensional porous carbon, figure 2 As a scanning electron microscope photo, it can be seen that there are many channel structures on the surface of the sample. image 3 is the nitrogen adsorption-desorption curve of the sample, and the BET specific surface area is 2600m 2 / g.

Embodiment 2

[0041] A preparation method of the three-dimensional porous carbon of the present invention, comprising the following steps:

[0042] Mix 2 g of glucose, 0.02 g of dopamine and 2 g of ammonium chloride evenly, place the resulting mixture in a tube furnace, and under the condition of nitrogen protection, first raise the temperature from room temperature to 250 °C at 2 °C / min, keep it warm for 2 hours, and then Continue to heat up to 1000°C at 8°C / min, keep the temperature for 3 hours, and then cool down to room temperature naturally to obtain a self-supporting three-dimensional porous carbon.

[0043] Characterize the self-supporting three-dimensional porous carbon prepared in this example, Figure 4 is an optical photograph of a self-supporting 3D porous carbon, Figure 5 As a scanning electron microscope photo, it can be seen that there are many channel structures on the surface, Figure 6 is the nitrogen adsorption-desorption curve of the sample, and the BET specific surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com